Damping control method in non-electrolytic capacitance permanent-magnet synchronous-motor air conditioning drive system

A technology of permanent magnet synchronous motor and motor drive system, applied in motor generator control, electronic commutation motor control, motor control and other directions, can solve a large number of mathematical derivation, complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

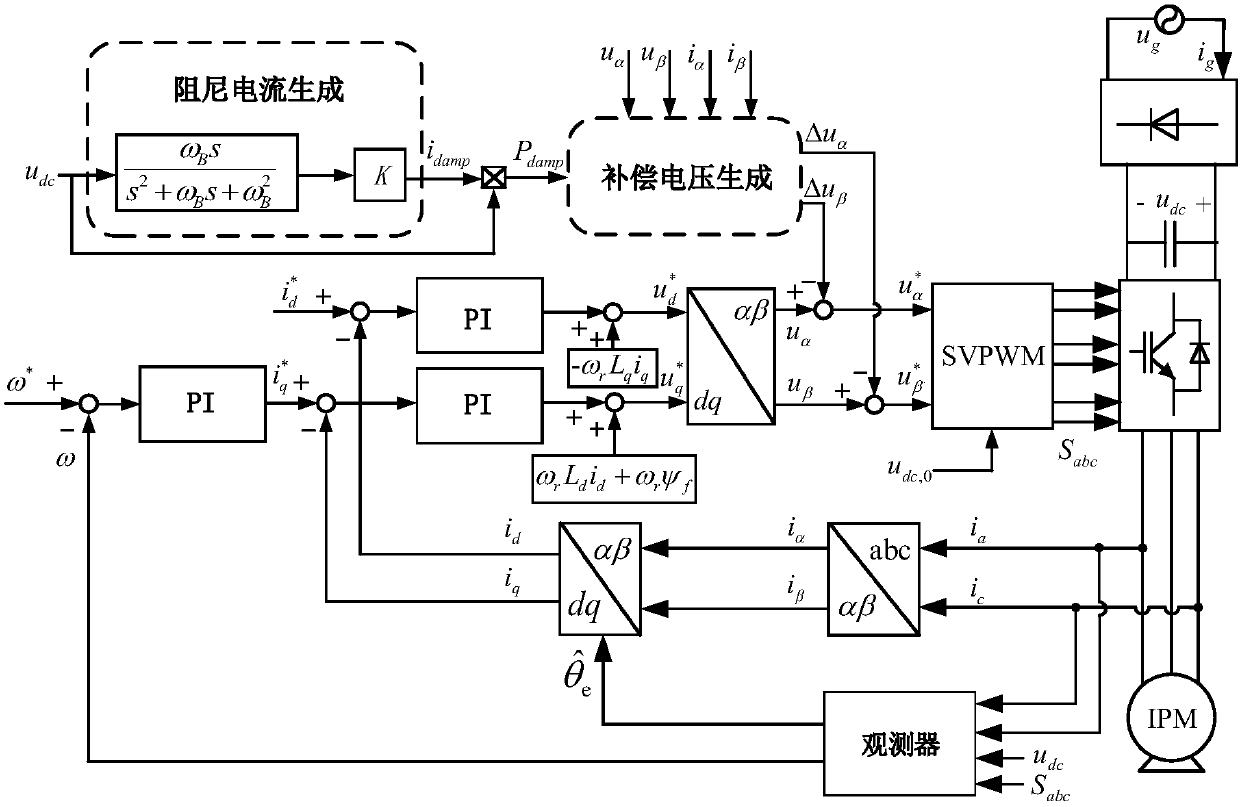

[0080] Specific implementation manner 1: The implementation steps of the damping control method for the resonance phenomenon existing in the electrolytic capacitor permanent magnet synchronous motor drive system are as follows:

[0081] Step 1: The system damping is small. In order to increase the system damping, a damping current can be added in parallel with the inverter current. When the permanent magnet synchronous motor is running, the damping current can be obtained by processing the DC bus voltage with a bandpass filter , And multiply by a coefficient to further adjust the damping characteristics of the system;

[0082] Step 2: Since the frequency of the damping current is often higher than the bandwidth of the inner loop current loop, and the DC bus current is difficult to control, the damping current obtained in step 1 is processed to obtain the equivalent damping power, and the control of the damping power is achieved Damping current control;

[0083] Step 3: Since the dam...

specific Embodiment approach 2

[0085] Embodiment 2: The difference between this embodiment and the above-mentioned embodiment 1 is: the analysis and acquisition of the damping current in parallel with the inverter current in step 1, by passing the DC bus voltage through a The band pass filter is multiplied by a coefficient K to obtain an adjustable damping current to optimize the system operation effect. The specific analysis process is as follows:

