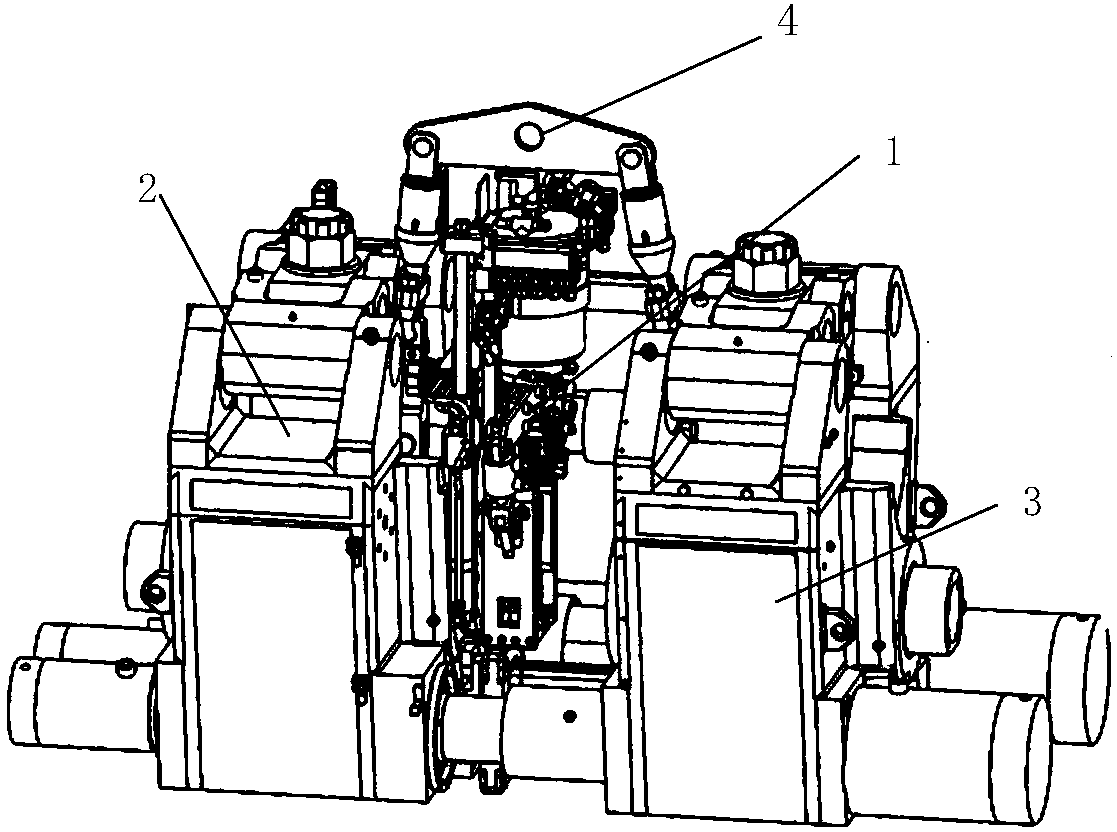

Suspension type flash butt welding and medium-frequency heat treatment mechanism for steel rails

A flash butt welding and suspension technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as inability to achieve heat treatment, large heat treatment head, heating coil cooling system and large intermediate frequency transformer, etc., to achieve effective isolation , to ensure toughness and avoid embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

