Method for preparing 19-desmethyl-4-androstene-3,17-diketone by using one-pot method

A technology of androstene and diketone, which is applied in the field of chemical preparation, can solve the problems of long production cycle, complicated operation and high cost, and achieve the effects of high product quality, simple operation and short synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

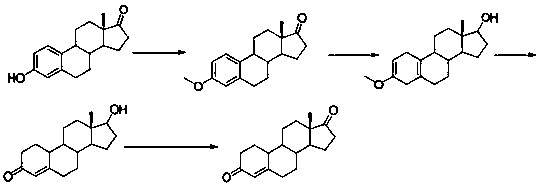

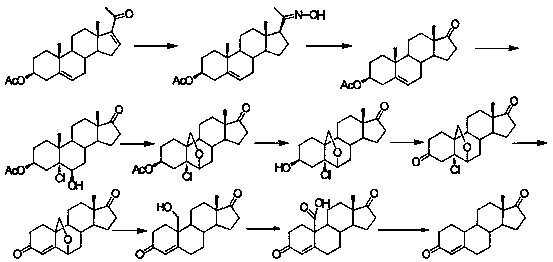

Method used

Image

Examples

Embodiment 1

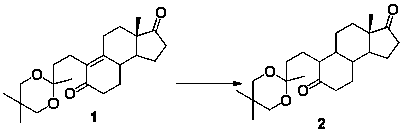

[0035] The first step, hydrogenation reaction: add compound 1 (75g, 1W) and absolute ethanol (375ml, 5V) to the reaction flask, stir, add Pd / C (7.5g, 0.1W) under nitrogen protection, replace nitrogen with hydrogen, and The temperature was controlled at 50~55°C, and the reaction was kept at this temperature for 6 hours. When there was no raw material point detected by TLC, filter, the filter cake was washed with ethanol (220ml, 2V), and the filtrate was evaporated to dryness at 50°C under reduced pressure to obtain the hydrogenated product 2;

[0036] The second step, condensation reaction: add phosphoric acid (90g, 0.8W) to the hydride 2, under the protection of nitrogen, stir and raise the temperature, the internal temperature is controlled at 75~80°C, keep the reaction at this temperature for 5 hours, TLC detects no raw material point Add drinking water (500ml, 6.67V) for water analysis, lower the temperature to 5~10°C, keep stirring for 2 hours, filter, wash the filter cake ...

Embodiment 2

[0038] The first step, hydrogenation reaction: add compound 1 (100g, 1W) and benzene (300ml, 3V) into the reaction flask, stir, add palladium carbon (1g, 0.5W) under the protection of nitrogen, replace the nitrogen with hydrogen, and control the internal temperature at 20°C , keep the reaction at this temperature for 15 hours, when there is no raw material point detected by TLC, filter, the filter cake is washed with benzene (400ml, 4V), and the filtrate is evaporated to dryness at 65°C under reduced pressure to obtain the hydrogenated product 2;

[0039] The second step, condensation reaction: add phosphoric acid (50g, 0.5W) to the hydrogenation product 2, under the protection of nitrogen, the internal temperature is controlled at 20°C, and the reaction is kept at this temperature for 24 hours. When there is no raw material point detected by TLC, drinking water is added (10000ml, 100V) water analysis, lower the temperature to 5~10°C, keep stirring for 2 hours, filter, wash the...

Embodiment 3

[0041] The first step, hydrogenation reaction: add compound 1 (224g, 1W) and methanol (672ml, 3V) into the reaction flask, stir, add active nickel (112g, 0.5W) under the protection of nitrogen, replace the nitrogen with hydrogen, and control the internal temperature at 80 ℃, keep the reaction at this temperature for 2 hours, when there is no raw material point detected by TLC, filter, the filter cake is washed with methanol (224ml, 1V), and the filtrate is evaporated to dryness at 65℃ under reduced pressure to obtain the hydrogenated product 2;

[0042] The second step, condensation reaction: add phosphoric acid (2240g, 10W) to the hydrogenation product 2, under the protection of nitrogen, stir and raise the temperature, control the internal temperature at 95°C, keep the reaction at this temperature for 3 hours, when there is no raw material point detected by TLC, add Drinking water (2240ml, 10V) water analysis, cooling to 5~10°C, heat preservation and stirring for 2 hours, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com