A kind of water-in-oil-in-water emulsifier and its application and application method

A water-in-oil-in-water emulsifier technology, which is applied in pharmaceutical formulations, antiviral agents, medical preparations containing active ingredients, etc., to achieve high commercial value, low price, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 Emulsifier X1

[0040] Emulsifier X1 includes: mineral oil 88 grams; polyethylene glycol 400 monooleate 9 grams; mannitol monooleate 3 grams.

[0041] Its method of use includes the following steps:

[0042] 1) Heat emulsifier X1 to 30°C;

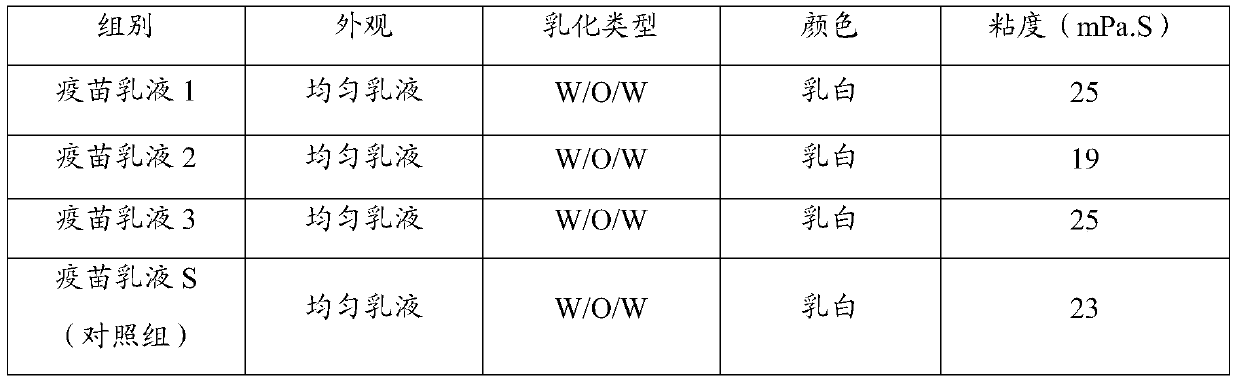

[0043] 2) Take 130 grams of heated emulsifier X and put it into a 200mL beaker, and add another 30 grams of antigen (inactivated porcine foot-and-mouth disease virus) aqueous solution at 35°C to the beaker, and place the beaker under a mechanical stirrer after adding , keep stirring at a speed of 200 rpm for 15 minutes to make the emulsion uniform, and obtain the self-made vaccine emulsion 1.

[0044] The use of the emulsifier X1 is as an adjuvant for porcine foot-and-mouth disease vaccine.

Embodiment 2

[0045] Embodiment 2 Emulsifier X2

[0046] Emulsifier X2 includes: 85 grams of mineral oil; 9 grams of polyethylene glycol 400 monooleate; 3 grams of mannitol monooleate, and 3 grams of fatty alcohol polyoxyethylene ether.

[0047] Its method of use includes the following steps:

[0048] 1) Heat emulsifier X2 to 35°C;

[0049]2) Put 45 grams of heated emulsifier X2 into a 200mL beaker, and add another 30 grams of antigen (inactivated porcine foot-and-mouth disease virus) aqueous solution at 15°C to the beaker, and place the beaker on a mechanical stirrer after adding Keep stirring at a speed of 250 rpm for 15 minutes to make the emulsion uniform, and obtain the self-made vaccine emulsion 2.

[0050] The use of the emulsifier X2 is as an adjuvant for porcine foot-and-mouth disease vaccine.

Embodiment 3

[0051] Embodiment 3 Emulsifier X3

[0052] Emulsifier X3 includes: 82 grams of mineral oil; 9 grams of polyethylene glycol 400 monooleate; 3 grams of mannitol monooleate, and 3 grams of fatty alcohol polyoxyethylene ether.

[0053] Its method of use includes the following steps:

[0054] 1) Heat emulsifier X3 to 30°C;

[0055] 2) Put 40 grams of the heated emulsifier X3 into a 200mL beaker, and add another 30 grams of an aqueous solution of antigen (inactivated porcine foot-and-mouth disease virus) at 20°C to the beaker, and place the beaker on a mechanical stirrer after adding Keep stirring at a speed of 225 rpm for 12 minutes to make the emulsion uniform, and obtain the self-made vaccine emulsion 3.

