A Stereoscopic Fabrication Method Based on Flexible and Deformable Microlens Array

A technology of microlens array and manufacturing method, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of limited 3D printing materials, printing three-dimensional shapes, product manufacturing errors, etc., and achieve simplified process flow, convenient production, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described below through the accompanying drawings and embodiments.

[0025] A three-dimensional manufacturing method based on a flexible deformable microlens array, comprising the following steps:

[0026] 1) placing microscopic particles 1 of micro-nano scale in pure water, stirring to make them evenly distributed, and obtaining an aqueous solution containing microscopic particles;

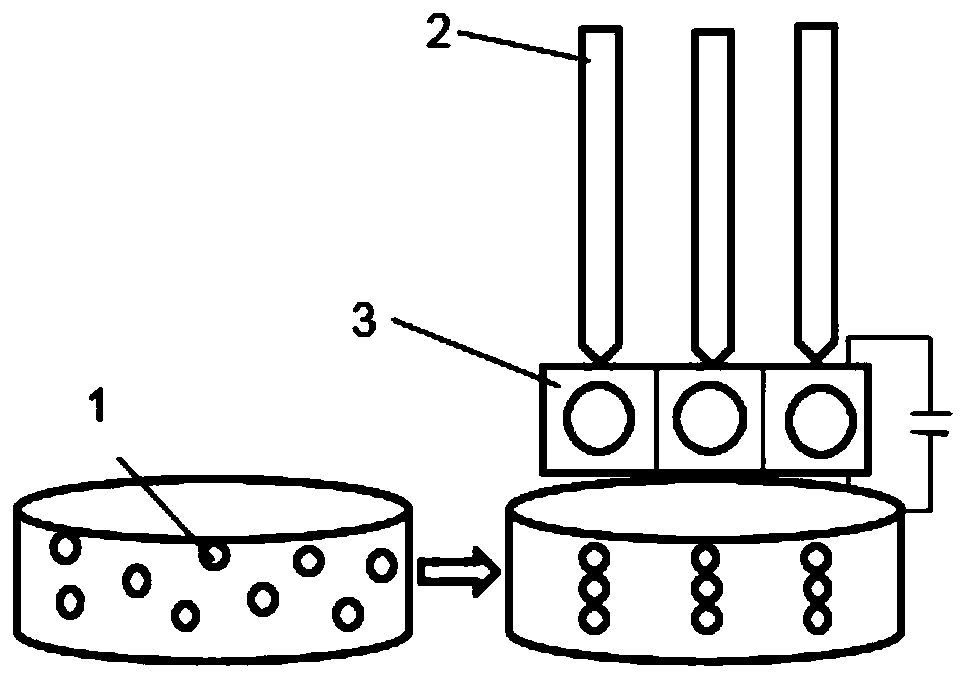

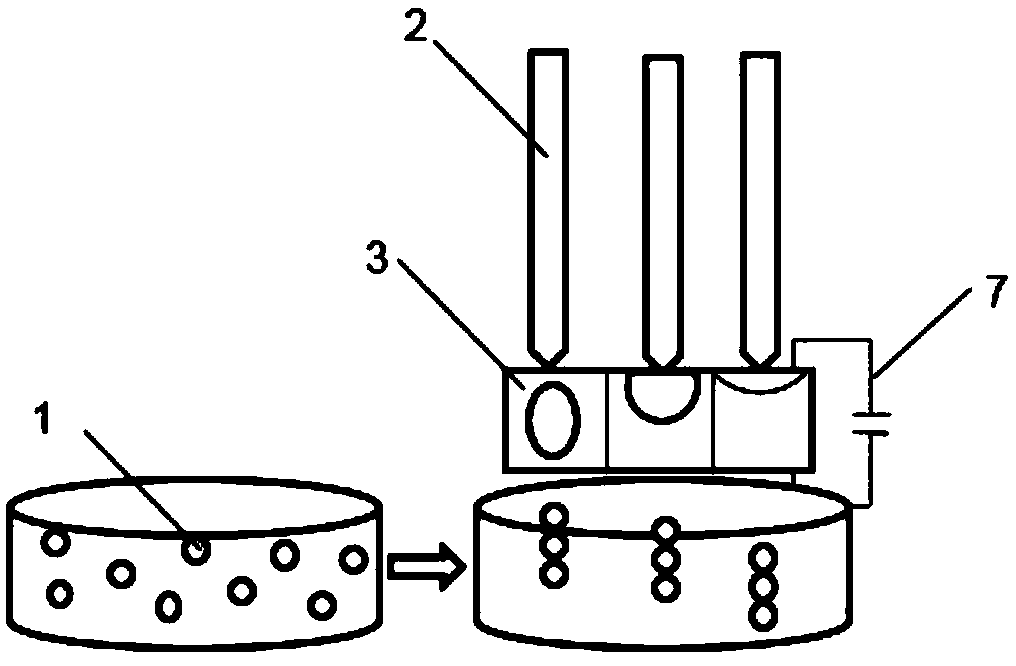

[0027] 2) The light is applied to the microscopic particles 1 through the optical fiber 2 and the flexible deformable microlens array 3. Since the flexible deformable microlens array 3 has a relatively high refractive index, an optical potential well can be formed at its exit end, thereby Microscopic particles 1 in aqueous solution are manipulated, such as figure 1 shown;

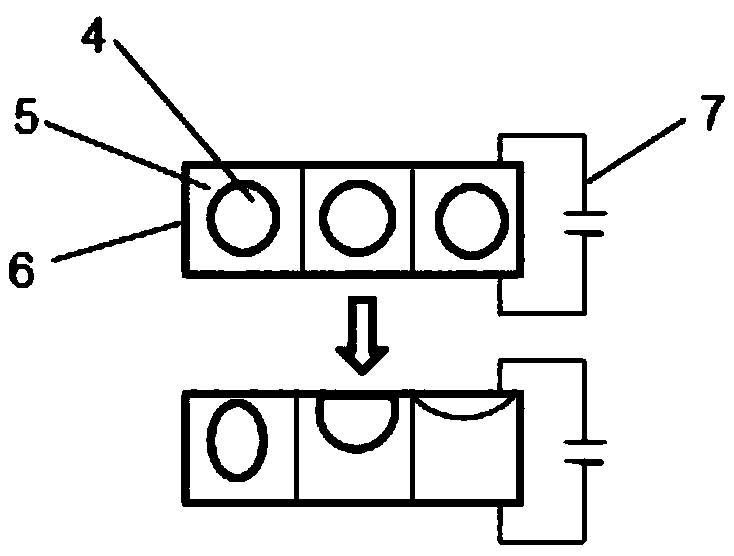

[0028] 3) Apply an inhomogeneous external field force to the flexible deformable m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com