Metal member with modularized composite wear and corrosion resistant layer and preparation method thereof

A technology of wear-resistant layer and metal components, which is applied in the field of materials, can solve the problems of the influence of the wear-resistant layer on the degree of mold adaptation, the difficulty of mold making, and the difficulty of increasing the forming of the wear-resistant layer, so as to ensure rigid high-strength contact, Reduce the difficulty of production and eliminate the effect of curing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

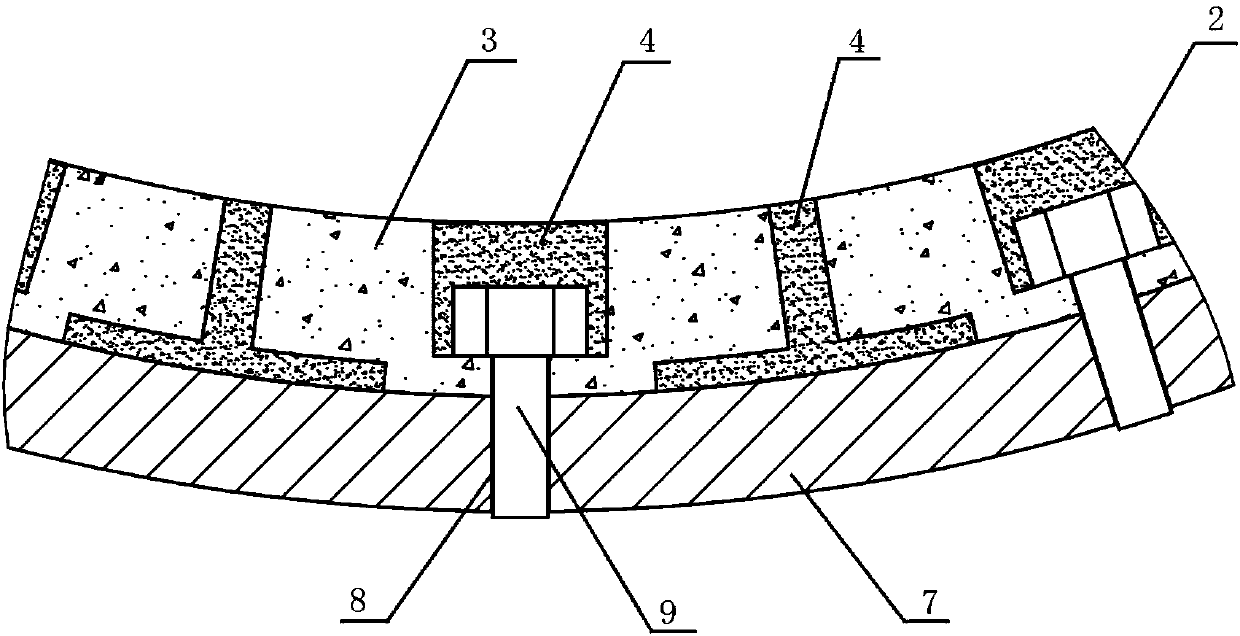

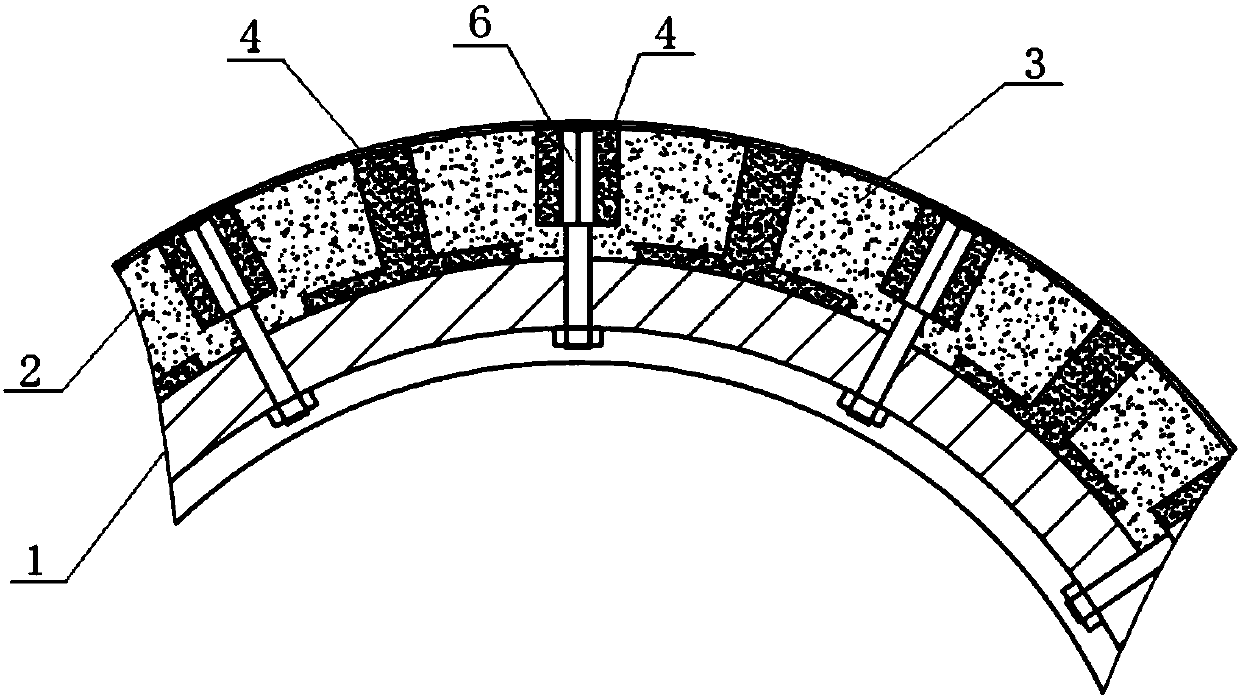

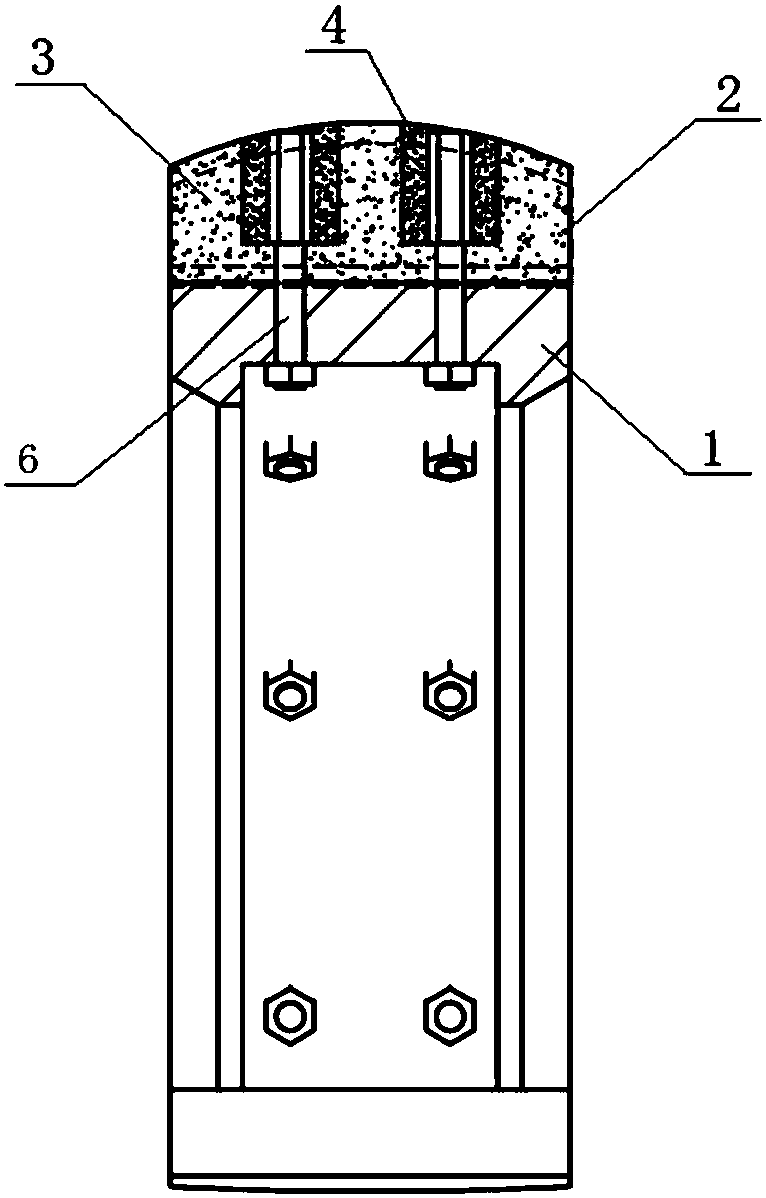

[0045] Such as figure 2 and image 3 As shown, the present embodiment is a manufacturing method of a grinding roller 1 equipped with an abrasion-resistant layer 2, and the method comprises the following steps:

[0046] 1) Make wear-resistant modules;

[0047] 1.1) Design and manufacture the mold of the wear-resistant module 3 according to the structural requirements of the grinding roller 1;

[0048] 1.2) Three kinds of silicon carbide particles with different particle sizes are mixed as wear-resistant particles and filled into the mold; wherein, the particle size of the large particles is greater than 700 microns and less than or equal to 2000 microns, accounting for 40% of the total mass of the particles; The particle size of medium particles is greater than 150 microns and less than or equal to 700 microns, accounting for 55% of the total mass of particles; the particle size of small particles is greater than 50 microns and less than or equal to 150 microns, accounting f...

Embodiment 2

[0062] Such as Figure 4 As shown, the present embodiment is a manufacturing method of a pump core 5 with an abrasion-resistant layer 2 added, and the method includes the following steps:

