High water pressure soft soil stratum HFE combined type shield starting method

A high hydraulic pressure, combined technology, applied in the direction of earth drilling, underground chamber, wellbore lining, etc., can solve the problem that the soft soil cutter head does not have the ability to break the underground diaphragm wall, the surrounding rock and soil self-stabilization ability is poor, and the danger Personnel safety and other issues, to achieve the effect of reducing the risk of shield tunneling, strengthening the self-stability of the formation, and reducing the lateral water and soil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

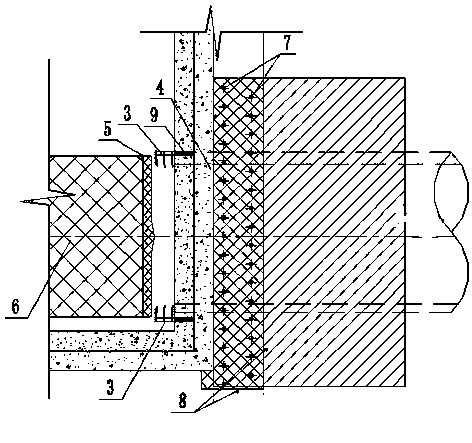

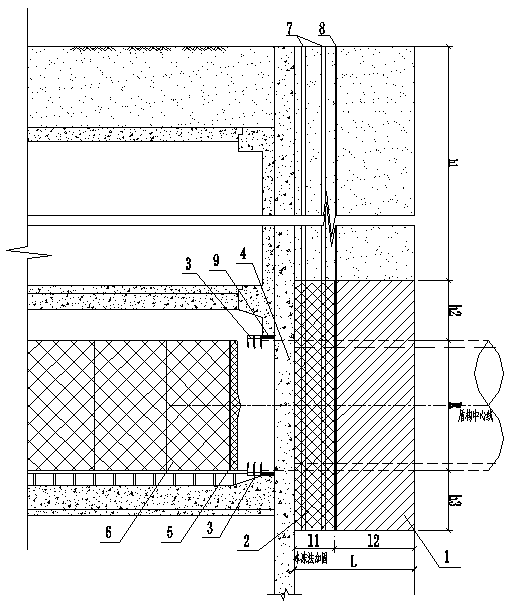

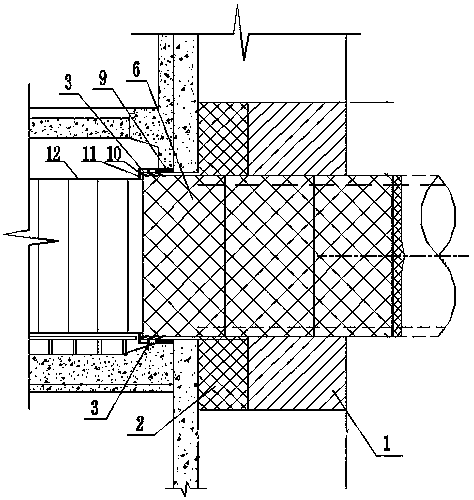

[0043] In conjunction with accompanying drawing, the specific embodiment of the present invention is further described:

[0044] like Figure 1 ~ Figure 4 The method shown is a combined shield tunneling method for high hydraulic pressure soft soil formation (HFE), which is suitable for all water-rich formations, but in soft soil formations with high water head, large water volume, and no precipitation conditions for initiation The medium advantage is particularly obvious, and the described starting method comprises the following steps:

[0045] S1. Calculate the reinforcement length according to hydrogeological conditions and water and soil pressure. In general, the outside diameter of the shield (left and right lines) is 3.0m, and the bottom and top are within 3.0m of the reinforcement area. The reinforcement length is based on the water and soil pressure after the door is broken. The calculations ensure that the reinforced soil must have good uniformity and self-supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com