Spot welding ultrasonic B scanning automatic detection device and method

An automatic detection device and detection device technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the corrosion damage of parts, be easily affected by humans, and detect accurately Poor performance and other problems, to avoid corrosion and damage, avoid inconsistencies, and save testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

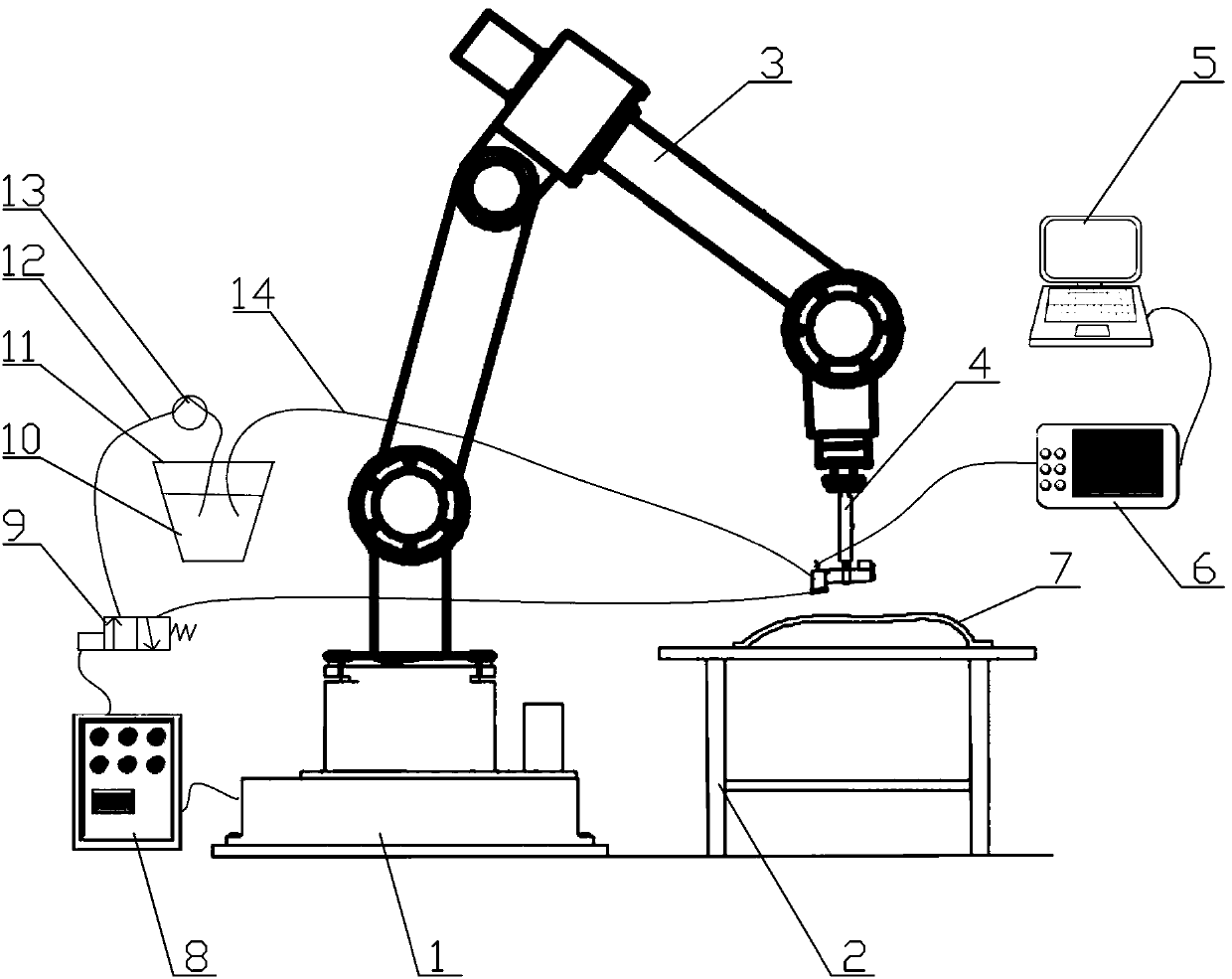

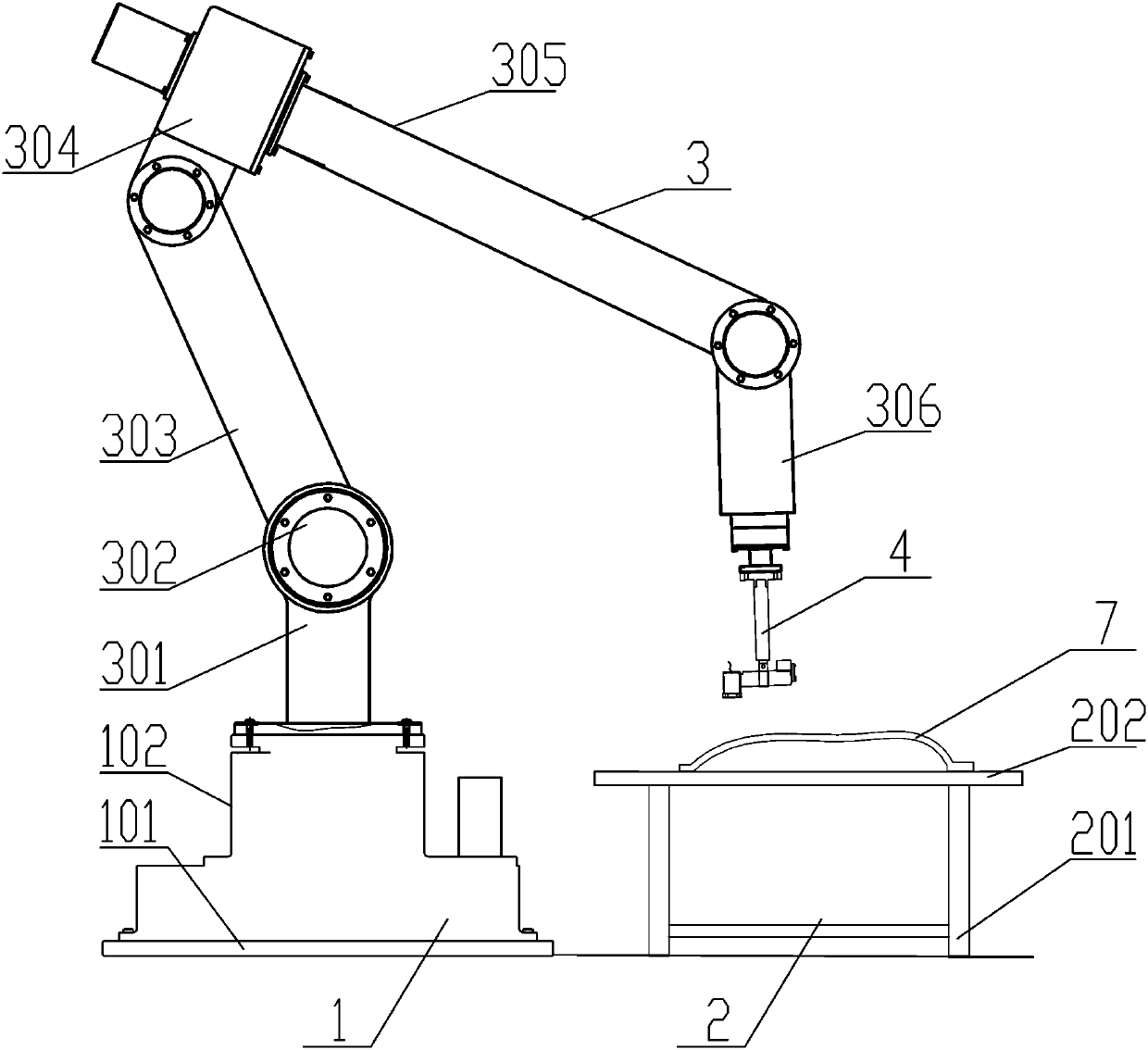

[0038] like Figure 1-4 As shown, a spot welding ultrasonic B-scan automatic detection device, it includes an industrial manipulator 3, the industrial manipulator 3 is installed on the top of the manipulator holder 1, and the head of the industrial manipulator 3 is equipped with an ultrasonic B-scan for welding spots. A detection device 4 for sweep detection, the detection device 4 is located directly above the detection platform 2, the detection device 4 is connected to the ultrasonic detector 6, the ultrasonic detector 6 is connected to the industrial computer 5, and the industrial manipulator 3 is connected to the A controller 8 for controlling the action of the manipulator is connected, and the detection device 4 is connected with a couplant circulation supply system for couplant supply. By adopting the above-mentioned automatic detection device, in the working process, first, the detection device 4 is driven by the industrial manipulator 3 to move along a predetermined tr...

