A method of extracting vegetable protein slurry and subjecting it to physical and fermentative treatment

A vegetable protein and slurry technology, applied in the field of vegetable protein processing, can solve the problems of poor flavor, poor water holding capacity and granularity of soybean yogurt, and achieve the effects of excellent texture, increased extraction rate and full flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

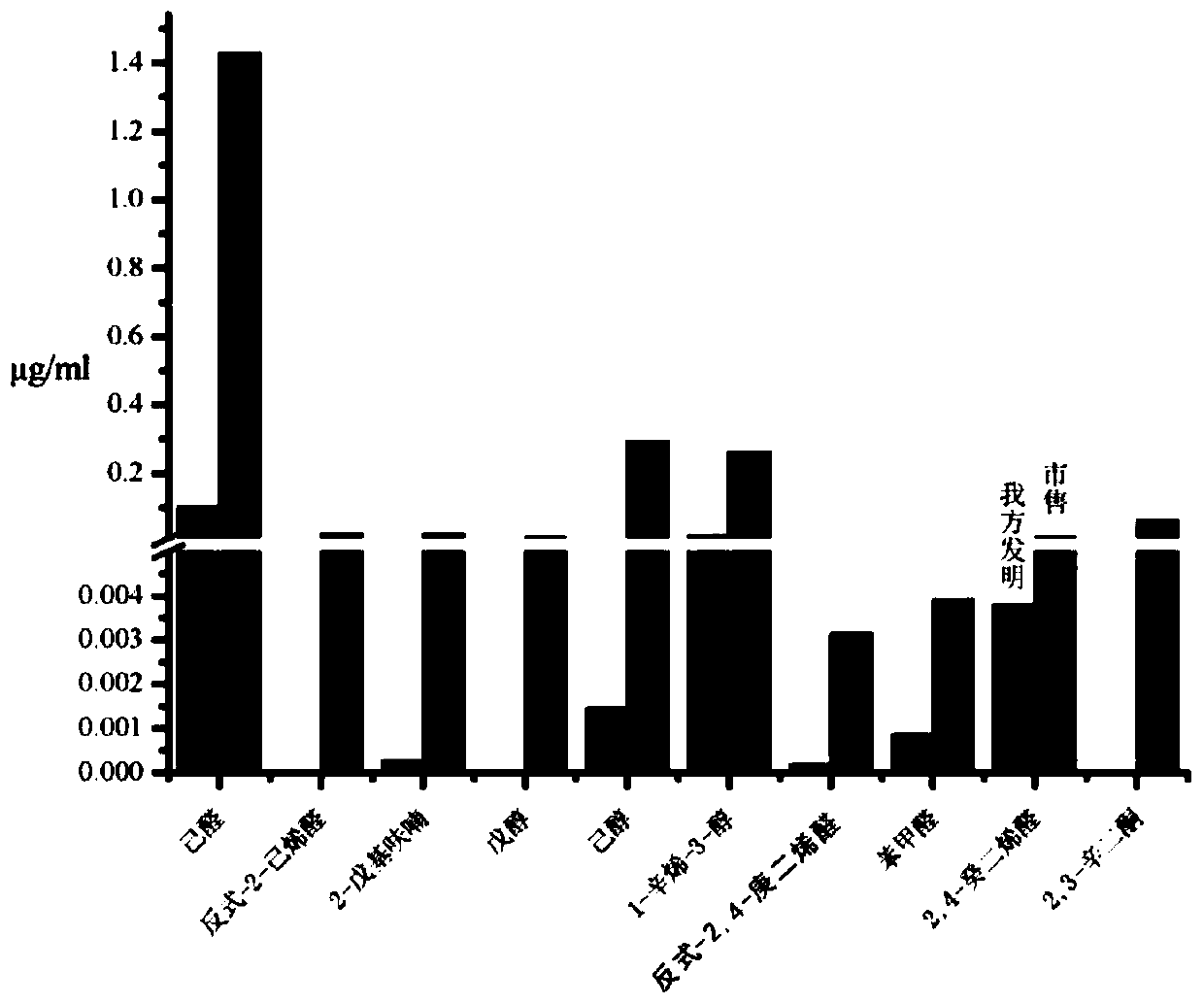

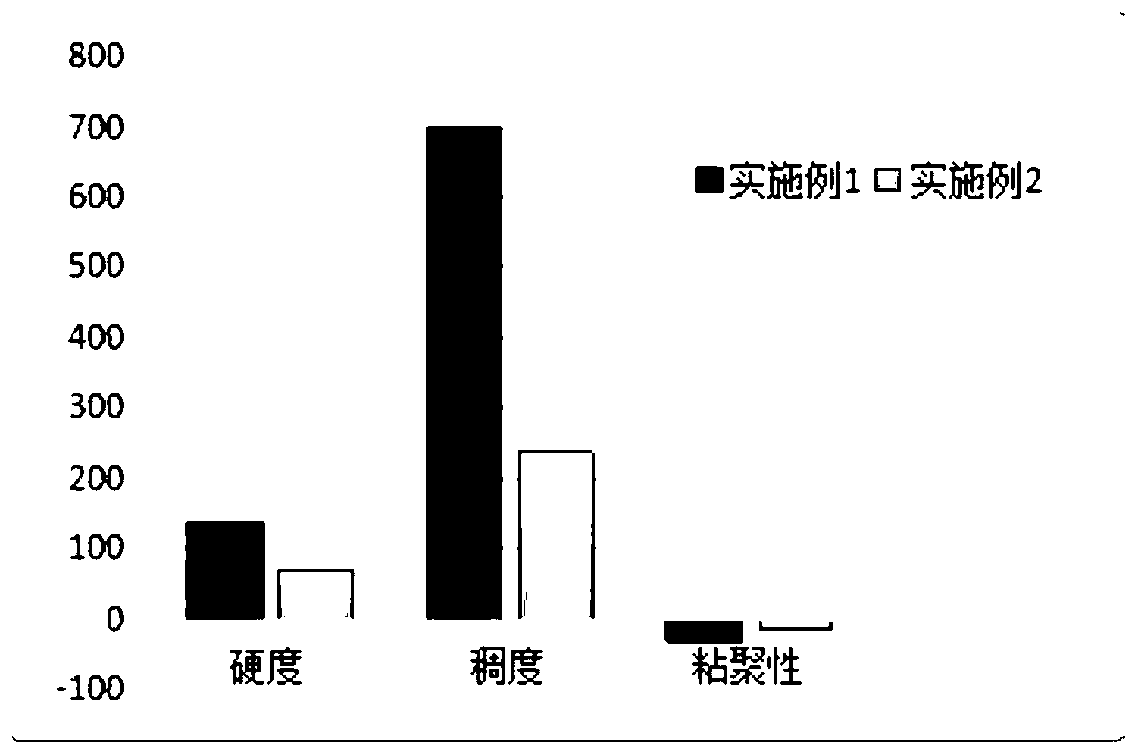

Embodiment 1

[0033] The plant protein raw material used in the present invention is soybeans produced in Northeast China harvested in 2016; soak the soybeans at 25°C for 8 hours after cleaning, and refine the soaked soybeans. The refining parameters are: the feed rate of plant protein raw materials is 140kg / h, the bean feeding rate (converted to dry beans) is 56.90kg / h, the mass flow rate of the milling outflow is 555kg / h, the pressure gauge readings are all greater than 0.1MPa during the refining process, and the refining temperature is 30°C. Slurry is obtained by solid-liquid separation, and heat treatment is performed. The heat treatment conditions are that the product of the heating temperature and the heating time is equal to 3100, the heating temperature is 80-130°C, and the heating time is 25-600s. After the heating is completed, cool to room temperature.

[0034] In order to prepare 100kg of mixed material liquid, take 90kg of soybean milk, 6kg of white granulated sugar, and 4kg of...

Embodiment 2

[0036] The plant protein raw material used in the present invention is soybeans produced in Northeast China harvested in 2016; soak the soybeans at 25°C for 8 hours after cleaning, and refine the soaked soybeans. The refining parameters are: the feed rate of plant protein raw materials is 185kg / h, the bean feeding rate (converted to dry beans) is 56.90kg / h, the mass flow rate of the milling outflow is 555kg / h, the pressure gauge readings are all greater than 0.1MPa during the refining process, and the refining temperature is 30°C. Slurry is obtained by solid-liquid separation, and heat treatment is performed. The heat treatment conditions are that the product of the heating temperature and the heating time is equal to 4800, the heating temperature is 80-130°C, and the heating time is 25-600s. After the heating is completed, cool to room temperature.

[0037] In order to prepare 100kg of mixed material liquid, take 92kg of soybean milk, 6kg of white granulated sugar, and 4kg of...

