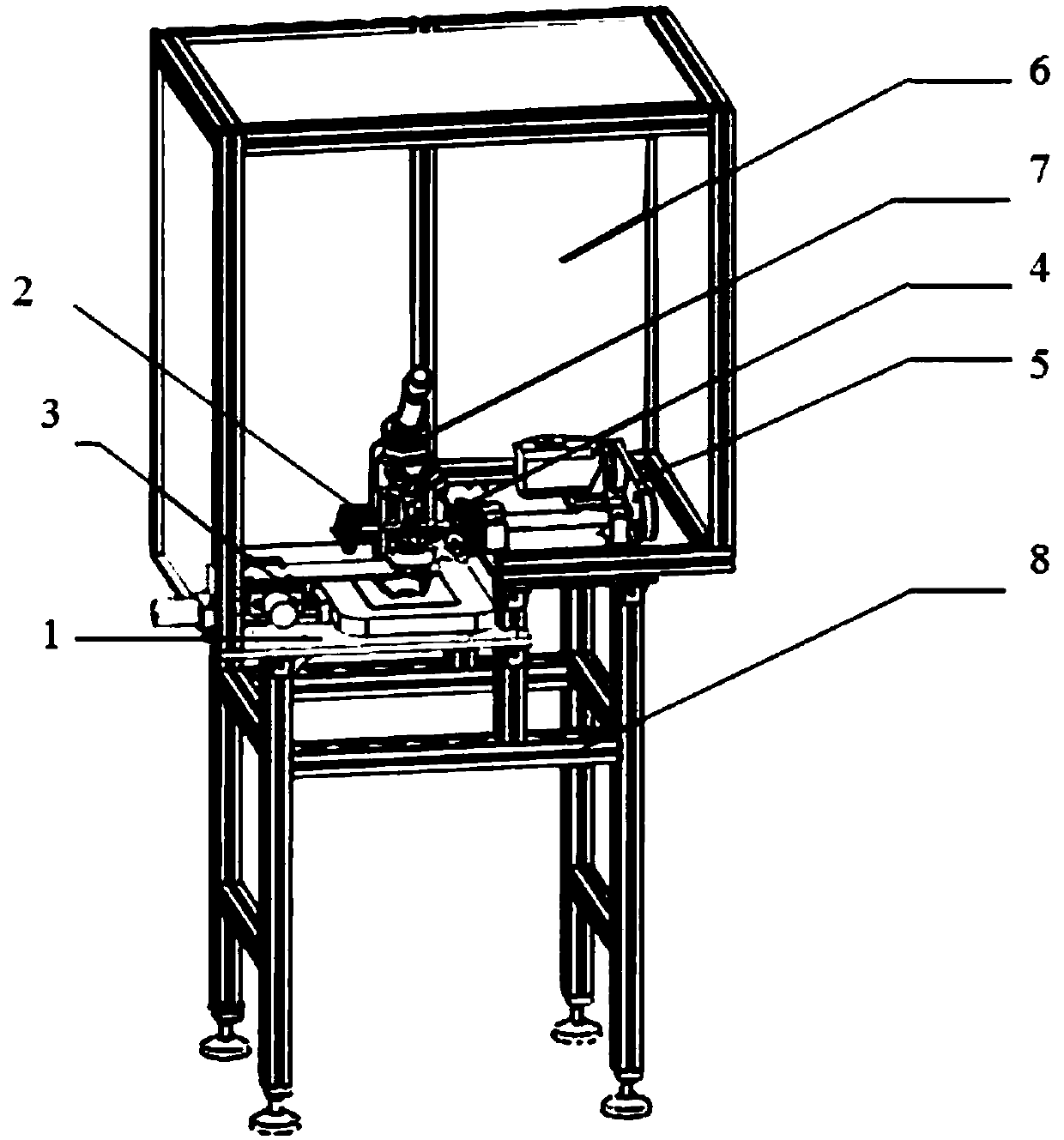

Blade edge grinding machine

A grinding machine and blade technology, which is applied in the direction of grinding frame, grinding machine parts, grinding bed, etc., can solve the complex grinding process of the blade edge, the grinding automation is not easy to realize, and cannot meet the application requirements Demand and other issues, to achieve the effect of quality assurance, high production efficiency, and reduce mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

