Drying transportation container

A container and drying technology, which is applied in the direction of transportation and packaging, transport passenger cars, packaging, etc., can solve the problems of increasing costs and affecting the efficiency of the production chain, and achieve the effects of cost saving, good market prospects, and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

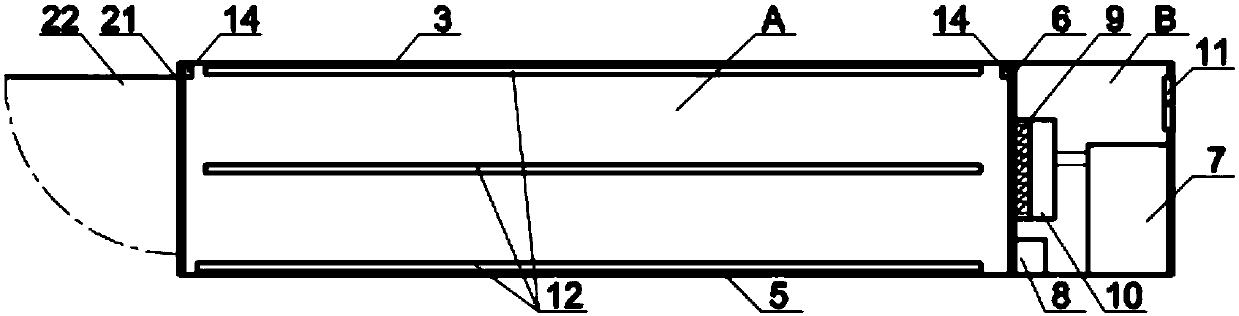

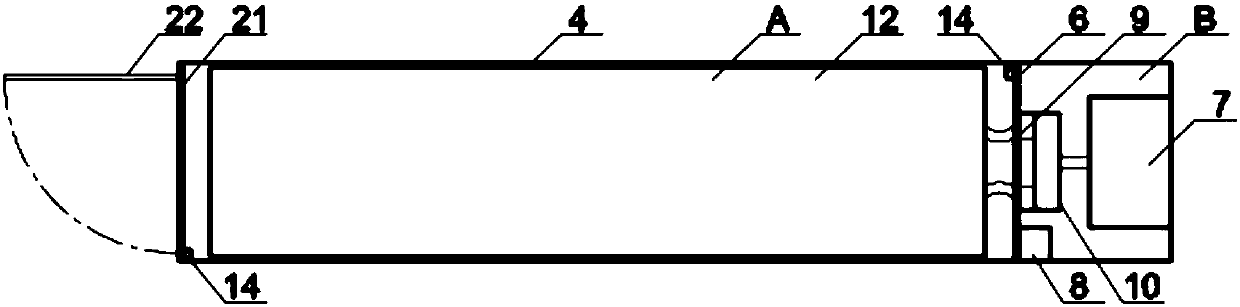

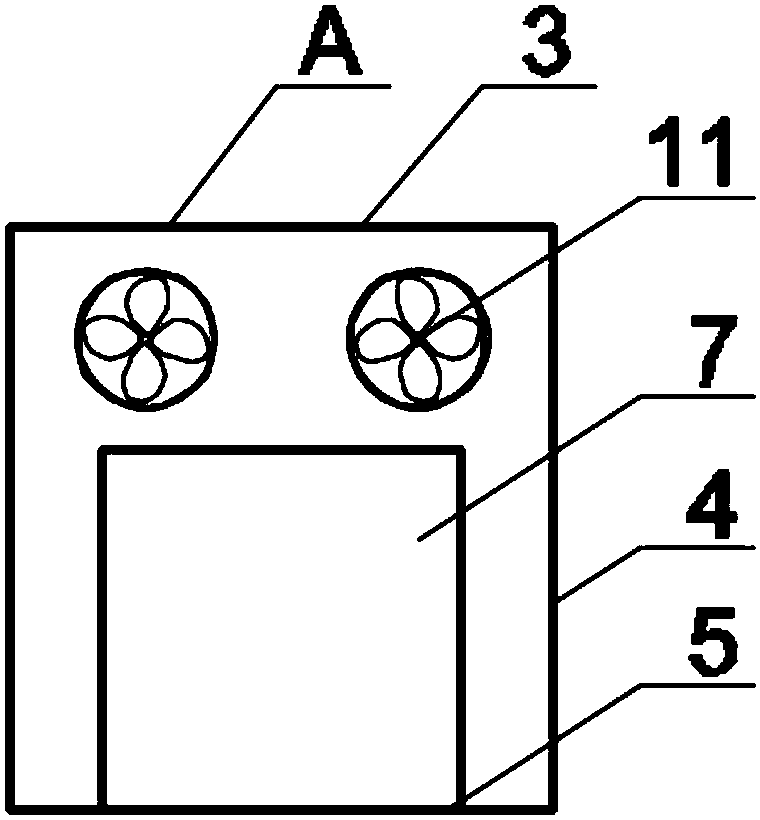

[0021] Hereinafter, the dry transport container related to the invention will be described in detail with reference to the accompanying drawings.

[0022] Such as figure 1 , figure 2 As shown, the present invention discloses a dry transport container, which integrates transport and drying functions. The box body is mainly bounded by a partition 6 and is divided into two parts: a cargo area A and an equipment area B. The loading area A includes the door 2, the top plate 3, the side plate 4, the bottom plate 5, the electrode plate 12 and the temperature and humidity monitor 14, and the equipment area B includes the high-frequency oscillator 7, the water tank 8, the heating plate 9, and the axial flow fan 10 and exhaust fan 11. The box door 2 includes an inner door 21 and an outer door 22 . The door 2, the top plate 3, the side plate 4, the bottom plate 5, and the partition plate 6 are all provided with thermal insulation layer or thermal insulation coating, and the inner sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com