Preparation method for copper/cuprous oxide cladded paraffin microcapsule photothermal conversion phase-change energy-storage composite material

A technology of paraffin microcapsules and cuprous oxide is applied in the field of energy storage materials to achieve the effects of simple preparation method, improved heat transmission speed and excellent light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Mix sliced paraffin (0.4g) with oleylamine (0.4g), and stir continuously for 5 minutes at 65°C at a stirring speed of 600 rpm to obtain a uniform oil phase liquid (0.8g).

[0042] (2) Dissolve copper formate tetrahydrate (0.8g) and glucose (1.6g) in deionized water (40g), stir manually for 10min to form a uniform solution, and then add dropwise to the oil phase in step 1, Stirring was continued at 65° C. at a stirring speed of 600 rpm for 5 minutes to gradually form an emulsion to obtain a reaction mixture (43.2 g).

[0043] (3) Pour the reaction mixture obtained in step (2) into the polytetrafluoroethylene liner of a 100ml high-pressure reactor, put it in a constant temperature oven at 120°C, and react for 6 hours. After the reaction, the emulsion is centrifuged and deionized. After washing with water and drying at 50° C. for 12 hours, the copper / cuprous oxide-coated paraffin phase-change energy storage microcapsules can be obtained.

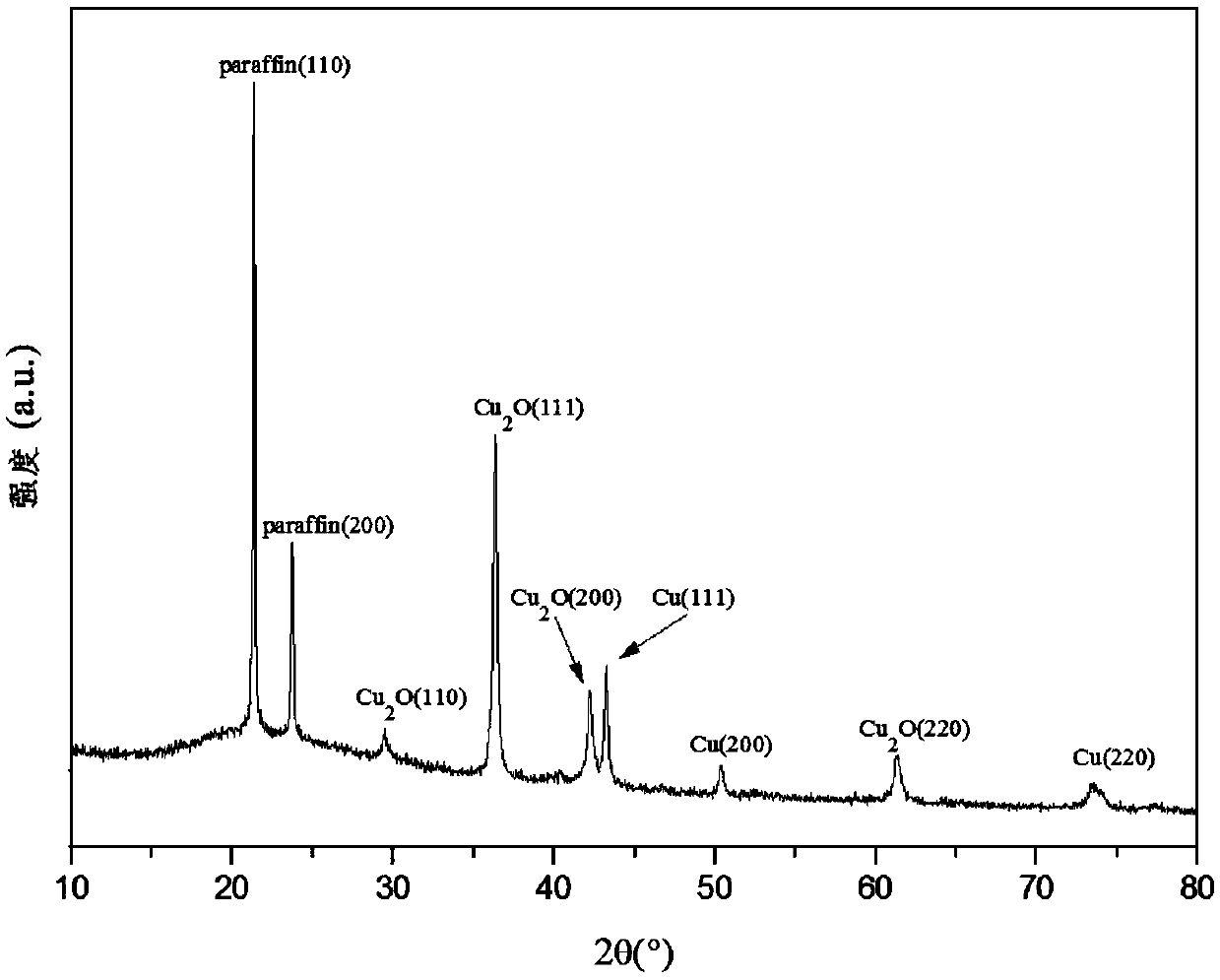

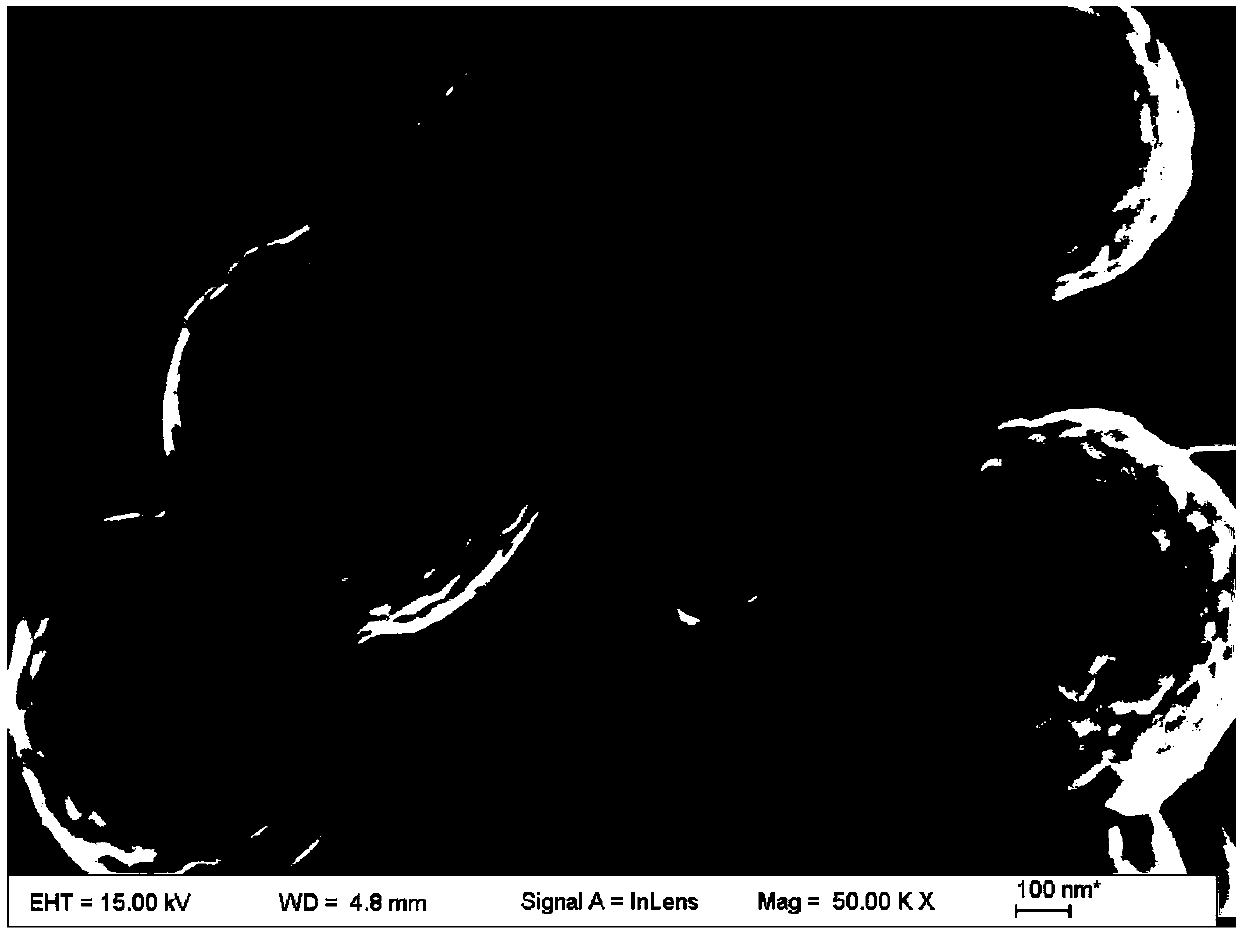

[0044] figure 1 It is the...

Embodiment 2

[0049] (1) Mix sliced paraffin (3.0g) with oleylamine (1.6g), and stir continuously for 20 minutes at 85°C and a stirring speed of 800 rpm to obtain a uniform oil phase liquid (4.6g).

[0050] (2) Dissolve copper formate tetrahydrate (3.0g) and glucose (6.0g) in deionized water (80g), stir manually for 10min to form a uniform solution, and then add dropwise to the oil phase in step 1, Stirring was continued for 30 minutes at 85° C. at a stirring speed of 1000 rpm to gradually form an emulsion to obtain a reaction mixture (93.6 g).

[0051] (3) Pour the emulsion into the polytetrafluoroethylene liner of the high-pressure reactor, put it in a constant temperature oven at 150°C, and react for 24 hours. After the reaction, the emulsion is centrifuged, washed with deionized water, and dried at 50°C for 12 hours. , the copper / cuprous oxide-coated paraffin phase-change energy storage microcapsules can be obtained.

