Composite fireproof anticorrosive cable bridge and preparation method thereof

A cable tray and composite technology, applied in the direction of chemical instruments and methods, electrical components, adhesive additives, etc., can solve the problems of being easily corroded by water or other substances, poor fire resistance, poor corrosion resistance, etc., to improve the resistance Corrosion performance, strong anti-aging performance, and the effect of improving fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

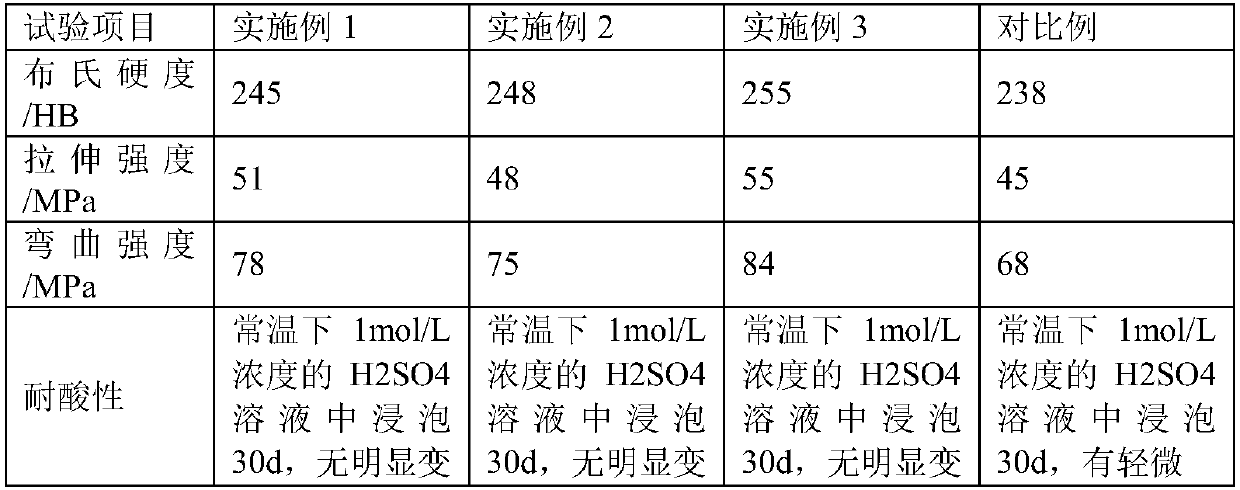

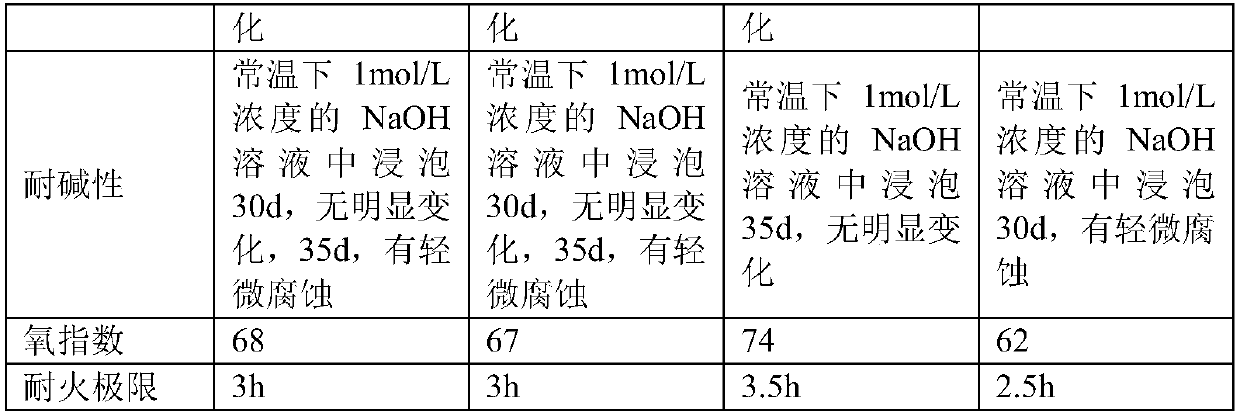

Examples

Embodiment 1

[0030] This embodiment provides a composite fire-resistant and anti-corrosion cable tray, including a base material layer, a fire-proof layer, an anti-corrosion layer and a rubber layer. The base material layer is coated with a rubber layer, and the rubber layer is bonded with a fire-proof layer. , the exterior of the fireproof layer is coated with a rubber layer, and the rubber layer is bonded with an anti-corrosion layer;

[0031] The chemical composition percentage of the base material layer is: C: 0.38-0.47%, Si: 0.28-0.34%, Ni: 5.4-6.2%, Nb: 0.28-0.35%, Ti: 0.88-1.12%, Mn: 0.55-0.62% , Mg: 6.63-7.25%, Al: 2.68-3.45%, B: 0.15-0.19%, Ce: 0.02-0.04%, and the balance is Fe;

[0032] The raw material components of the fireproof layer include by weight: 25-36 parts of aluminum oxide, 16-18 parts of magnesium oxide, 50-60 parts of polypropylene, 15-20 parts of aluminum hydroxide, 4-6 parts of liquid paraffin, 25-30 parts Part glass fiber, 6-8 parts refractory filler, 16-18 part...

Embodiment 2

[0041] This embodiment provides a composite fire-resistant and anti-corrosion cable tray, including a base material layer, a fire-proof layer, an anti-corrosion layer and a rubber layer. The base material layer is coated with a rubber layer, and the rubber layer is bonded with a fire-proof layer. , the exterior of the fireproof layer is coated with a rubber layer, and the rubber layer is bonded with an anti-corrosion layer;

[0042] The chemical composition percentage of the base material layer is: C: 0.38-0.47%, Si: 0.28-0.34%, Ni: 5.4-6.2%, Nb: 0.28-0.35%, Ti: 0.88-1.12%, Mn: 0.55-0.62% , Mg: 6.63-7.25%, Al: 2.68-3.45%, B: 0.15-0.19%, Ce: 0.02-0.04%, and the balance is Fe;

[0043] The raw material components of the fireproof layer include by weight: 25-36 parts of aluminum oxide, 16-18 parts of magnesium oxide, 50-60 parts of polypropylene, 15-20 parts of aluminum hydroxide, 4-6 parts of liquid paraffin, 25-30 parts Part glass fiber, 6-8 parts refractory filler, 16-18 part...

Embodiment 3

[0052] This embodiment provides a composite fire-resistant and anti-corrosion cable tray, including a base material layer, a fire-proof layer, an anti-corrosion layer and a rubber layer. The base material layer is coated with a rubber layer, and the rubber layer is bonded with a fire-proof layer. , the exterior of the fireproof layer is coated with a rubber layer, and the rubber layer is bonded with an anti-corrosion layer;

[0053] The chemical composition percentage of the base material layer is: C: 0.38-0.47%, Si: 0.28-0.34%, Ni: 5.4-6.2%, Nb: 0.28-0.35%, Ti: 0.88-1.12%, Mn: 0.55-0.62% , Mg: 6.63-7.25%, Al: 2.68-3.45%, B: 0.15-0.19%, Ce: 0.02-0.04%, and the balance is Fe;

[0054] The raw material components of the fireproof layer include by weight: 25-36 parts of aluminum oxide, 16-18 parts of magnesium oxide, 50-60 parts of polypropylene, 15-20 parts of aluminum hydroxide, 4-6 parts of liquid paraffin, 25-30 parts Part glass fiber, 6-8 parts refractory filler, 16-18 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com