Novel cleaning and placing system for medical drill bit

A drill bit, a new type of technology, applied in the fields of application, medical science, dentistry, etc., can solve the problems that affect the cleaning effect of the drill bit, cannot adjust the air intake, reduce the service life and other problems, and achieve the effect of avoiding pollution, preventing heating expansion and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

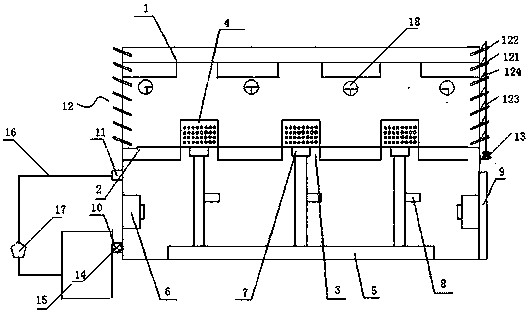

[0024] This embodiment is used for the novel cleaning and placing system of medical drill bit, comprises box body 1, and box body 1 is divided into upper, middle and lower three layers, is separated by two partition boards 2 that are arranged in cabinet body 1, and on partition board 2 Offer through groove 3, be provided with drill bit placement seat 4 in through groove 3, drill bit placement seat 4 is driven by the elevating cylinder 5 that bottom is provided with and moves between casing 1 upper strata, the middle stratum and the lower strata.

[0025] The middle tank is equipped with a water distribution system correspondingly. The water distribution system includes 4 water supply pipes 18. The 4 water supply pipes 18 are arranged in parallel in the box body 1 and are located on both sides of the channel 3. The axis of each water supply pipe 18 is the cross coordinate system. At the origin, the left water supply pipe 18 is located in the fourth quadrant area on the cross coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com