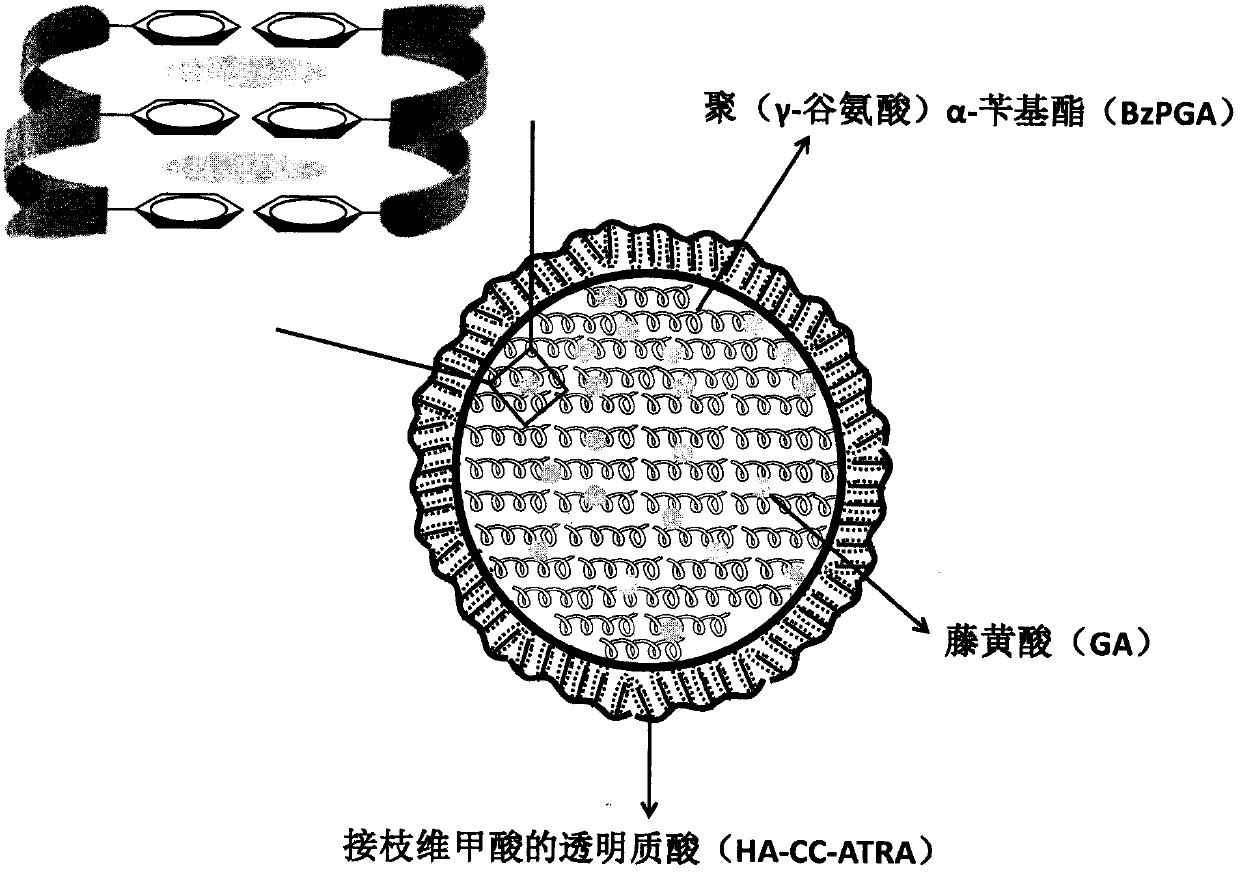

Gambogic acid core-shell structure composite nanometer preparation and preparation method thereof

A nano-formulation, core-shell structure technology is applied in the field of gambogic acid core-shell structure composite nano-formulation and its preparation, and can solve problems such as affecting drugability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] Preparation of poly(γ-glutamic acid)-hexadecyltrimethylammonium complex:

[0138] Weigh 10 g of poly(γ-sodium glutamate) with a molecular weight of 100 KDa, dissolve it in 200 mL of water, add 3% cetyltrimethylammonium bromide aqueous solution dropwise under stirring until no precipitation occurs, and depressurize The precipitate filtered by suction was washed three times with an appropriate amount of hot water, and dried in vacuo to obtain 21.53 g of a white solid, which was poly(γ-glutamic acid)-hexadecane prepared from poly(γ-sodium glutamate) with a molecular weight of 100KDa. Alkyltrimethylammonium complex (expressed as γ-P gambogic acid-CTA-100KDa).