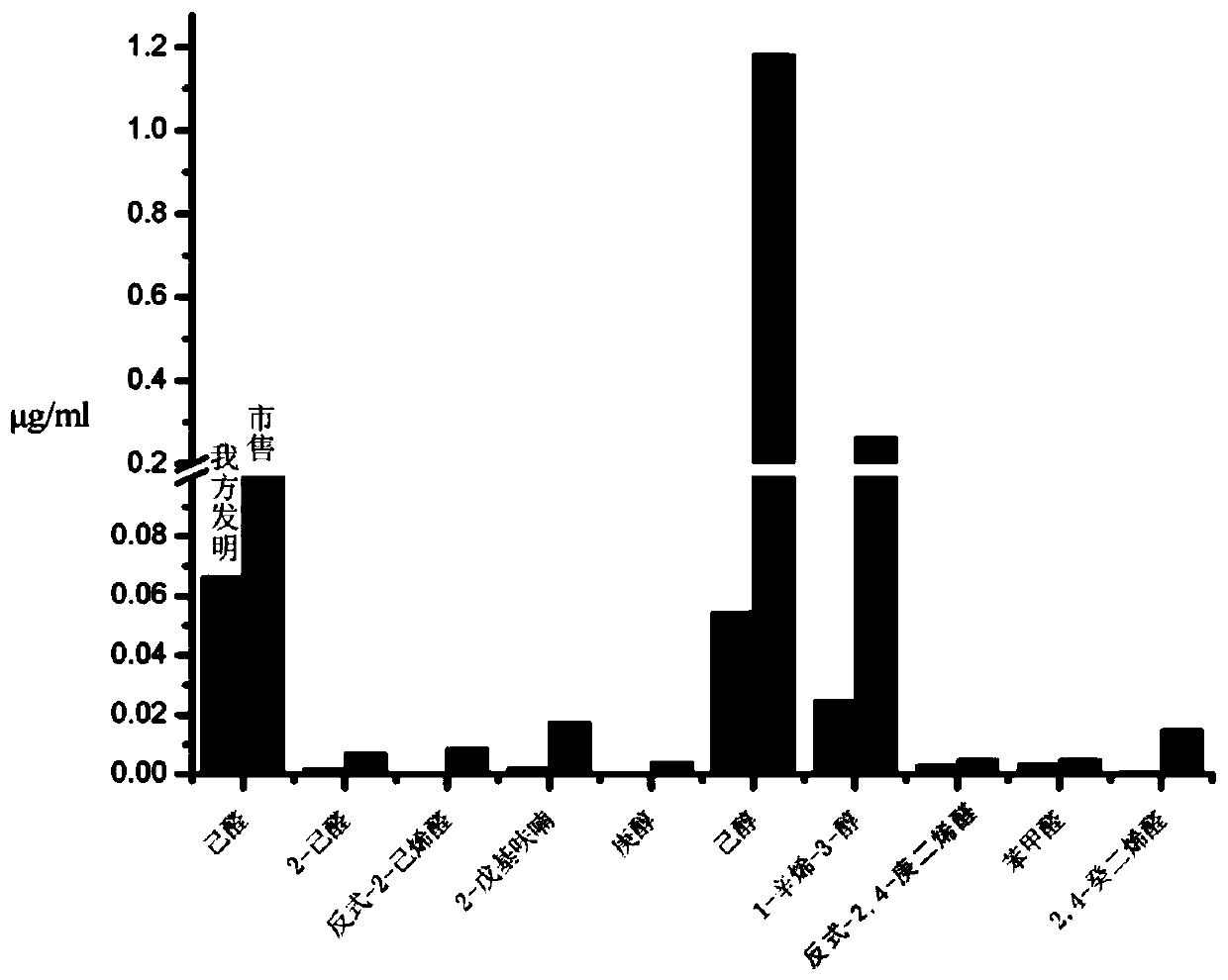

Embodiment 3

[0039] The plant protein raw material used in the present invention is soybeans produced in Northeast China harvested in 2016; soak the soybeans at 25°C for 8 hours after cleaning, and refine the soaked soybeans. The refining parameters are: the feed rate of plant protein raw materials is 140kg / h, the bean feeding rate (converted to dry beans) is 56.90kg / h, the mass flow rate of the milling outflow is 555kg / h, the pressure gauge readings are all greater than 0.1MPa during the refining process, and the refining temperature is 30°C. Slurry is obtained by solid-liquid separation, and heat treatment is performed. The heat treatment conditions are that the product of the heating temperature and the heating time is equal to 4800, the heating temperature is 80-130°C, and the heating time is 25-600s. After the heating is completed, cool to room temperature.

[0040] In order to prepare 100kg of mixed feed liquid, take 88kg of soybean milk, 7kg of white sugar, 2kg of glucose, 1.5kg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com