Sewage treatment device, method and system

A technology of sewage treatment device and sewage treatment method, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. Sewage treatment effect and COD reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

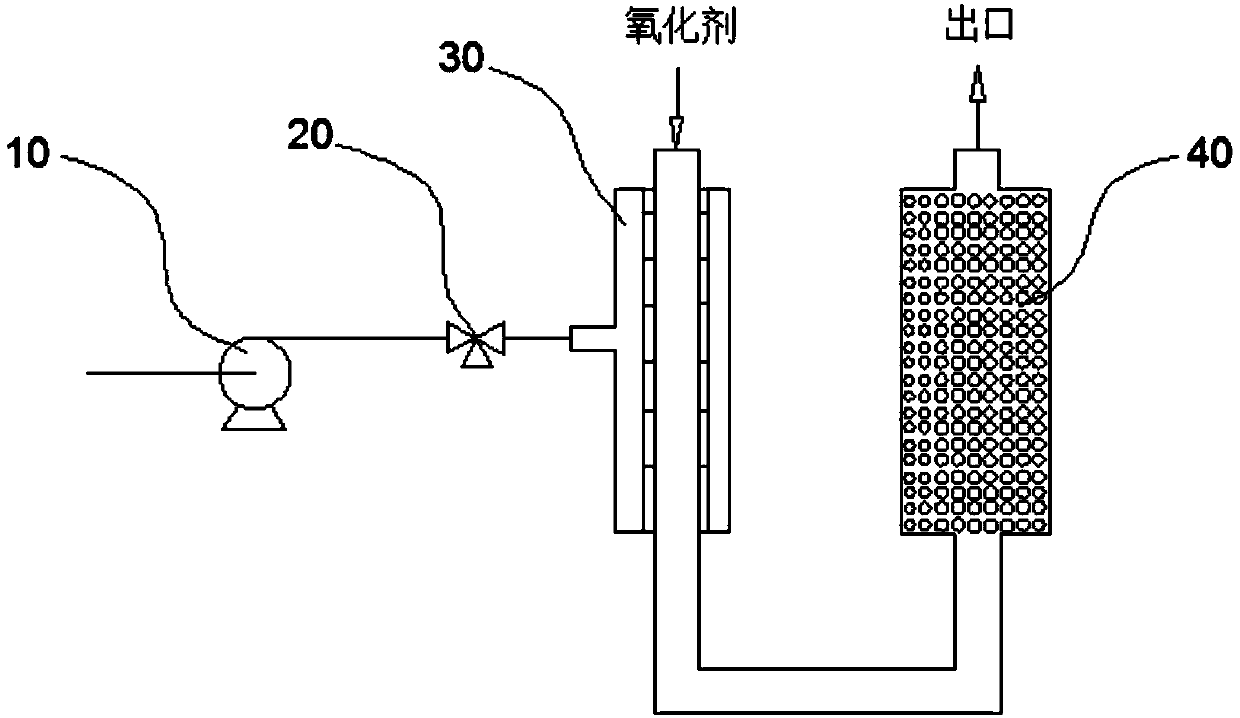

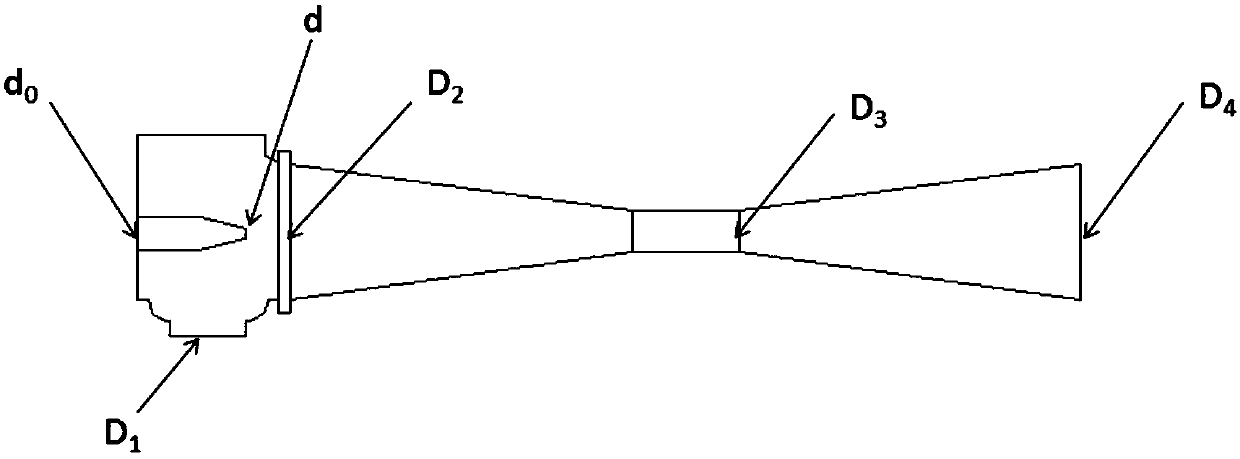

[0073] Such as figure 1 As shown, the present embodiment is a sewage treatment device, including a gas-liquid mixing unit and an oxidation unit 40 connected to the gas-liquid mixing unit; the gas-liquid mixing unit includes a sewage pump 10, a gas-liquid ejector 20 and a gas-liquid mixing Device 30; the gas-liquid mixer 30 includes five mixing columns, and the mixing column is provided with helical blades. The gas-liquid mixer 30 has an aspect ratio of 0.12 and a volume fraction of 15%. Wherein, the air-liquid ejector 20 is a conventional type air-liquid ejector. The oxidation unit 40 includes a fixed-bed catalytic oxidation column, wherein the fixed-bed catalytic oxidation column is filled with catalytic packing, and the volume of the catalytic packing is 23% of the column volume. The catalytic filler includes alumina, inorganic binder, organic binder and manganese dioxide, and the specific surface area of alumina is 400m 2 / g. The ratio of the column diameter of the fi...

Embodiment 2

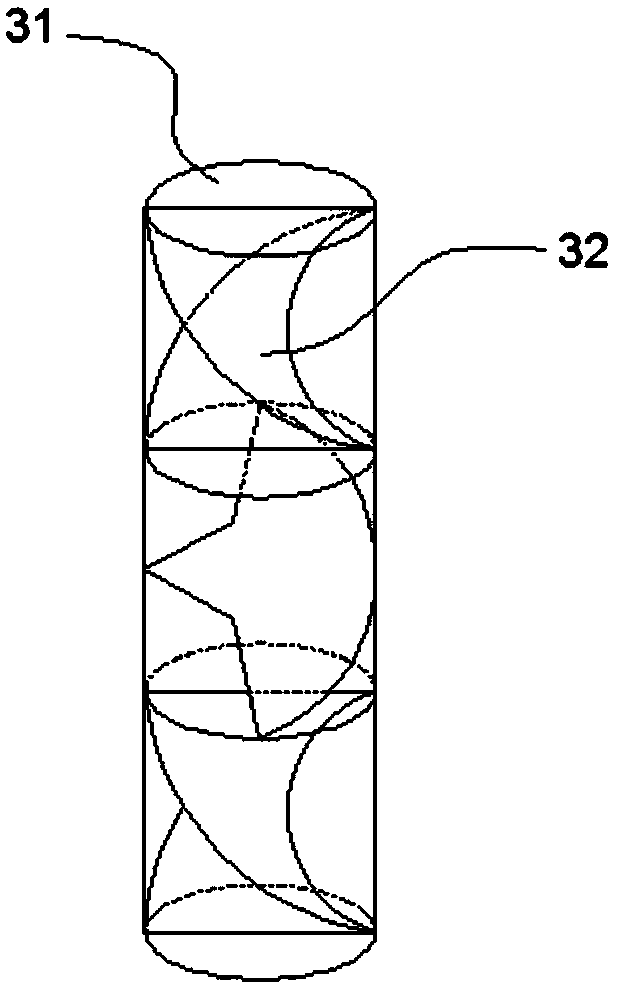

[0075]This embodiment is a sewage treatment device, comprising a gas-liquid mixing unit and an oxidation unit connected to the gas-liquid mixing unit; the gas-liquid mixing unit includes a sewage pump, a gas-liquid jet, and a gas-liquid mixer connected in sequence; the gas-liquid mixer It includes five mixing columns with helical blades inside. The helical blades include left helical blades and right helical blades, the left helical blades and right helical blades are alternately arranged in the mixing column along the axial direction of the mixing column, and the left helical blades and right helical blades are alternately arranged in the mixing column at an angle of 30° , and the helical blade is a 180° twisted helical blade. The aspect ratio of the gas-liquid mixer is 0.12, and the volume fraction is 15%. Wherein, the gas-liquid ejector is a conventional type of gas-liquid ejector. The oxidation unit includes a fixed-bed catalytic oxidation column, wherein the fixed-bed c...

Embodiment 3

[0077] This embodiment is a sewage treatment device, and the difference from Embodiment 2 is that the helical blade 32 in the mixing column 31 is divided into a left helical blade and a right helical blade, wherein the left helical blade and the right helical blade are separated by 90 in the mixing column 31. ° Angle misalignment is set alternately, such as figure 2 Shown, others are identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com