Method for measuring contents of carbon and sulfur in chromium ores

A determination method and technology for sulfur content, which are used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of inability to guarantee the accuracy of detection, narrow detection range of sulfur content, etc., and save reagents and personnel input. , the detection speed is fast, the result is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

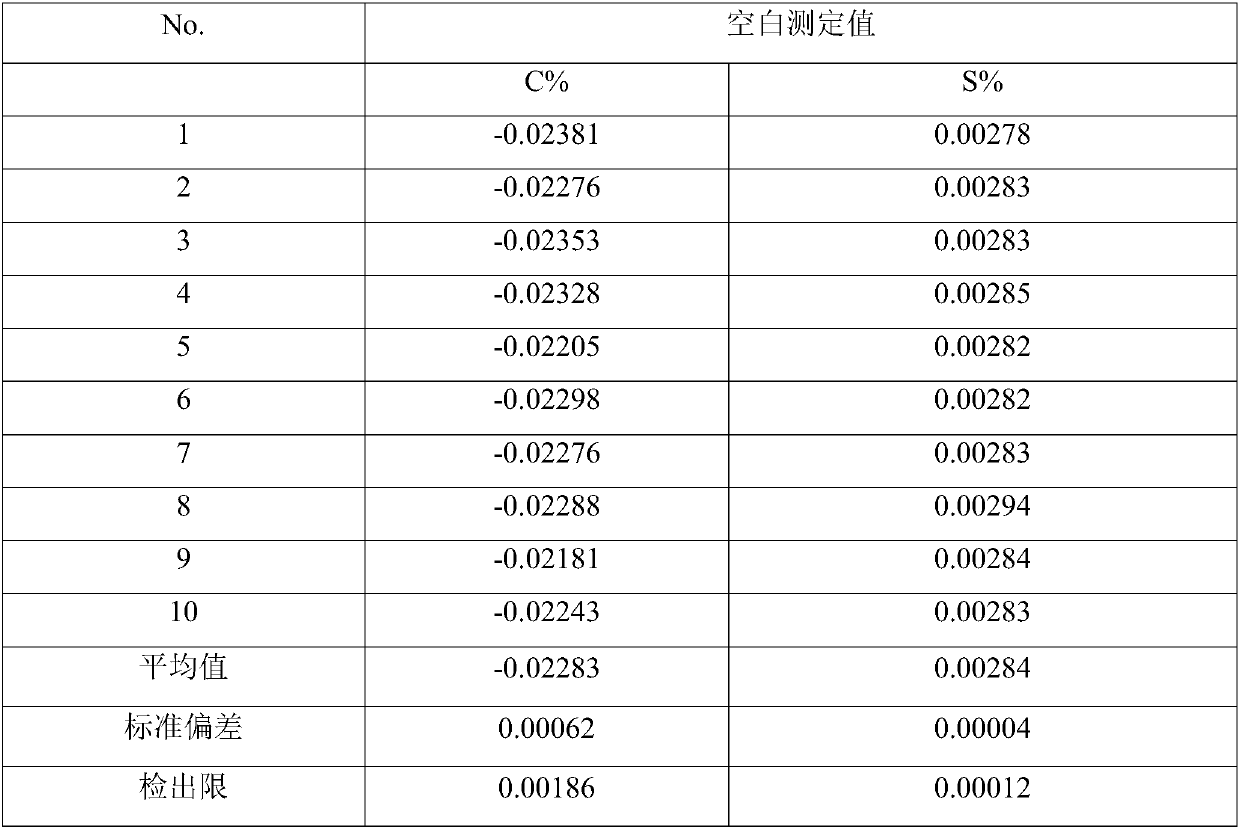

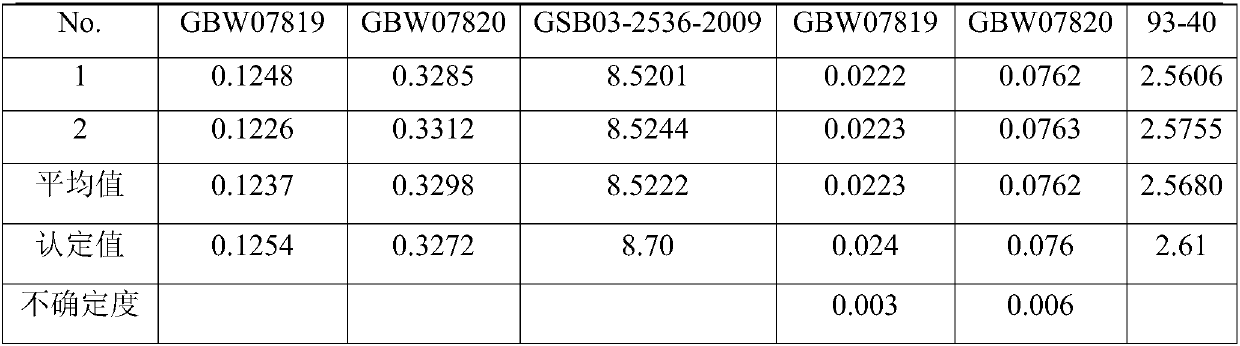

[0019] A method for measuring carbon and sulfur content in chrome ore, comprising the following steps:

[0020] S1. Crush the sample to pass through a 100-mesh sieve, then dry it in an oven at 60°C for 4 hours, and then cool it to room temperature in a desiccator;

[0021] S2. Weigh 0.05-0.5 parts by weight of the sample to be tested and place it in a burnt crucible with 0.38-0.42 parts by weight of pure iron flux on the bottom, and cover the surface of the sample to be tested with 1.1-1.3 parts by weight of tungsten particles and 0.24 parts by weight. ~0.26 parts by weight of tin particles are detected by a high-frequency infrared carbon-sulfur analyzer to obtain the content of carbon and sulfur.

[0022] In a preferred embodiment, the sample to be tested is 50-500 mg, the pure iron flux is 0.4 g, the tungsten particle is 1.2 g, and the tin particle is 0.25 g.

[0023] In a preferred embodiment, the absolute value of the sulfur content in the sample to be tested is not more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com