Preparation method of acetylacetone dicarbonyl rhodium and mixed C4 hydroformylation method

A technology of acetone dicarbonyl rhodium and acetylacetone, applied in the field of formylation catalysts, can solve the problems of high reaction temperature, low yield and high chlorine content in products, and achieves the effects of mild reaction conditions, high reaction rate and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

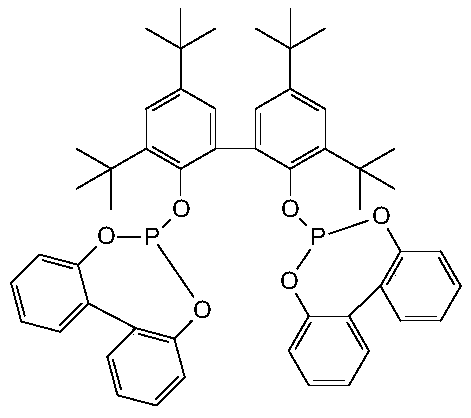

[0016] The invention provides a method for preparing rhodium dicarbonyl acetylacetonate, which comprises the following steps: stirring and mixing an aqueous solution of rhodium oxide hydrate, an organic carboxylic acid catalyst and acetylacetone, heating to 60-120°C, preferably 80-100°C, and then feeding Carbon monoxide is reacted, and after the reaction is completed, the reaction liquid is cooled and filtered, the filter cake is washed with deionized water, and the wet base product of rhodium acetylacetonedicarbonyl is obtained after suction filtration, which can be used for rhodium in mixed carbon tetrahydroformylation reactions. catalyst. The concentration of the hydrated rhodium oxide aqueous solution is 0.010-2.00 mol / liter, preferably 0.10-1.00 mol / liter; the amount of acetylacetone added is such that the molar ratio of acetylacetone to rhodium is 1.0-10.0, preferably 3.0-8.0, More preferably 4.0~6.0; The organic carboxylic acid is selected from one or more of C2~C20 org...

Embodiment 1

[0031] This embodiment is used to illustrate the preparation method of rhodium acetylacetonate dicarbonyl provided by the present invention.

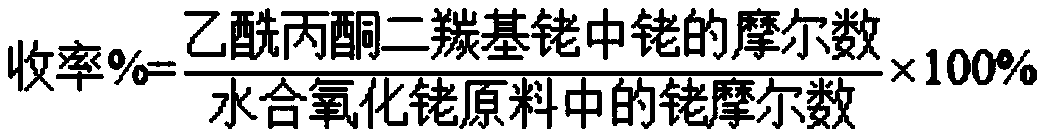

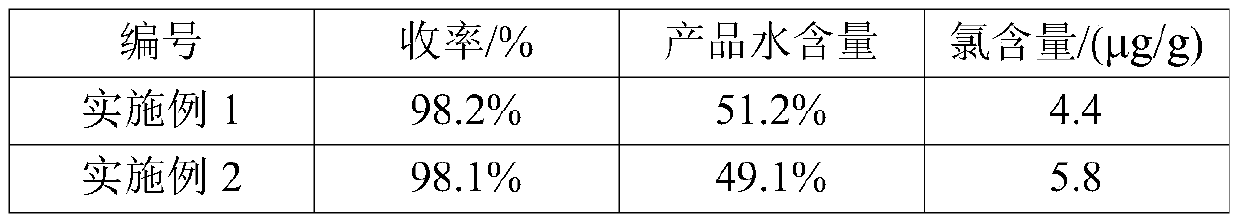

[0032] In a round-bottomed three-neck flask equipped with a condenser tube and gas inlet and outlet pipelines, dissolve rhodium oxide hydrate containing 0.03mol rhodium in 300mL deionized water, add 0.0003mol acetic acid and 0.24mol acetylacetone, stir and mix, and replace with nitrogen three times Afterwards, be warming up to 100 ℃, pass into carbon monoxide (purity 99.9 volume %) gas with the flow rate of 15 milliliters / minute, react under stirring for 2 hours, after the completion of the reaction, the reaction solution is cooled, and a blood-red solid is separated out, filtered, washed with deionized water, After suction filtration, the rhodium dicarbonyl acetylacetonate wet base is obtained, and the rhodium dicarbonyl acetylacetonate yield can be calculated by detecting the rhodium content in the product and the raw material. The yi...

Embodiment 2

[0034] This embodiment is used to illustrate the preparation method of rhodium acetylacetonate dicarbonyl provided by the present invention.

[0035] In a round-bottomed three-neck flask equipped with a condenser tube and gas inlet and outlet pipelines, dissolve hydrated rhodium oxide containing 0.03mol rhodium in 30mL deionized water, add 0.003mol propionic acid and 0.18mol acetylacetone, stir and mix, and replace with nitrogen After three times, heat up to 80°C, feed carbon monoxide (purity 99.9% by volume) gas at a flow rate of 15 ml / min, and react for 2 hours under stirring. After the reaction is completed, the reaction liquid is cooled, and a blood-red solid is precipitated, filtered, and washed with deionized water After suction filtration, the rhodium dicarbonyl acetylacetonate wet base is obtained, and the rhodium dicarbonyl acetylacetonate yield can be calculated by detecting the rhodium content in the product and the raw material. The yield and product analysis resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com