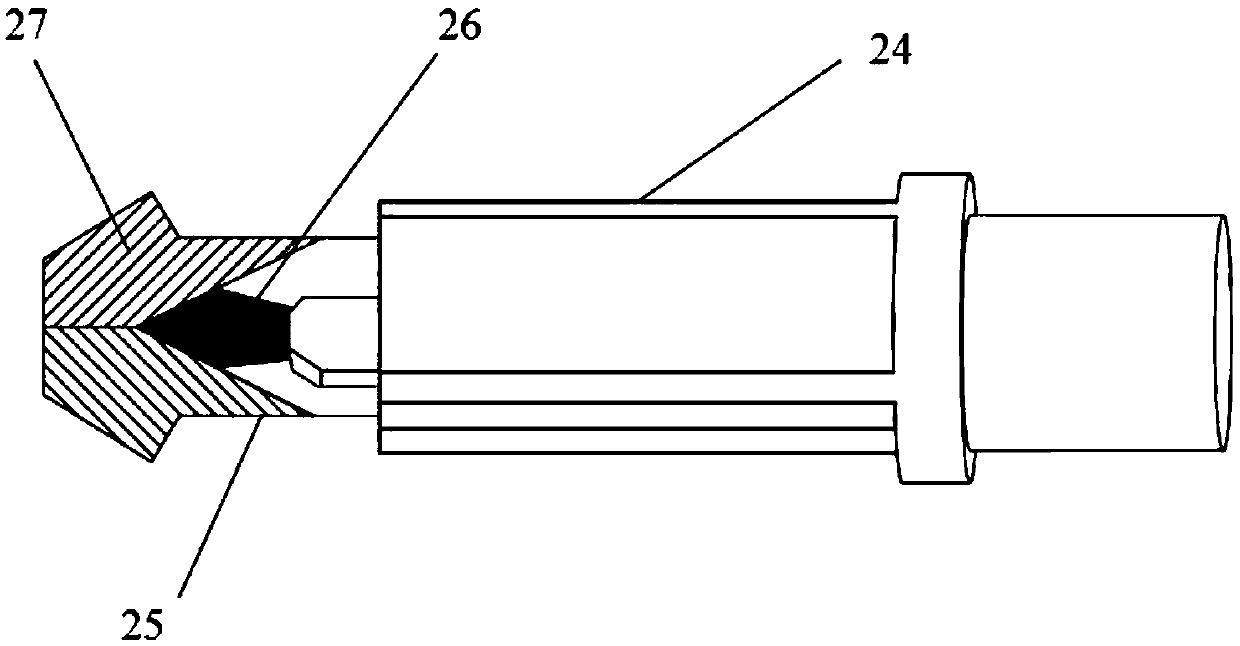

Embodiment 2

[0057] The rest are the same as in Embodiment 1, the difference is that the blade is a single-sided single-side surgical blade, and the grinding device includes a first grinding wheel for grinding the blade edge and a driving device for driving the first grinding wheel to run, and the driving device passes through a rotating shaft Attach the first grinding wheel. In this embodiment, because only one side is sharpened, only one grinding wheel can be set to achieve the purpose of grinding. The first grinding wheel can be set on the left or right side of the position of the blade, depending on the grinding needs. There is no limitation here.

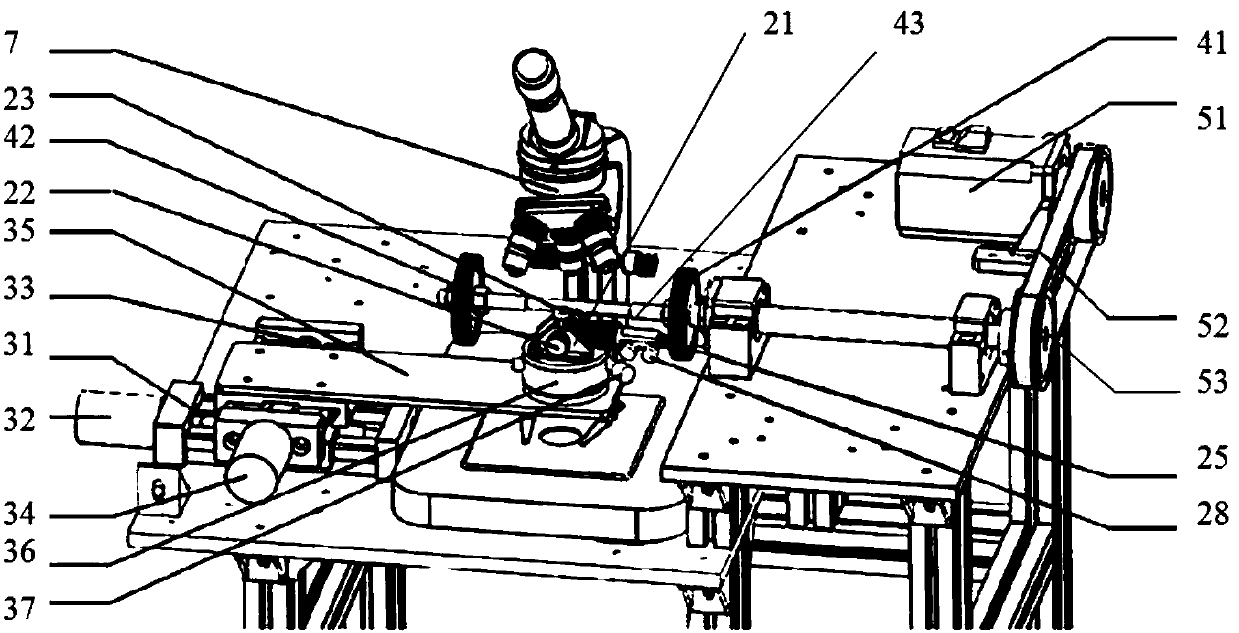

[0058] In summary, the present invention discloses a blade edge grinding machine, in which the blade fixing device and the feed adjustment device have four degrees of freedom (including X-axis movement, Y-axis movement, and Z-axis rotation of the rotary table). , Y-axis turning motion of the tool holder body), which can fully realize the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com