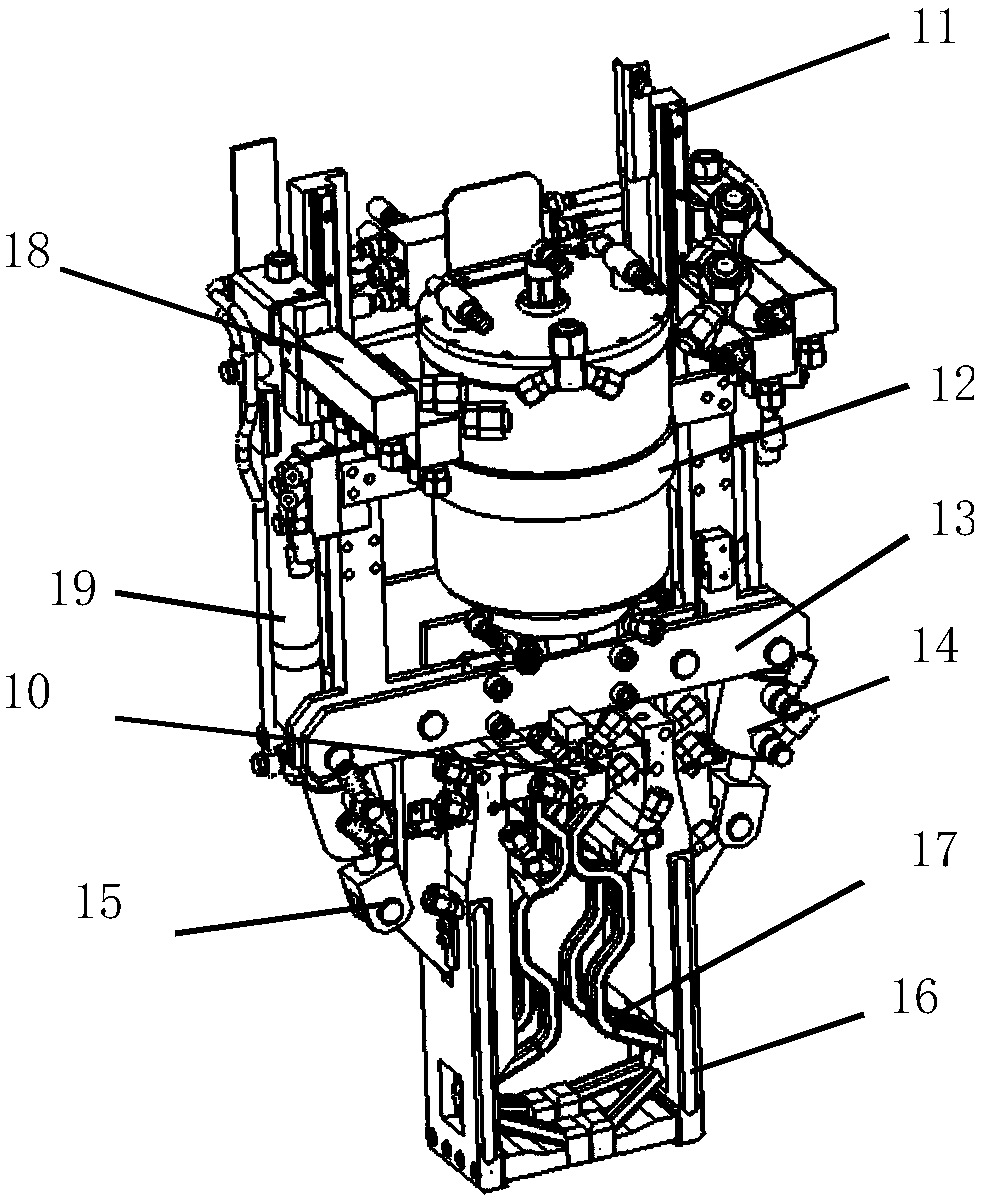

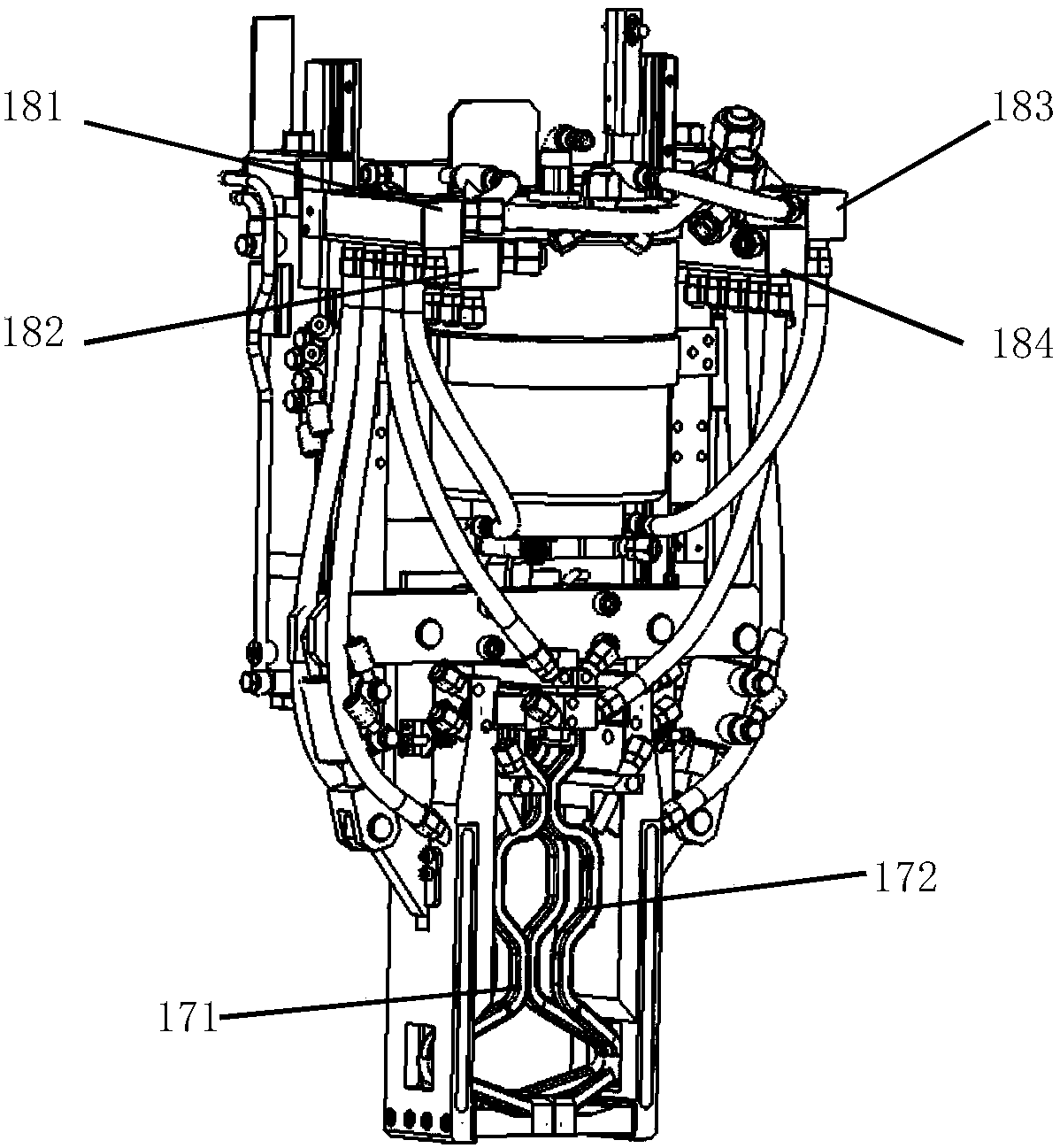

[0037] When the rail is welded, the coil lifting cylinder in the medium frequency induction heating mechanism is in an extended state, and the medium frequency heating coil and the medium frequency transformer on the coil lifting frame are at the highest position of the linear bearing track. Since the heat treatment is medium-frequency alternating current, the ferromagnetic spatter generated during welding will generate heat when the heat treatment is heated, and in serious cases will directly cause a short circuit. Therefore, welding spatter must be strictly prevented.

[0038] Fix two symmetrical upsetting shaft slag plates on the upsetting shaft of the welding machine respectively. One insulating end of the upsetting shaft slag plate is fixed on the moving frame, and the other insulating end is placed on the static frame upsetting sleeve. superior. Then place the horizontal slag retaining plate on the top of the two upsetting shaft slag retaining plates, connect with the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com