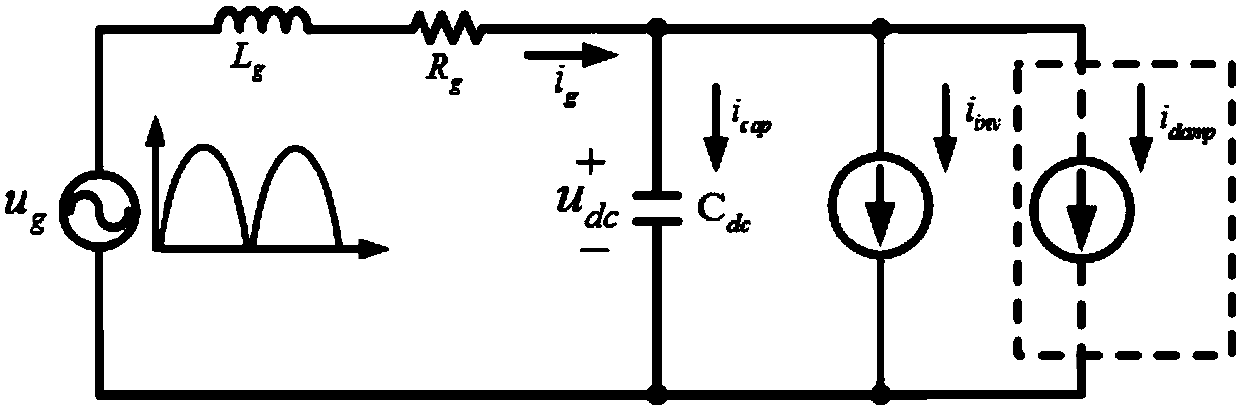

[0086] Such as figure 2 Shown is a simplified circuit diagram of a non-electrolytic capacitor air conditioning drive system obtained after the inverter and the motor are equivalent to a constant current source. In order to improve the damping and stability of the system, the damping current and the inverter current are connected in parallel. The derivation process of the damping current is as follows:

[0087] Input the DC bus voltage into a band-pass filter, and multiply the output of the band-pass filter by a coefficient K to get the damping current. The band pa...

specific Embodiment approach 3

[0099] Embodiment 3: The difference between this embodiment and the second embodiment described above is: the damping current obtained in the embodiment 2 is processed to obtain equivalent damping power, and the damping power is controlled by To realize the control of the damping current;

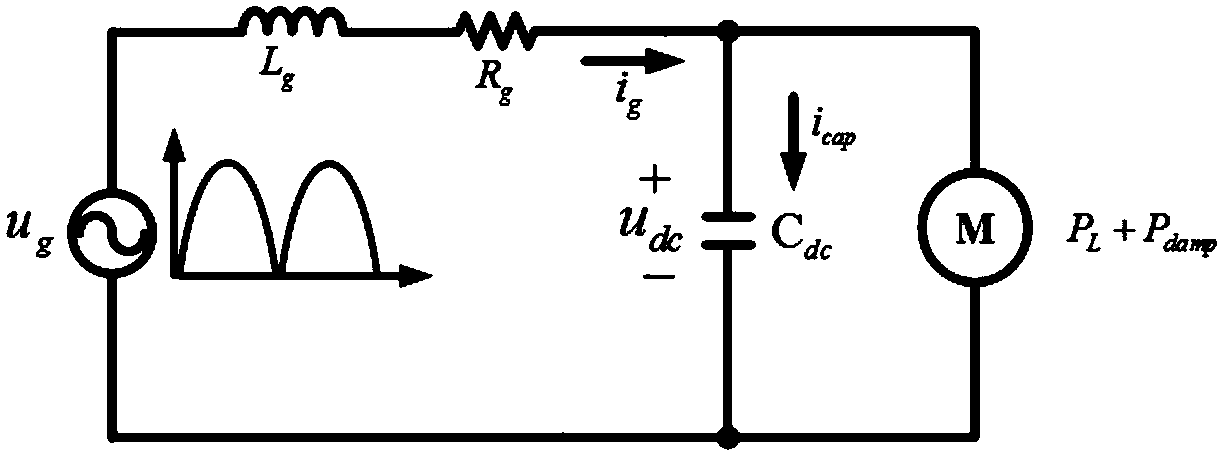

[0100] Because the frequency of the damping current is higher than the frequency of the current loop bandwidth, the damping current cannot be effectively controlled, so the damping power corresponding to the damping current is obtained, and the purpose of improving the damping of the system is achieved by controlling the damping power, thereby eliminating resonance , Stable system. image 3 is true figure 2 Further simplification, such as image 3 As shown, the damping current is represented by damping power, the inverter current is represented by inverter power, and the inverter power is the sum of load power and damping power.

[0101] The expression of damping power is as follows:

[0102] P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com