Bus type rapid connection belt conveyance system

A fast connection and belt conveying technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of manpower and time cost, difficulty, time-consuming and labor-intensive, etc., to save labor and time costs, on-site construction Convenience and ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

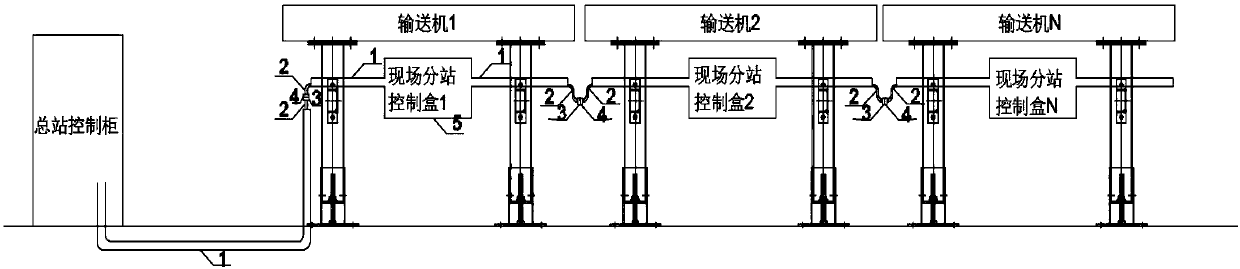

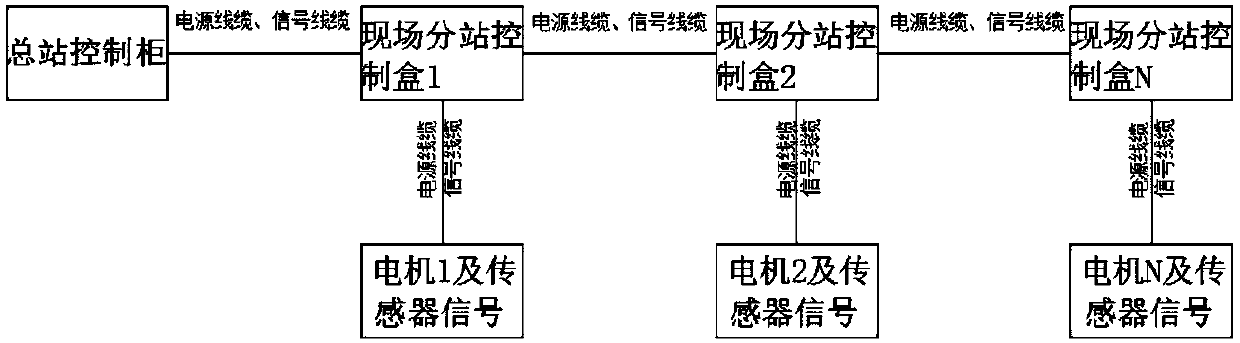

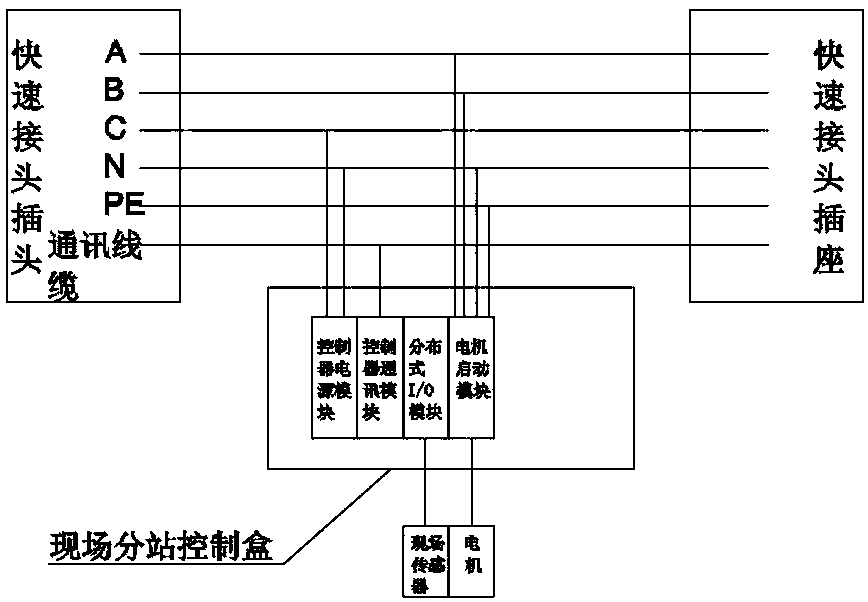

[0016] as attached figure 1 , figure 2 , image 3 , Figure 4 As shown, a bus-type quick-connect belt conveying system, for N conveyors, includes a main station control cabinet, N field sub-station control boxes, and the main station control cabinet includes a controller CPU module, a communication module, and a power cable , communication cables, after the power cables and communication cables 2 are drawn out from the threading pipe 1, a quick connector plug 3 is installed, and the on-site substation control box is provided with an incoming quick connector socket 4 and an outgoing quick connector plug 3 , the incoming line quick connector socket 4 and the outgoing line quick connector plug 3 are used for connecting the power cable and the communication cable 2 drawn out through the threading pipe, and by docking the quick connectors of the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com