Aluminum alloy for vehicle body and preparation method thereof

An aluminum alloy and body technology, which is applied in the field of aluminum alloy composition design and heat treatment for body panels, can solve the problems of improving the hardening ability of the stamping and forming ability of the downstream automobile factory, reducing the hardening ability of the paint baking process, and restricting the application of the body, etc. Achieve low temperature rapid strengthening, improve wear and corrosion resistance, and high room temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing an aluminum alloy for a vehicle body, comprising:

[0035] S1. Adjustment of content and ratio of main alloying elements, addition of microalloying elements.

[0036] According to the calculation and analysis of thermodynamic balance, the alloy composition is designed, the aluminum alloy raw material is smelted into a billet, and the sample is analyzed to control the chemical composition of the billet. The main alloying elements include: Mg: 0.7-1.2%, Si: 0.4-0.8%, Cu: 0.2- 0.9%, Zn: 1.5-3.0%, Fe: ≤0.5%, microalloying elements include: Sn: 0.02-0.06%, In: 0.02-0.06%, matrix elements include Al: balance.

[0037] S2. Homogenization treatment.

[0038] The homogenization treatment in this embodiment is a two-stage homogenization treatment. Specifically, the two-stage homogenization treatment is carried out in a resistance furnace, and the billet is kept at a primary heating temperature of 480-520 ° C for 2-4 hours to realize the solidification proces...

Embodiment 1

[0056] This embodiment provides a method for preparing an aluminum alloy for a vehicle body, which includes:

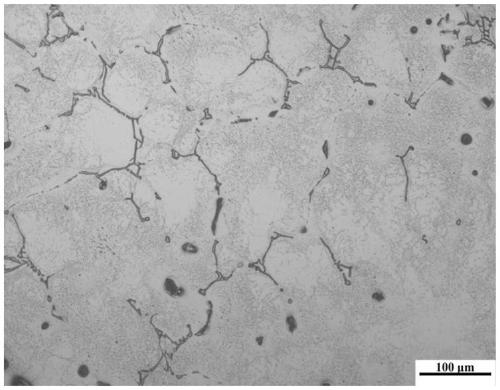

[0057] (1) According to the calculation and analysis of thermodynamic equilibrium, the alloy composition is designed, the aluminum alloy raw material is smelted into a billet, and the sample is analyzed to control the chemical composition of the billet. The main alloying elements include: Mg: 0.8%, Si: 0.6%, Cu : 0.25%, Zn: 1.6%, Fe: 0.45%, Sn: 0.03, In: 0.03, and the balance of Al. Its as-cast structure is as figure 1 shown by figure 1 It can be seen that the grain boundary network AlFeSi crystal phase exists in the as-cast structure.

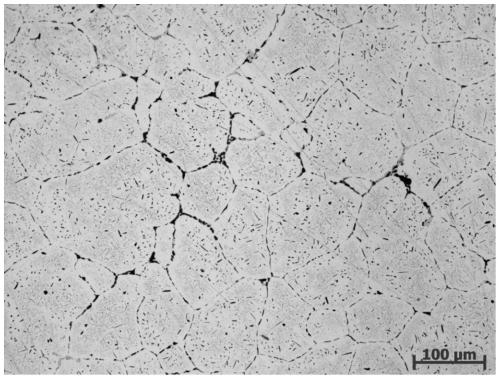

[0058] (2) Heat the billet at a heating rate of 2°C / s to the primary heating temperature of 510°C for 3 hours, and at a heating rate of 11°C / s to the secondary heating temperature of 570°C for 6 hours; after 510°C / 3h- After double-stage homogenization treatment at 570℃ / 6h, its metallographic structure is as follows: figure 2 As s...

Embodiment 2

[0063] This example provides a method for preparing an aluminum alloy for vehicle body, the design alloy composition Mg: 0.9%, Si: 0.8%, Cu: 0.3%, Zn: 1.8%, Fe: 0.3%, Sn: 0.025, In: 0.04 , and the balance of Al. Thermal processing and heat treatment process are all consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com