A safety limit control method for focusing mechanism

A control method and safe technology, applied in installation, instrument, optics and other directions, can solve the problems of inappropriate camera focusing mechanism, the operation of focusing mechanism cannot be directly observed, etc., achieve good real-time performance, prevent mechanical collision, The effect of reducing the impact of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation method of the present invention is as follows:

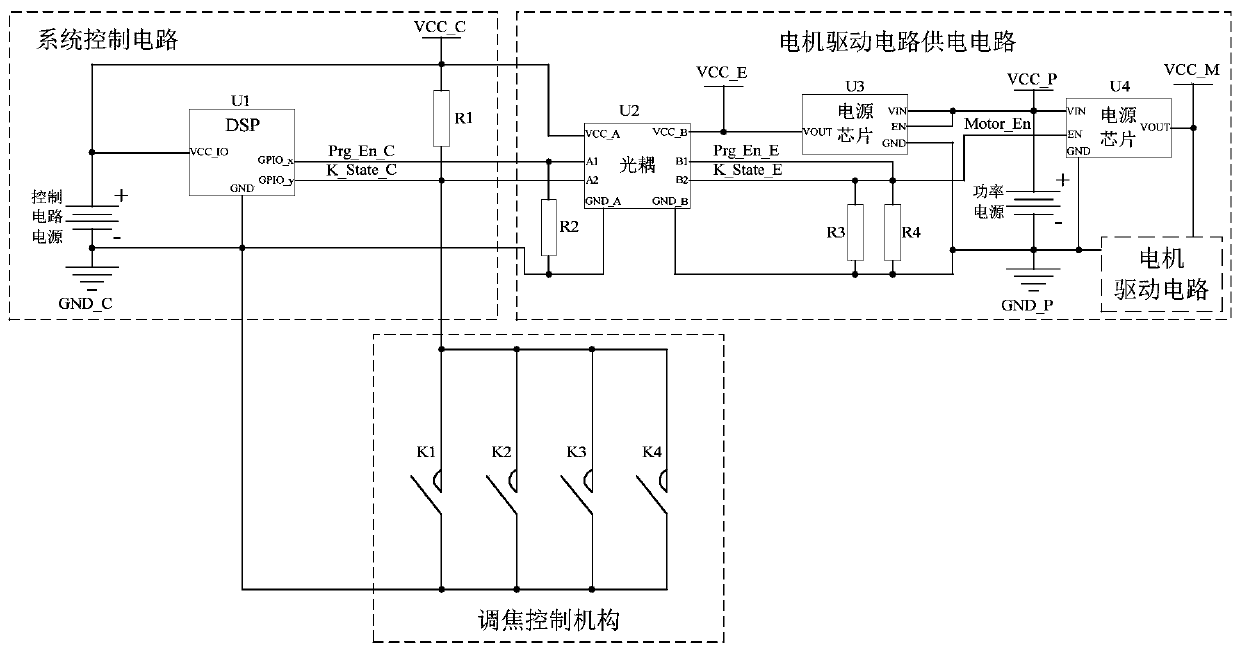

[0026] One limit switch is installed at the left and right limit positions of at least one stroke interval of the focusing mechanism, and the normally closed contacts of all limit switches (at least two) are suspended, and the normally open contacts are connected to the reference ground of the system control circuit. After the output terminals of all limit switches are short-circuited, a "limit state feedback" signal is generated, which is pulled up to the power supply of the system control circuit through a resistor in the system control circuit. At this time, the "multi-channel OC gate line AND" logic output formed by the limit switch and the pull-up resistor, that is, when any limit switch output becomes low, the "limit status feedback" signal outputs a low level. The "limit status feedback" signal is used to drive the GPIO pin of the control system processor and a signal input pin of the dual optocoupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com