Preparation method of sea urchin-like NaEuTiO4 nanowire

A nanowire, sea urchin-like technology, used in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve safety problems, electroplating and other problems, and achieve the effects of excellent rate performance, long cycle life, and excellent specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In order to achieve the above purpose, the preparation steps of specific amorphous O-doped BN nanosheets are:

[0028] 50 mg of amorphous graphene-like CuB 23 The nanosheets were added to 50 mL of [BMIM]Cl solution to form a suspension.

[0029] 1) Add 2 mmol of Na 2 TiO 3 and 2 mmol EuCl 3 Add to 80mL of 0.2 M sodium tartrate solution, and form a homogeneous suspension under ultrasonic conditions.

[0030] 2) Transfer the suspension to a 100 mL Teflon-lined reactor and keep it at 160 °C for 12 h.

[0031] 3) Use a centrifuge to separate the product sea urchin-like NaEuTiO 4 Nanowires.

[0032] 4) The obtained product was washed three times with deionized water and dried in an oven.

[0033] Urchin-shaped NaEuTiO of the present invention 4 Properties of nanowires:

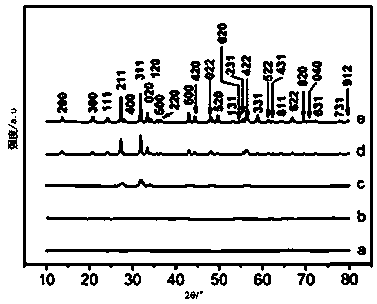

[0034] We will elucidate the synthesis mechanism of this material, from figure 1 a It can be seen that amorphous NaEuTiO was obtained after 0.5h 4 , and the sample consisted of many small irregula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com