Single-mode optical fiber with low attenuation and large effective area

An effective area, single-mode fiber technology, applied in clad fibers, multi-layer core/clad fibers, light guides, etc. Attenuation coefficient, good dispersion, effect of reducing specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described and illustrated in detail below in conjunction with embodiments.

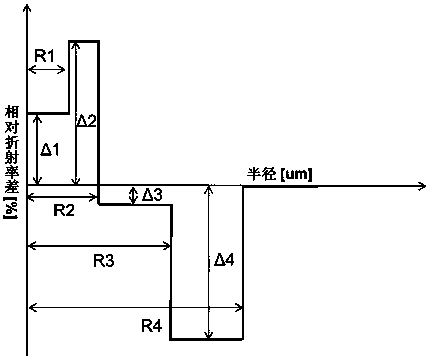

[0037] The refractive index profile structure distribution of an embodiment of the present invention is as figure 1 As shown, including a core layer and a cladding layer, the core layer includes a depressed inner core layer and an outer core layer, the depressed inner core layer is located at the center of the optical fiber, and the radius is r 1 , The relative refractive index difference is Δn 1 , The outer core layer tightly wraps the sunken inner core layer, the radius is r 2 , The relative refractive index difference is Δn 2 The core layer is covered with a cladding layer, the cladding layer includes an inner cladding layer, a sinking cladding layer and an outer cladding layer from the inside to the outside, and the inner cladding layer has a radius of r 3 , The relative refractive index difference is Δn 3 , The radius of the sunken cladding is r 4 , The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com