Method for conversion of heavy oil to light fractions at low temperature, system for conversion of heavy oil to light fractions at low temperature, and application

A technology for lightening and heavy oil, applied in cracking, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of low yield of light oil, high energy consumption, complex process, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

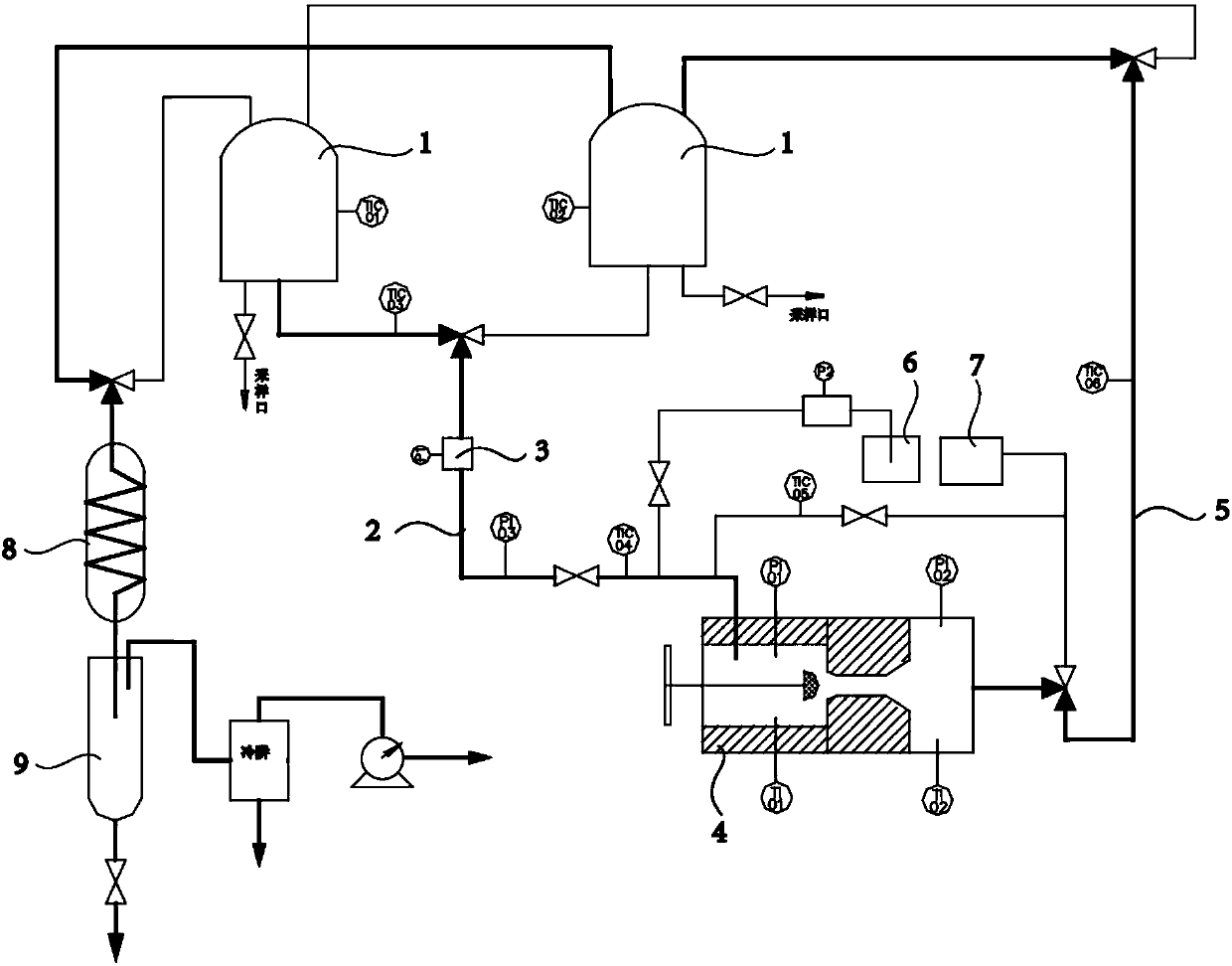

[0059] As a preferred embodiment of the present invention, the heavy oil low-temperature lightening system includes a heavy oil storage tank 1, an oil inlet pipeline 2, a lightening device 4 and an oil return pipeline 5, specifically as figure 1 shown;

[0060] The heavy oil storage tank 1 communicates with the lightweight device 4 through the oil inlet pipeline 2, and the lightweight device 4 communicates with the heavy oil storage tank 1 through the oil return pipeline 5;

[0061] The oil inlet pipeline 2 is also provided with a heavy oil pump 3, which is used to pressurize the heavy oil to the inlet of the lightening device 4 and maintain a certain pressure of the heavy oil.

[0062] The present invention provides a low-temperature lightening system for heavy oil, which includes a heavy oil storage tank 1, an oil inlet pipeline 2, a heavy oil pump 3, a lightening device 4, and an oil return pipeline 5. The inlet of the lightening device 4 maintains a certain pressure, and ...

Embodiment 1

[0081] A low-temperature lightening method for heavy oil provided in this embodiment includes the following steps:

[0082] (a) Heat Tahe crude oil in the heavy oil storage tank to 50°C, pump it into the inlet of the lightening device through the heavy oil pump, and keep the inlet pressure of the heavy oil at 2.0Mpa;

[0083] (b) The heavy oil enters the lightening device for lightening treatment, and its outlet pressure is normal pressure after passing through the lightening device;

[0084] The gas product obtained after the lightening treatment is discharged, cooled to obtain light oil, and the heavy oil after the lightening treatment is subjected to the above-mentioned cycle treatment once (that is, the heavy oil undergoes two lightening treatments).

Embodiment 2

[0086] The low-temperature lightening method of heavy oil provided in this example is the same as that of Example 1, except that the Tahe crude oil is heated to 80° C. in a heavy oil storage tank. For details, please refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com