Lithium battery positive and negative materials ceramic cutting die

A positive and negative electrode and lithium battery technology, applied in the field of punching dies, to achieve high toughness, good punching effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

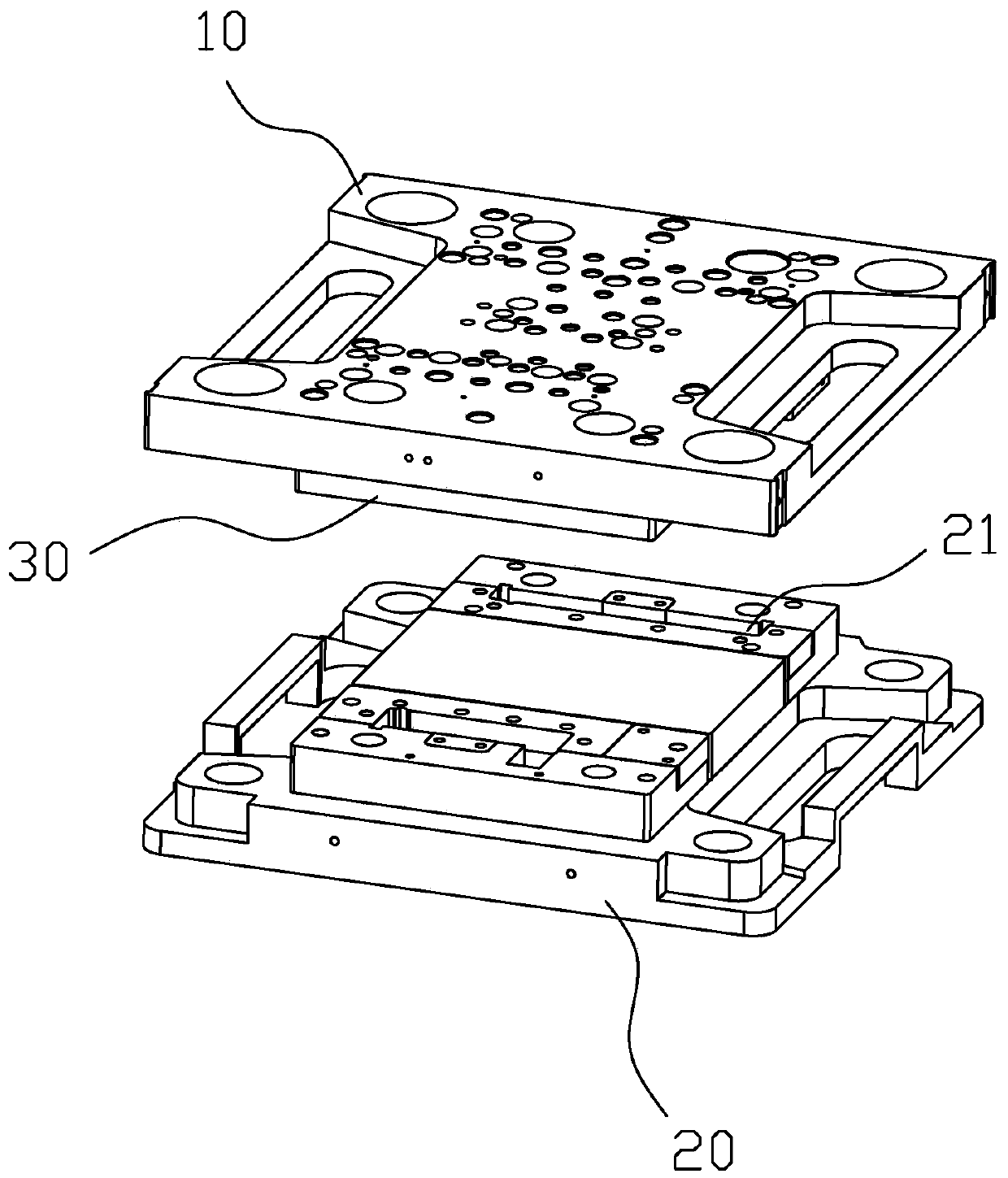

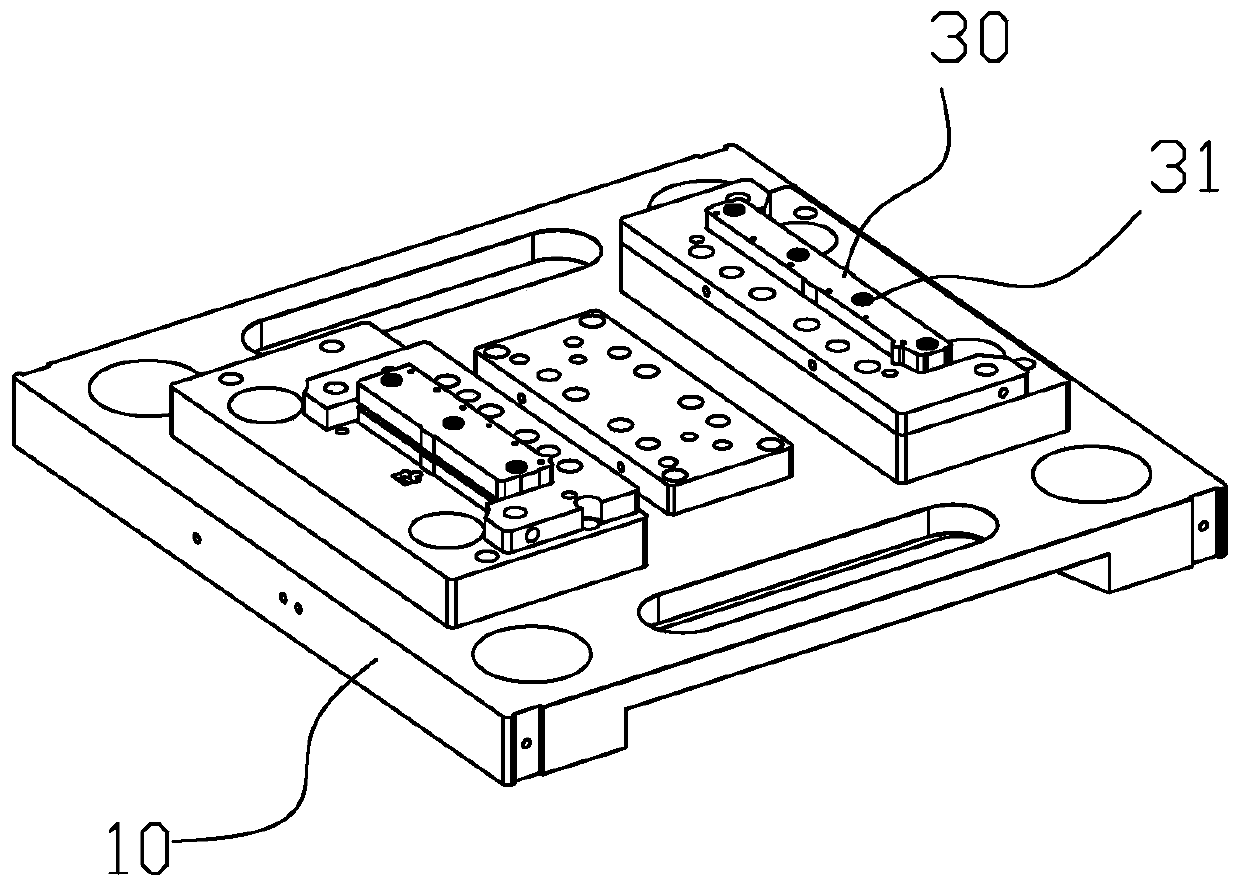

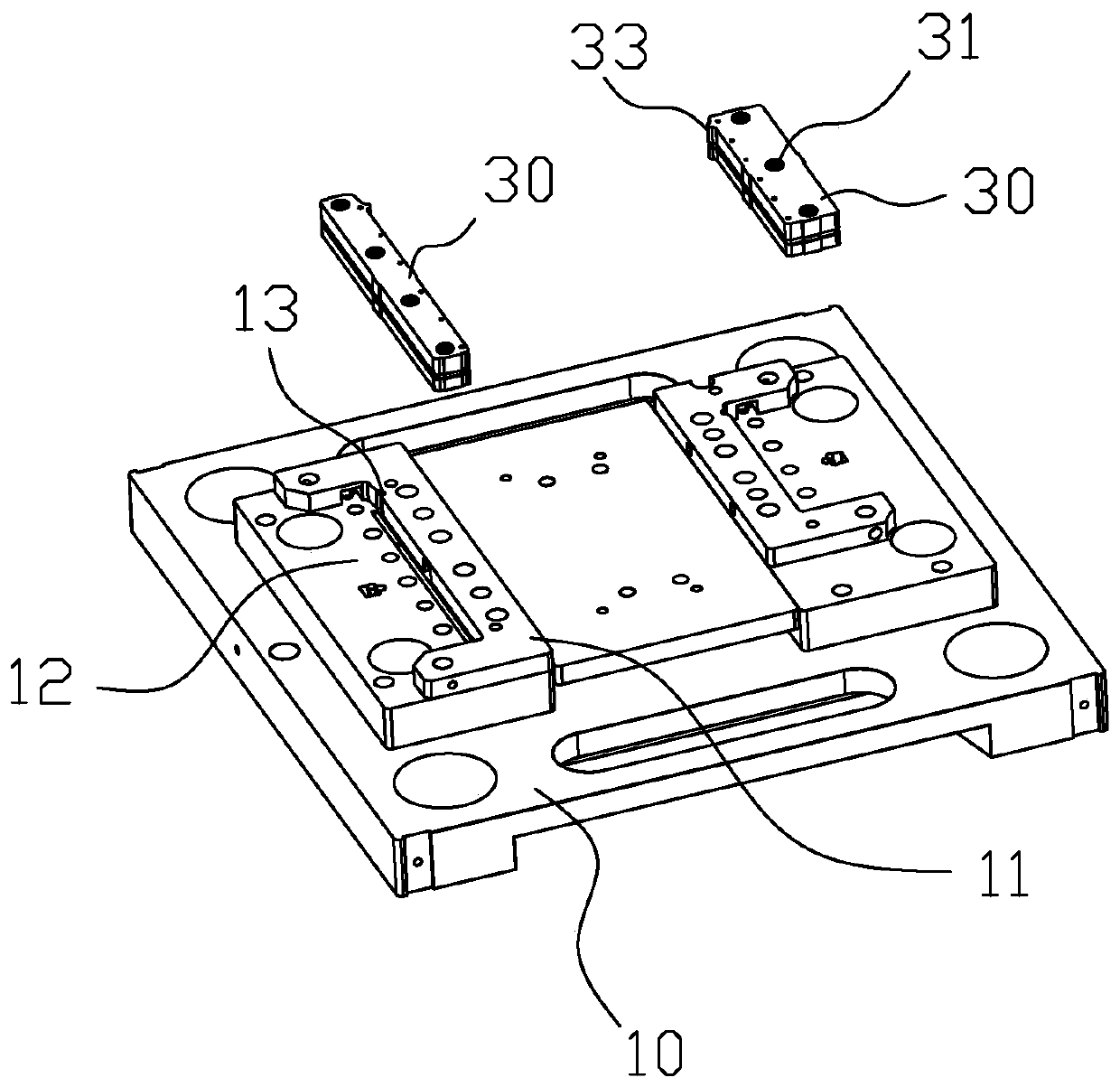

[0026] Such as Figure 1-4 As shown, a ceramic cutting die for positive and negative materials of a lithium battery comprises an upper knife seat 10 and a lower knife seat 20, the lower end of the upper knife seat 10 is provided with a downwardly protruding ceramic punch 30, and the lower knife seat 10 is provided with a ceramic punch 30 protruding downward. The knife seat 20 is provided with a knife edge 21 matched with a ceramic punch 30, and the ceramic punch 30 is provided with an installation through hole 31, and a metal tooth cover 32 is embedded in the installation through hole 31, and the ceramic punch 30 passes through the Bolts and metal braces 32 are threaded and detachably mounted on the upper tool holder 10; the ceramic punch 30 includes the following components by weight: 35-40 parts of iron, 6.5-7.5 parts of nickel, and 6-8 parts of copper , 5.5-7.5 parts of chromium, 3-5 parts of niobium, 1-2 parts of aluminum, 2-3 parts of carbon, 0.45-0.8 parts of silicon, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com