[0056] The use of the emulsifier X3 is as an adjuvant for porcine foot-and-mouth disease vaccine.

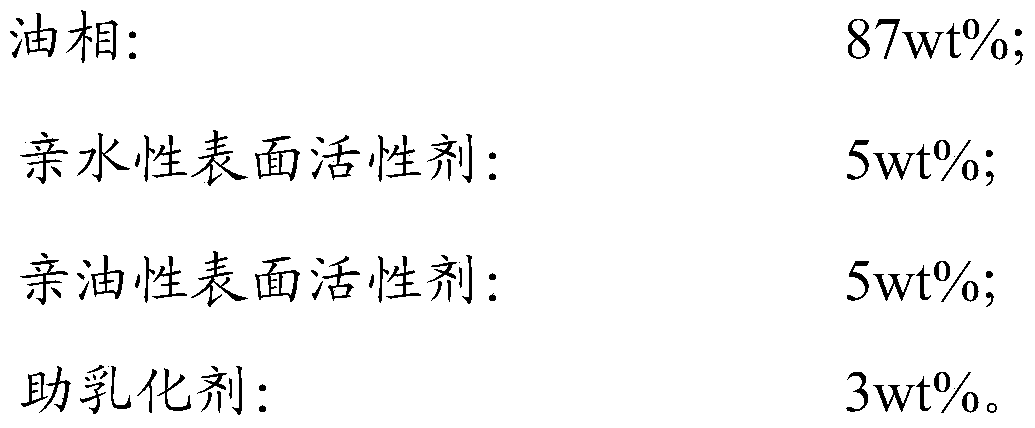

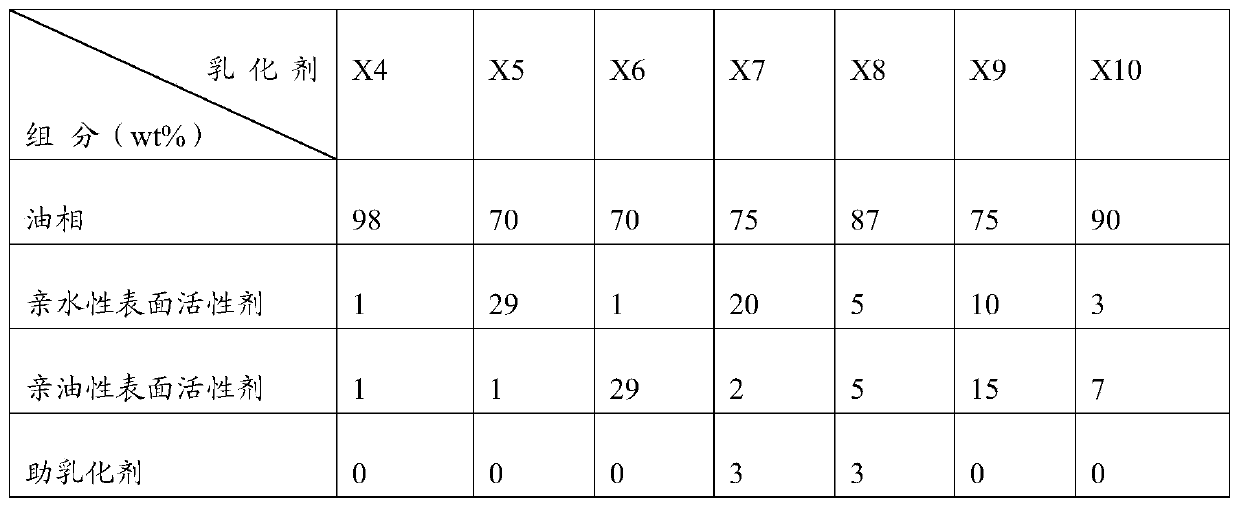

[0057] The emulsifying agent of the present invention includes many kinds, because the raw material of each component and the selection of mass percentage are different, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com