Low-sugar wormwood leaf honey bread and preparation method thereof

A honey and wormwood technology, applied in dough processing, baking, baked food and other directions, can solve the problems of not being able to take white sugar casually, weak metabolic system, etc., to achieve scientific and reasonable formula matching, increase flavonoid content, and rigorous material selection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

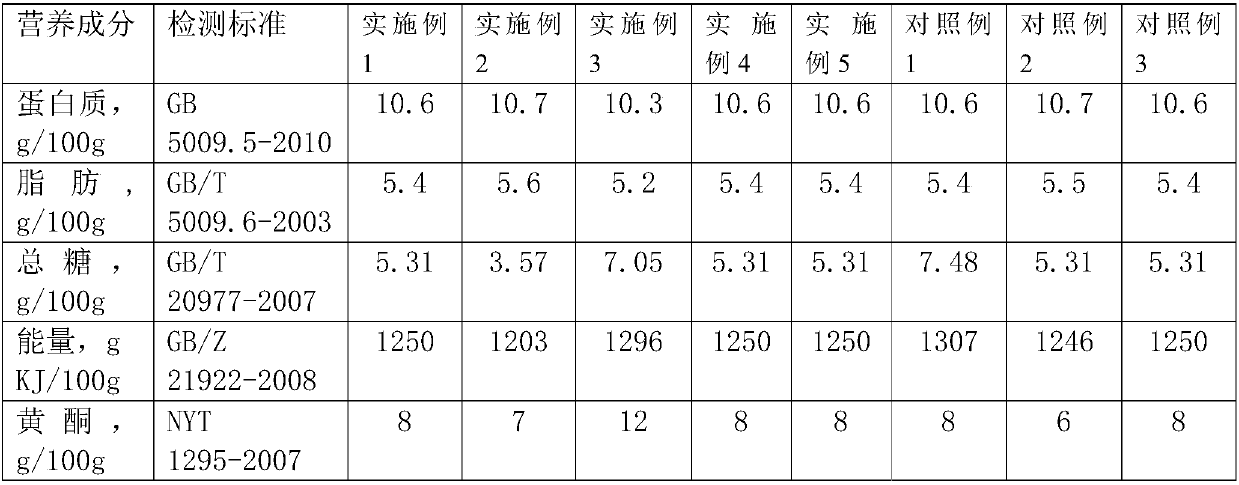

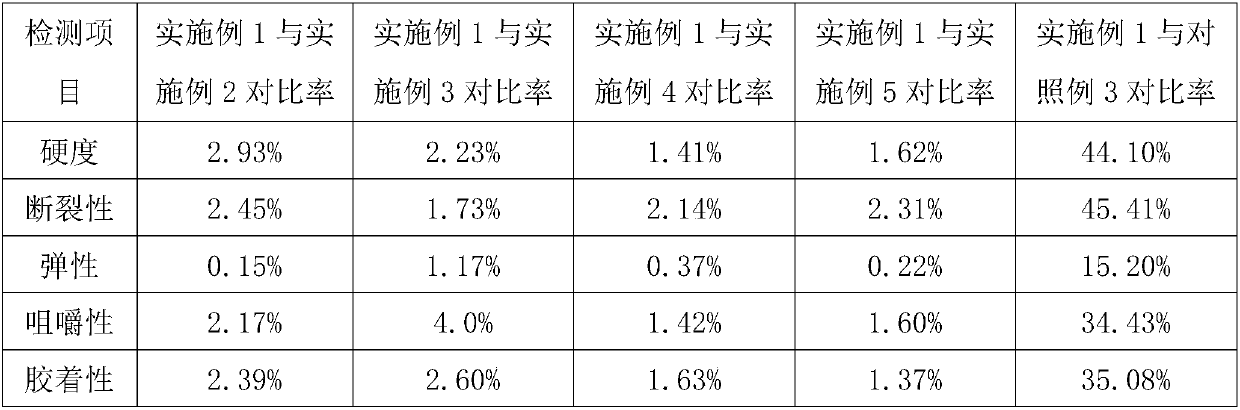

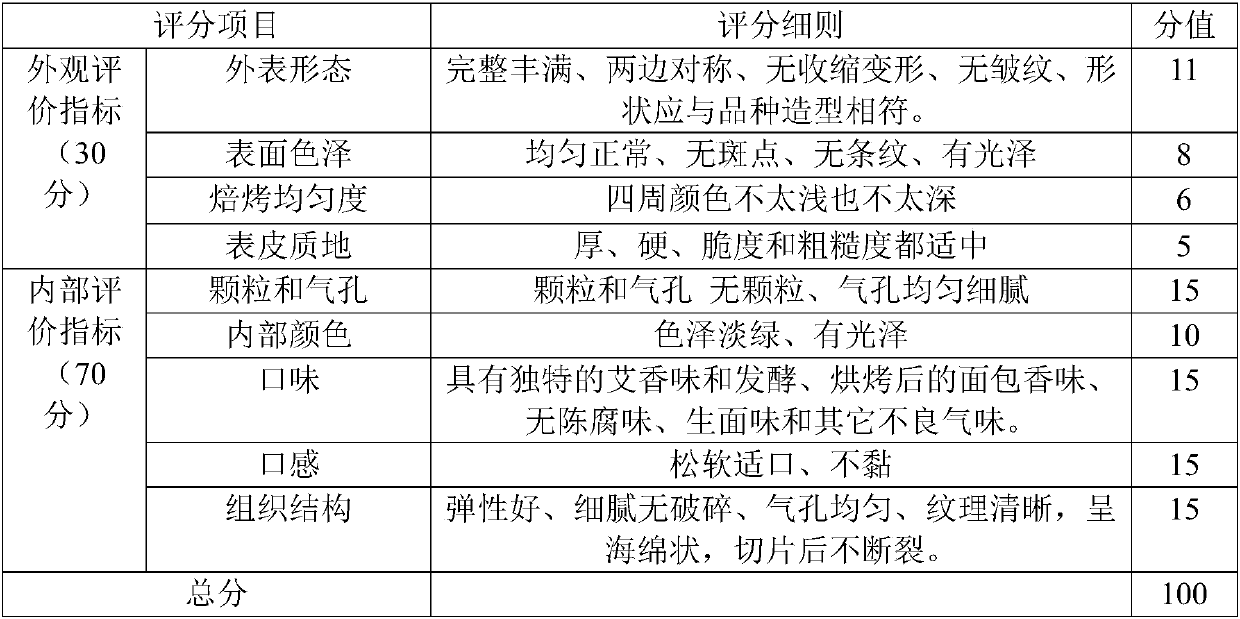

Examples

Embodiment 1

[0022] A low-sugar wormwood honey bread, the preparation process is as follows:

[0023] (1) Soak the dough and let it stand still: Pour 1000 grams of high-gluten flour, 100 grams of wormwood powder, and 350 grams of water into a two-speed double-action mixer and stir until it is picked up, then take it out and seal it for 30 minutes;

[0024] (2) Dough mixing: add the dough after resting in (1) to the mixer, and add 85 grams of whole egg liquid, 10 grams of salt, 3 grams of improver, 15 grams of low-sugar instant dry yeast, 280 grams of honey, and 100 grams of butter. grams, 100 grams of water, stir until the gluten is completely formed, take out the dough and knead it into a ball;

[0025] (3) proofing for the first time: putting the gluten formed in step (2) into a proofing box with a temperature of 30°C and a humidity of 85%, and proofing for 20 minutes;

[0026] (4) Bread shaping: take out the dough and divide it into 100g / piece, roll it 10 times, round it and put it on ...

Embodiment 2

[0030] A low-sugar wormwood honey bread, the wormwood powder in Example 1 is replaced by 50 grams of the lowest value, honey is replaced by 180 grams of the lowest value, the rest of the raw materials and dosage are the same as in Example 1, and the preparation process is the same as in Example 1 1 is the same.

Embodiment 3

[0032]A low-sugar wormwood soft bread raw material is: except that 100 grams of wormwood powder in Example 1 is replaced with 300 grams of the highest value, and 280 grams of honey is replaced with 380 grams of the highest value, the rest of the raw materials and dosage are the same as those in Example 1 Same, the preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com