Embodiment 2

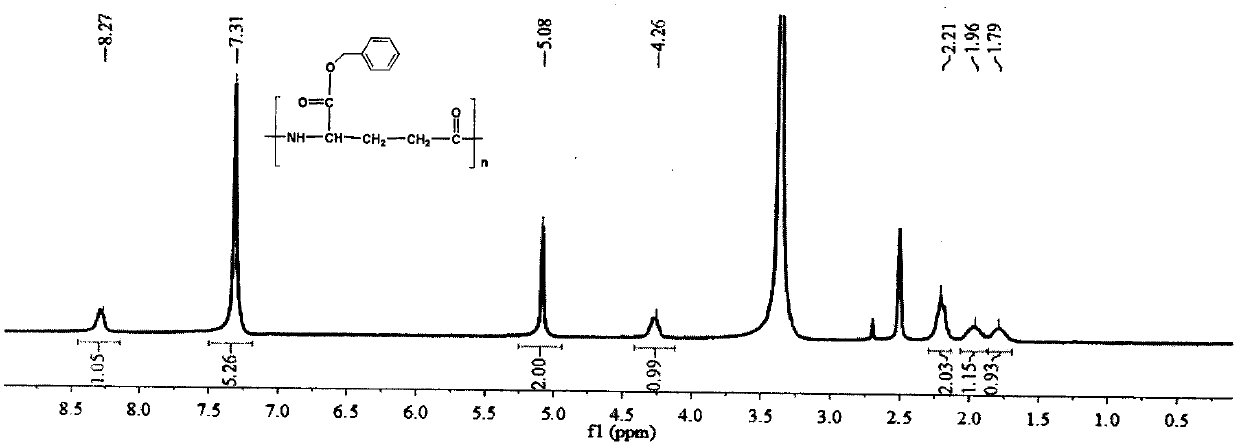

[0140] Preparation of poly(γ-glutamic acid)α-benzyl ester:

[0141] Take 2 g of γ-P gambogic acid-CTA-100KDa (containing 4.84 mmol of glutamic acid units), dissolve it in 60 mL of NMP, add 1.22 g of NaHCO 3 (14.52mmol), 0.414mL benzyl bromide (5.33mmol), heated and stirred at 50°C to dissolve the γ-P gambogic acid-CTA complex, and reacted at 50°C for 8h. After the reaction finishes, let it stand for cooling, and filter to remove insoluble matter (excessive NaHCO 3 and the generated NaBr), the filtrate was poured into 200mL of methanol, and then 100mL of 4% aqueous hydrochloric acid was added, stirred for 0.5h in an ice bath, filtered under reduced pressure, and washed three times with an appropriate amount of cold methanol:water (2:1), and the obtained precipitate was dissolved In 50mL NMP, repeat the above operation, and vacuum dry to obtain 0.9044g of white powder, which is poly(γ-glutamic acid)α-benzyl poly(γ-glutamic acid sodium) with a molecular weight of 100,000 Da. Es...

Embodiment 3

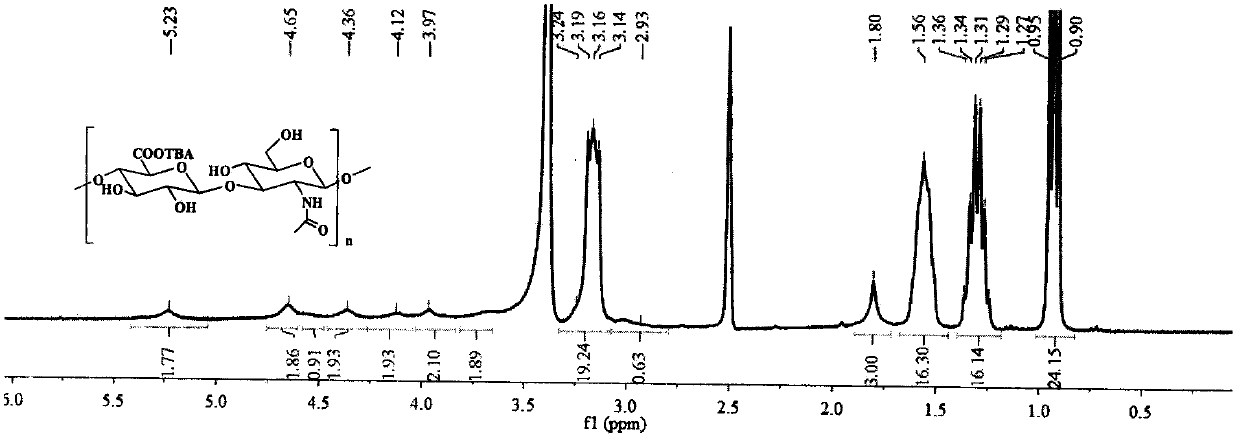

[0144] Acidification of sodium hyaluronate and preparation of hyaluronic acid-tetrabutylammonium complex:

[0145] Take 31.5 g of the pretreated strong-acid ion-exchange resin, wash it with deionized water until neutral. Weigh 9 g of HA-Na (14600 Da), add 450 mL of deionized water to obtain a 2% (w / v) HA-Na aqueous solution, add it to a strong acid ion exchange resin column, stir at room temperature for 6 hours, and check the exchange effect with pH test paper. HA aqueous solution was obtained by filtration (the pH of 2% w / v HA-Na aqueous solution was 6-7, and the pH of 2% w / v HA aqueous solution was 3).

[0146] Take 25% TBA-OH aqueous solution and add it dropwise to the above HA aqueous solution under stirring at room temperature until the pH of the solution system is ~7 (a total of 21 mL of TBA-OH aqueous solution is used), freeze-dry to obtain 13.6 g of white solid, which is transparent Hyaluronic acid-tetrabutylammonium complex (HA-TBA), which 1 H-NMR see image 3 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com