Rotary kiln automatic feeding system and control method thereof

An automatic feeding and rotary kiln technology, applied in the field of feeding systems, can solve the problems of unstable working conditions, inability to visually observe the amount of material added, and valves that cannot be closed normally, and achieve the effect of ensuring air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

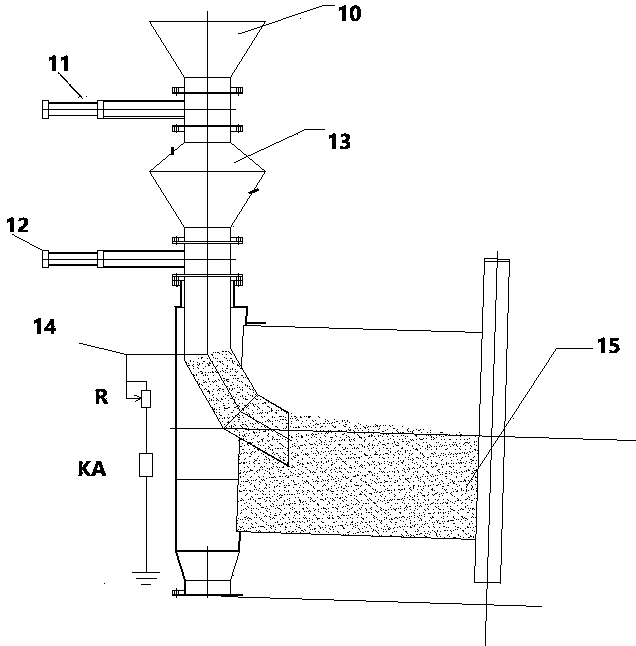

[0019] The specific technical solutions of the present invention will be described below with reference to the accompanying drawings.

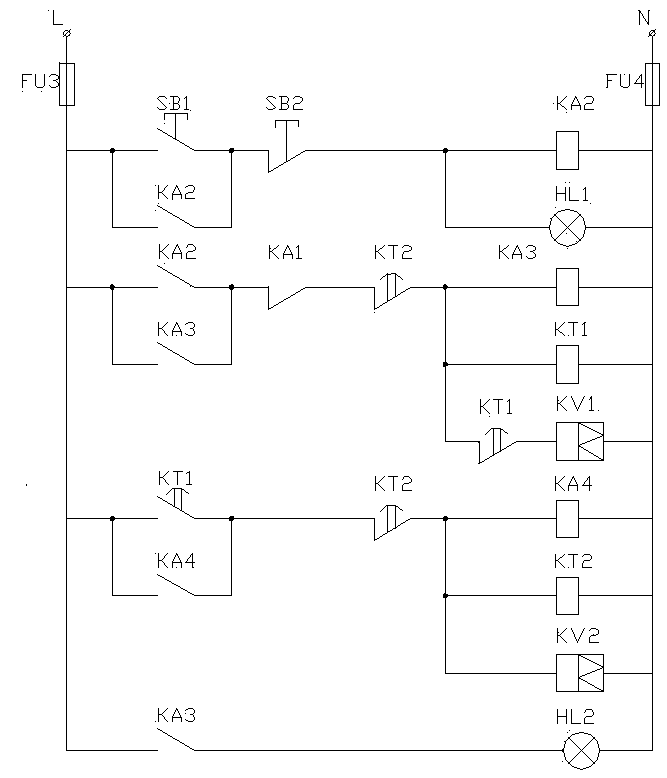

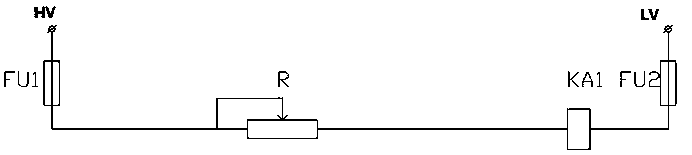

[0020] The technical solution of the present invention is an automatic feeding system for a rotary kiln, figure 1 It is a structural representation of the present invention. The automatic feeding system of the rotary kiln includes a kiln barrel, a feed pipe 16 extending to the inside of the kiln barrel preheating section, a sealed bin 13 connected to the upper end of the feed pipe, a feeding bin 10 set on the upper part of the sealed bin 13, and the inlet and outlet of the sealed bin 13 respectively The upper closed valve 11 and the lower closed valve 12 are set, the low material level sampling probe 14 is arranged in the feed pipe 16, the material in the feeding bin 10 is conductive material, and the other end of the material level sampling probe 14 is sequentially connected to a sampling valve. Resistor R, intermediate relay KA, said inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com