Embodiment 2

[0047] The detection method adopting any one of the spot welding ultrasonic B-scan automatic detection device may further comprise the steps:

[0048] Step1: Fix the body spot welding parts 7 to be detected on the detection platform 2, preset the moving path of the detection probe according to the position of the body spot welding parts 7 to be detected, and input the preset path into the controller 8 of the industrial manipulator 3 ;

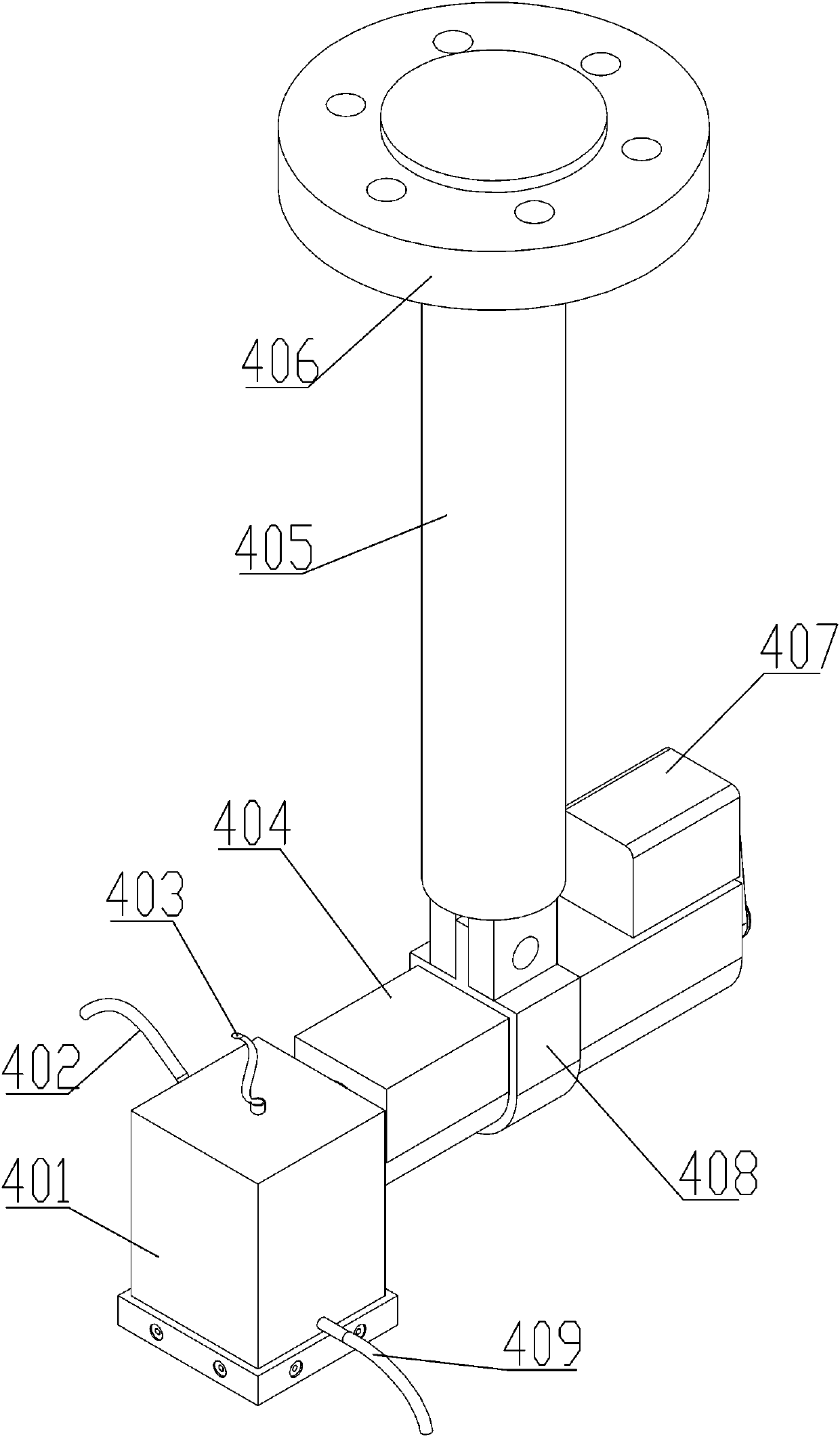

[0049] Step2: Start the industrial manipulator 3, and the industrial manipulator 3 will move the detection device 4 to the position of the first solder spot 417 to be detected according to the preset path, and press the probe cover 401 on the surface of the spot welding part 7 of the vehicle body;

[0050] Step3: Start the couplant circulation supply system, the controller 8 controls the solenoid valve 9 and the water pump 13 to extract the couplant 10, the water inlet pipe 402 starts to inject water into the probe cover 401, and at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com