High-voltage electric field low-temperature plasma cold sterilization system circuit and device

A technology of low-temperature plasma and high-voltage electric field, which is applied in the fields of food electrical treatment, food science, food preservation, etc., can solve the problem that the inverter can only carry the load and cannot drive the capacitive load, so as to avoid the negative resistance effect and facilitate the promotion Reasonable effect of use and structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

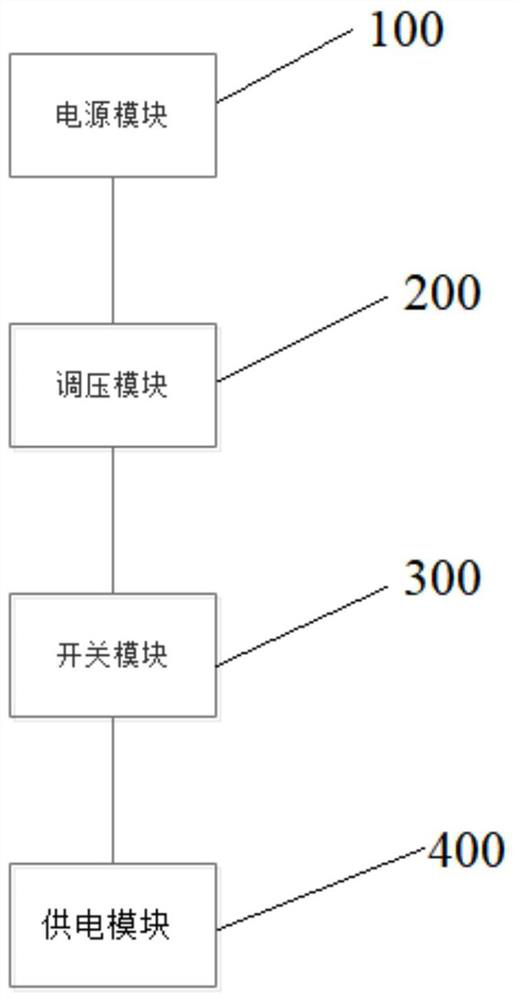

[0044] Please combine figure 2 , figure 2 It is a block diagram of a high-voltage electric field low-temperature plasma cold sterilization system circuit of the present invention.

[0045] A high-voltage electric field low-temperature plasma cold sterilization system circuit, including a power supply module 100 for outputting harmonic current, a voltage regulation module 200 for adjusting load voltage, current and power, and a switch module 300 for adjusting the opening and closing state of the circuit And a transformer power supply module 400 that generates high voltage.

[0046] The power module 100 can be externally connected with a single-phase power input or a three-phase power input, and can output a single-phase voltage. The output voltage of the power module 100 is controllable, and the harmonic component in the output SPWM sinusoidal pulse width modulation wave is effectively suppressed, and the frequency spectrum is expanded, so that the harmonic current entering...

Embodiment 2

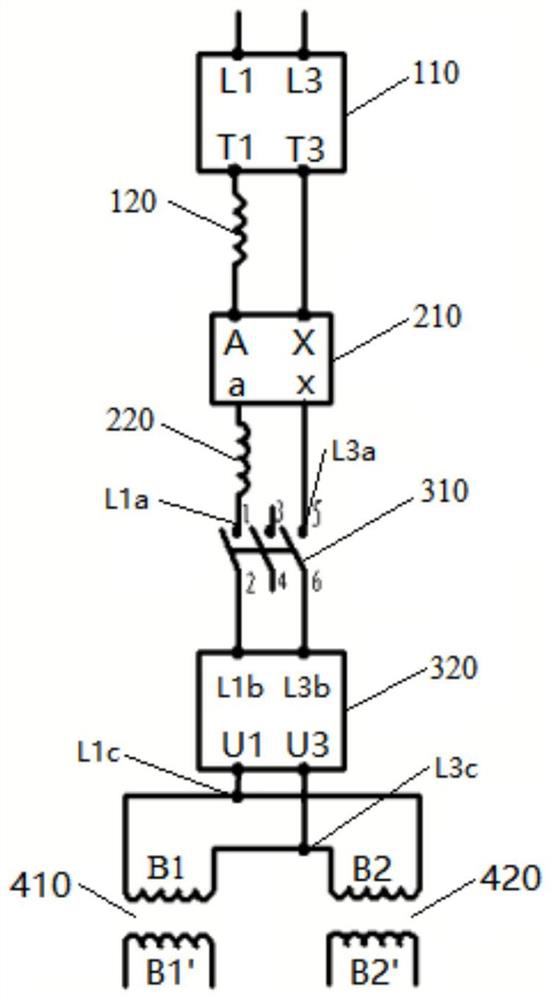

[0057] Please combine image 3 , image 3 It is the circuit diagram of the high-voltage electric field low-temperature plasma cold sterilization system circuit. The high-voltage electric field low-temperature plasma cold sterilization system circuit of the present embodiment, wherein the power module 100 includes a single-phase frequency converter 110, and the single-phase frequency converter 110 includes two input terminals, which are connected with a single-phase power supply (such as AC220). The output terminal T1 of 110 is connected to one end of the first-stage inductor 120 , and the other end of the first-stage inductor 120 is connected to the voltage regulation module 200 ; the output terminal T3 of the single-phase inverter 110 is connected to the voltage regulation module 200 . According to needs, a capacitor can also be connected in parallel between the two output terminals T1 and T3 of the single-phase inverter 110 to enhance the filtering effect.

[0058] recombi...

Embodiment 3

[0064] Please combine Figure 4 , the high-voltage electric field low-temperature plasma cold sterilization system circuit of this embodiment, its basic circuit connection mode is the same as that of Embodiment 2, and the improvements are:

[0065] The power module 100 includes a three-phase inverter 130. The three-phase inverter 130 includes three input terminals connected to a three-phase power supply (such as AC380). The output terminal T1 of the three-phase inverter 130 is connected to one end of the first-stage inductor 120. The other end of the primary inductor 120 is connected to the voltage regulation module 200 ; the output terminal T3 of the three-phase inverter 130 is connected to the voltage regulation module 200 . According to needs, a capacitor can also be connected in parallel between the two output terminals T1 and T3 of the three-phase inverter 130 to enhance the filtering effect. The use of three-phase inverters can be applied to some situations that need to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com