Soil heavy metal adsorbent and preparation method thereof

A heavy metal and adsorbent technology, applied in chemical instruments and methods, restoration of polluted soil, and other chemical processes, etc., can solve the problems of long repair time, small area of use, soil pollution, etc., to reduce harmful bacteria, The effect of preventing soil compaction and improving soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

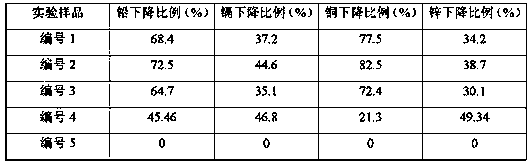

Examples

Embodiment 1

[0015] A soil heavy metal adsorbent, which is composed of the following raw materials in parts by weight: 20 parts of peat, 15 parts of sandstone soil samples, 10 parts of modified attapulgite, 5 parts of sawdust, 6 parts of wheat bran, 3 parts of urea, chitosan 3 parts of sugar, 2 parts of alkali lignin, 40 parts of deionized water.

[0016] Described modified attapulgite is made by following method:

[0017] Dry 12g of ATP at 105°C for 2h, add the dried ATP into 100ml of toluene, stir until uniform, then heat to 60°C, then add 10ml of MPS, stir at constant temperature for 4h, then filter through a vacuum filter, After washing and solid-liquid separation, dry at 105°C for 2 hours to obtain MPS attapulgite, the MPS is methacryloxypropyltrimethoxysilane, grind MPS attapulgite to 200 mesh, take 2g of attapulgite after grinding Add MPS attapulgite in 100ml toluene and stir evenly, then add 0.5g acrylic acid and azobisisobutyronitrile successively, the quality of described azobis...

Embodiment 2

[0024] A soil heavy metal adsorbent, which is composed of the following raw materials in parts by weight: 30 parts of peat, 22 parts of sandstone soil samples, 15 parts of modified attapulgite, 7 parts of sawdust, 8 parts of wheat bran, 4 parts of urea, chitosan 4 parts of sugar, 3 parts of alkali lignin, 65 parts of deionized water.

[0025] Described modified attapulgite is made by following method:

[0026] Dry 12.5g of ATP at 106°C for 2.5h, add the dried ATP into 102ml of toluene, stir until uniform, then heat to 61°C, then add 11ml of MPS, stir at constant temperature for 4.5h, and then pass through a vacuum filter After filtering, washing, and solid-liquid separation, dry at 107°C for 2.53 hours to obtain MPS attapulgite. The MPS is methacryloxypropyltrimethoxysilane, and the MPS attapulgite is ground to 225 mesh. Take 2.5g of ground MPS attapulgite and add it to 102ml of toluene and stir evenly, then add 0.6g of acrylic acid and azobisisobutyronitrile in sequence, the...

Embodiment 3

[0033] A soil heavy metal adsorbent, which is composed of the following raw materials in parts by weight: 40 parts of peat, 30 parts of sandstone soil samples, 20 parts of modified attapulgite, 8 parts of sawdust, 10 parts of wheat bran, 5 parts of urea, chitosan 5 parts of sugar, 4 parts of alkali lignin, 90 parts of deionized water.

[0034] Described modified attapulgite is made by following method:

[0035] Dry 13g of ATP at 108°C for 3h, add the dried ATP into 105ml of toluene, stir until uniform, then heat to 62°C, then add 12ml of MPS, stir at constant temperature for 5h, then filter through a vacuum filter, After washing and solid-liquid separation, dry at 110°C for 3 hours to obtain MPS attapulgite. The MPS is methacryloxypropyltrimethoxysilane. Grind the MPS attapulgite to 250 mesh, take 3g of attapulgite after grinding Add MPS attapulgite in 105ml toluene and stir evenly, then add 0.7g acrylic acid and azobisisobutyronitrile successively, the quality of described a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com