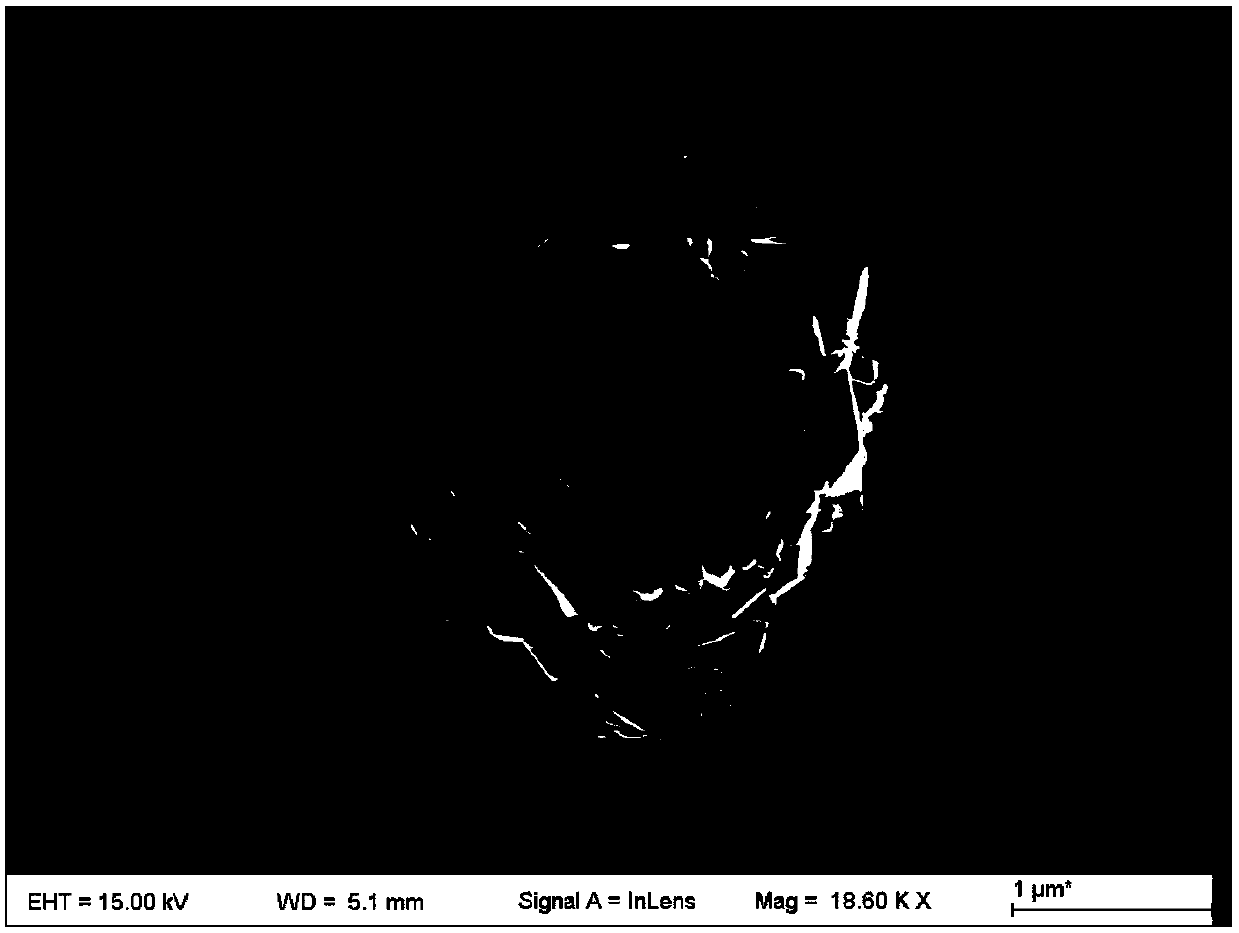

[0052] image 3 It is the SEM photo of the product obtained in t...

Embodiment 3

[0055] (1) Mix sliced paraffin (0.8g) with oleylamine (0.8g), and stir continuously for 10 minutes at 75°C at a stirring speed of 1000 rpm to obtain a uniform oil phase liquid (1.6g).

[0056] (2) Dissolve copper formate tetrahydrate (1.6g) and glucose (3.2g) in deionized water (64g), stir manually for 10min to form a uniform solution, and then add it dropwise to the oil phase in step 1, Stirring was continued for 30 minutes at 75° C. at a stirring speed of 1000 rpm to gradually form an emulsion to obtain a reaction mixture (70.4 g).

[0057] (3) Pour the emulsion into the polytetrafluoroethylene liner of the high-pressure reactor, put it in a constant temperature oven at 120°C, and react for 12 hours. After the reaction, the emulsion is centrifuged, washed with deionized water, and dried at 50°C for 12 hours. , the copper / cuprous oxide-coated paraffin phase-change energy storage microcapsules can be obtained.

[0058] Table 1 shows the DSC test results of paraffin wax and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com