[0063] 1) Make wear-resistant modules;

[0064] 1.1) Design and manufacture the mold of the wear-resistant module 3 according to the structural requirements of the pump core 5;

[0065] 1.2) Three kinds of alumina ceramic particles with different particle sizes are mixed as wear-resistant particles and filled into the mold; wherein, the particle size of the large particles is greater than 700 microns and less than or equal to 2000 microns, accounting for 25% of the total mass of the particles ; The particle size of medium particles is greater than 150 microns and less than or equal to 700 microns, accounting for 35% of the total mass of particles; the particle size of small particles is greater than 50 microns and less than or equal to 150 microns, accounting for 40% of the total mass of p...

Embodiment 3

[0079] This embodiment is a method for manufacturing a pipeline with an anti-corrosion layer on the inner wall. The method includes the following steps:

[0080] 1) Make wear-resistant modules;

[0081] 1.1) Design and manufacture the mold of the wear-resistant module according to the structural requirements of the pipeline;

[0082] 1.2) Fill the mold with wear-resistant particles; the wear-resistant particles in this embodiment are silicon carbide particles with a particle size distribution greater than 150 microns and less than or equal to 700 microns and a particle size distribution greater than 700 microns and less than or equal to The 2000 micron alumina ceramic particles are mixed according to the mass ratio of 1:2.

[0083] 1.3) In a vacuum environment, inject the phenolic resin mixed with the curing agent into the mold and solidify to form an abrasion-resistant module with mounting holes;

[0084] 2) Make pipelines and install wear-resistant modules;

[0085] 2.1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com