Manufacturing method of license plate of automobile

A technology for automobile signs and manufacturing methods, applied in vehicle parts, transportation and packaging, etc., can solve the problems of reducing the product appearance compliance rate and product qualification rate, and can not effectively avoid dust, stains, etc., to achieve increased production capacity and high qualified rate. , the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

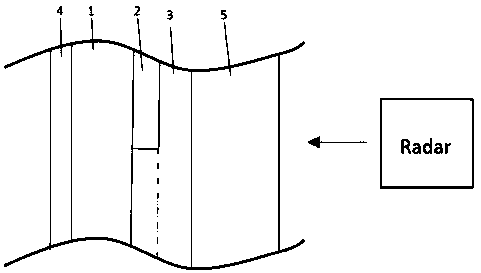

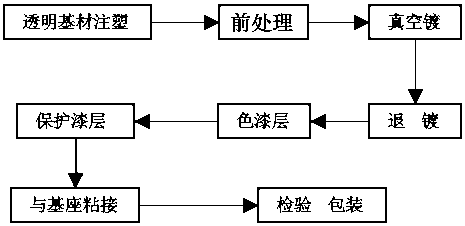

[0052] The car label of a certain type of car, the product structure section is shown in figure 1 . Process route see figure 2 .

[0053] The signboard corresponds to a radar frequency of 24.1GHZ, requiring the total thickness of the part (section Figure 1-2 ) is 7.65±0.15mm, the transparent substrate and the base are made of thermoplastic engineering plastic polycarbonate, which is heat-resistant, impact-resistant, creep-resistant and has good dimensional stability.

[0054] The transparent base material is formed into a required signage base material 1 of a certain shape by means of injection molding.

[0055] After the signage base material is injection molded, it needs to be baked at 110°C for 2 hours for stress relief. After the baking is completed, put the signage base material into a vacuum plating tool to remove dust and static electricity.

[0056] Vacuum coating 2 is divided into two layers, with a total thickness of less than 1 μm. The first indium alloy layer...

Embodiment 2

[0063] The car label of a certain type of car, the product structure section is shown in figure 1 . Process route see figure 2 .

[0064] The signboard corresponds to a radar frequency of 24.1GHZ, requiring the total thickness of the part (section Figure 1-2 ) is 7.65±0.15mm, the transparent substrate and the base are made of thermoplastic engineering plastic polycarbonate, which is heat-resistant, impact-resistant, creep-resistant and has good dimensional stability.

[0065] The transparent base material is formed into a required signage base material 1 of a certain shape by means of injection molding. After the sign base material is injection molded, it needs to be baked for stress relief at 110°C for 2 hours.

[0066] After finishing, put the base material of the signage into the vacuum plating tooling to remove dust and static electricity.

[0067] Vacuum coating 2 is divided into two layers, with a total thickness of less than 1 μm. The first indium alloy layer is ...

Embodiment 3

[0074] The car label of a certain type of car, the product structure section is shown in figure 1 . Process route see figure 2 .

[0075] The signboard corresponds to a radar frequency of 24.1GHZ, requiring the total thickness of the part (section Figure 1-2 ) is 7.65±0.15mm, the transparent substrate and the base are made of thermoplastic engineering plastic polycarbonate, which is heat-resistant, impact-resistant, creep-resistant and has good dimensional stability.

[0076] The transparent base material is formed into a required signage base material 1 of a certain shape by means of injection molding. After the sign base material is injection molded, it needs to be baked for stress relief at 110°C for 2 hours.

[0077] After finishing, put the base material of the signage into the vacuum plating tooling to remove dust and static electricity.

[0078] Vacuum coating 2 is divided into two layers, with a total thickness of less than 1 μm. For the first indium alloy layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com