Full-automatic polishing system and method for whole superconducting cavity surface chemical buffering

A technology of surface chemistry and superconducting cavity, which is applied in the field of ion accelerator superconducting cavity processing, can solve the problems of poor safety, single use object, poor reliability, etc., and achieve the effect of high safety and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the best examples shown in the accompanying drawings for further details:

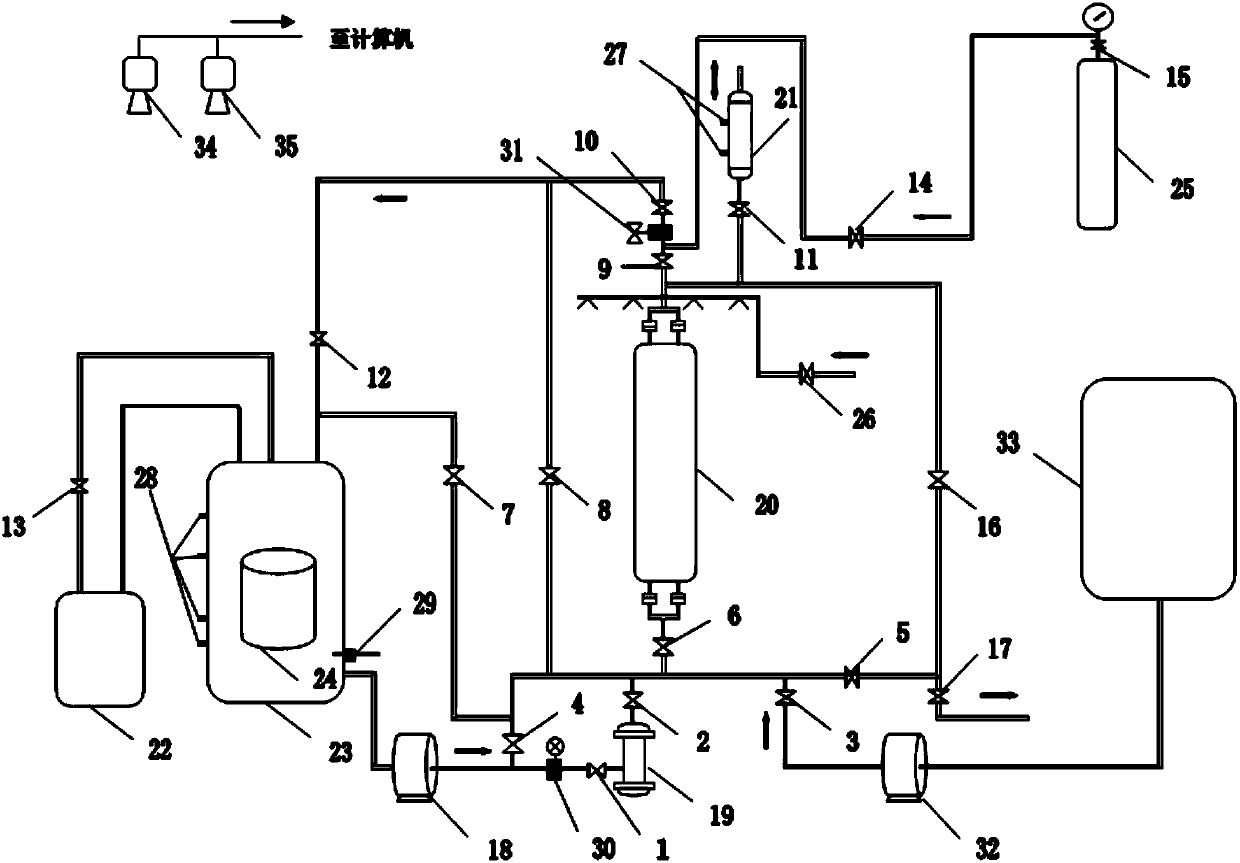

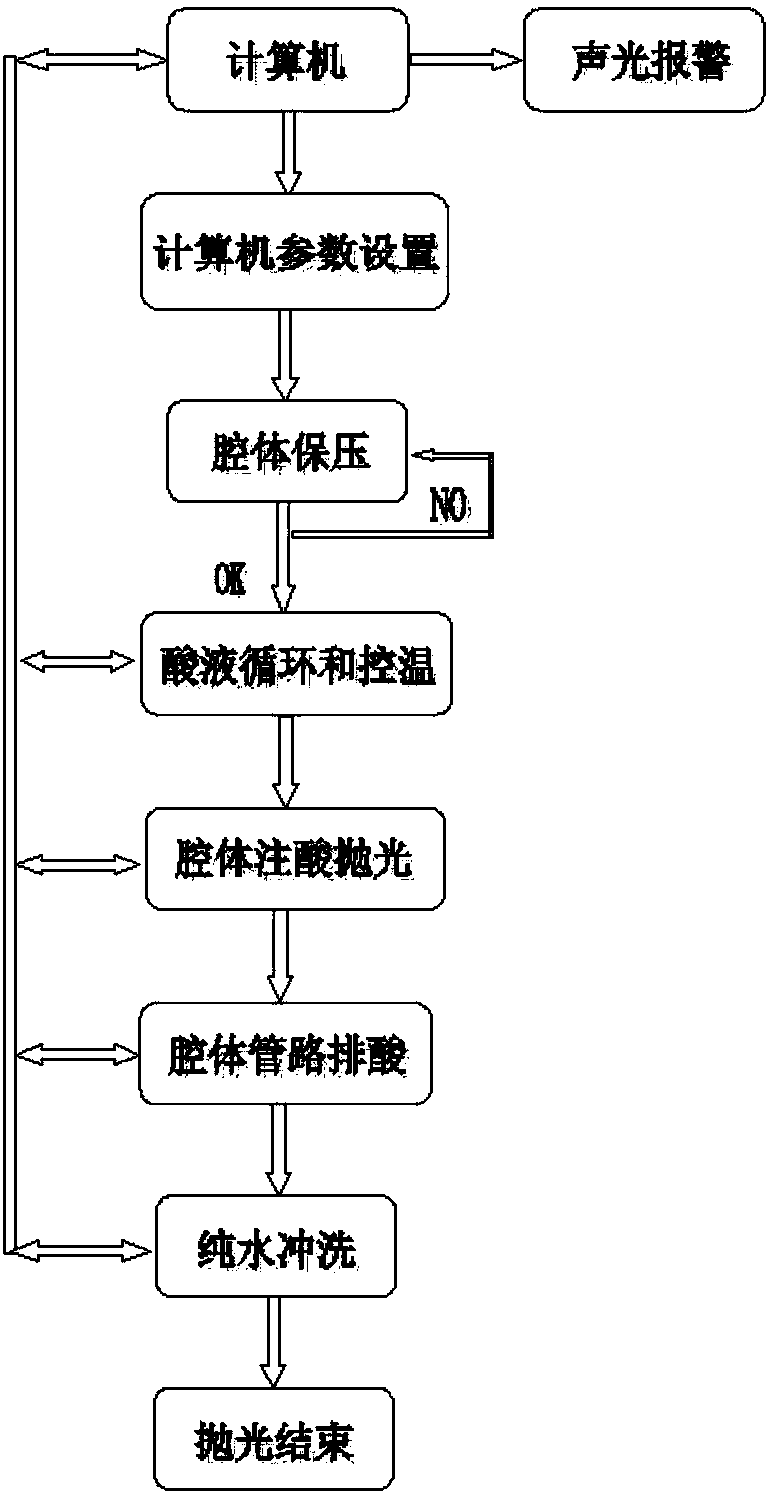

[0021] like figure 1 As shown, the chemical buffer automatic polishing system for the whole surface of the superconducting cavity is characterized in that it includes polishing equipment and a control system; The mixed acid tank 23 is provided with a heat exchanger 24, the lower end of the mixed acid tank 23 is connected to the acid liquid delivery pump 18 through a pipeline, the acid solution delivery pump 18 is connected to the filter 19 through the pipeline, and the filter 19 is connected to the supercharger through the pipeline. The lower end of the guide chamber 20 is connected to the ultrapure water pump 32, and the ultrapure water pump 32 is connected to the ultrapure water tank 33 through pipelines, and the upper end of the superconducting chamber 20 is connected to the upper end of the mixed acid tank 23 and the observation window 21 through pipelines, respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com