High-throughput roller bottle culture device

A culturing device and high-throughput technology, which can be used in tissue cell/virus culturing devices, biochemical instruments, biochemical equipment and methods, etc., which can solve the problem of poor synchronization between the culture flask and the roller, high requirements on the material of the culture flask, and sample size. Small and other problems, to achieve the effect of low culture cost, improved cell culture efficiency, and large sample size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

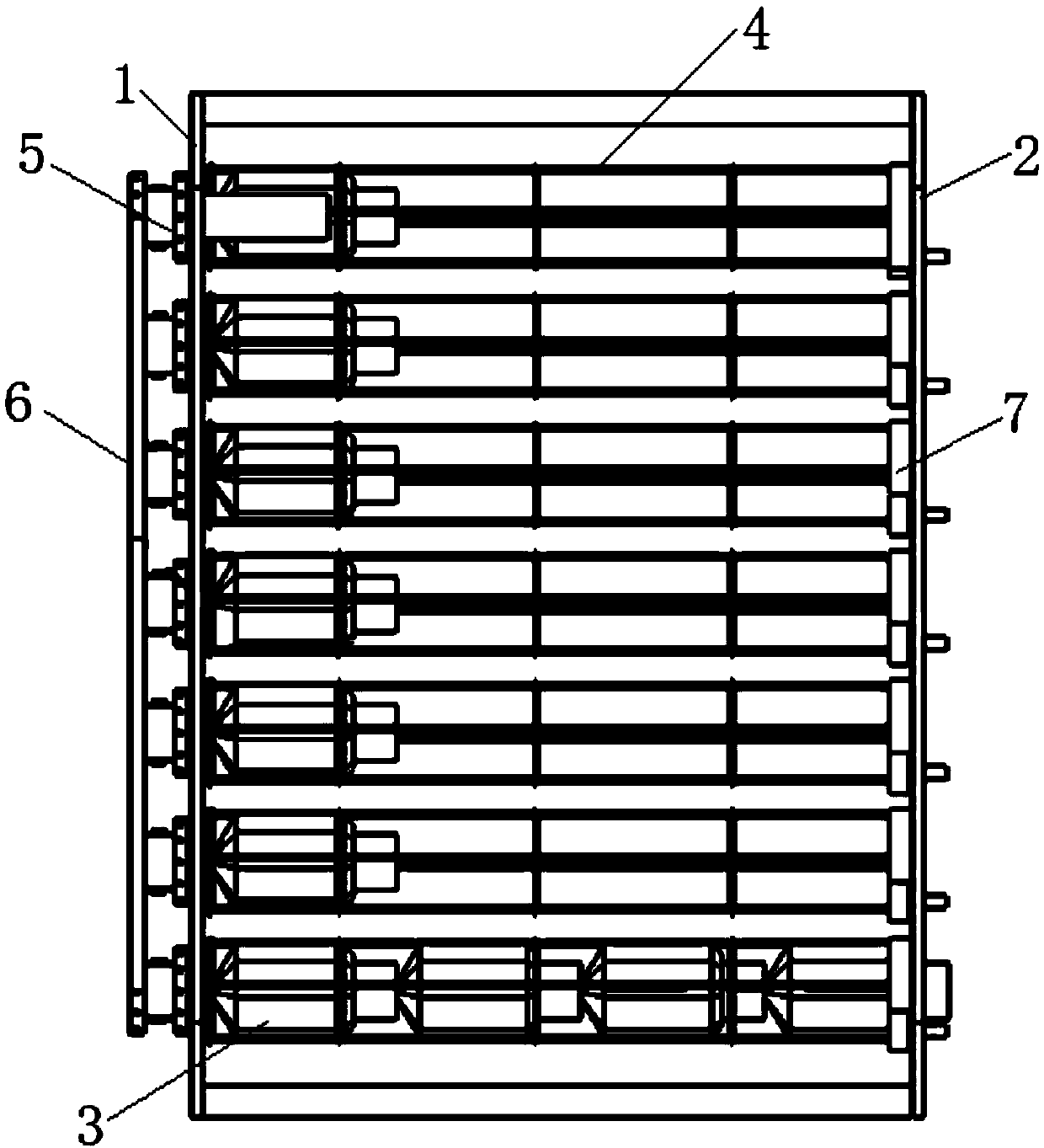

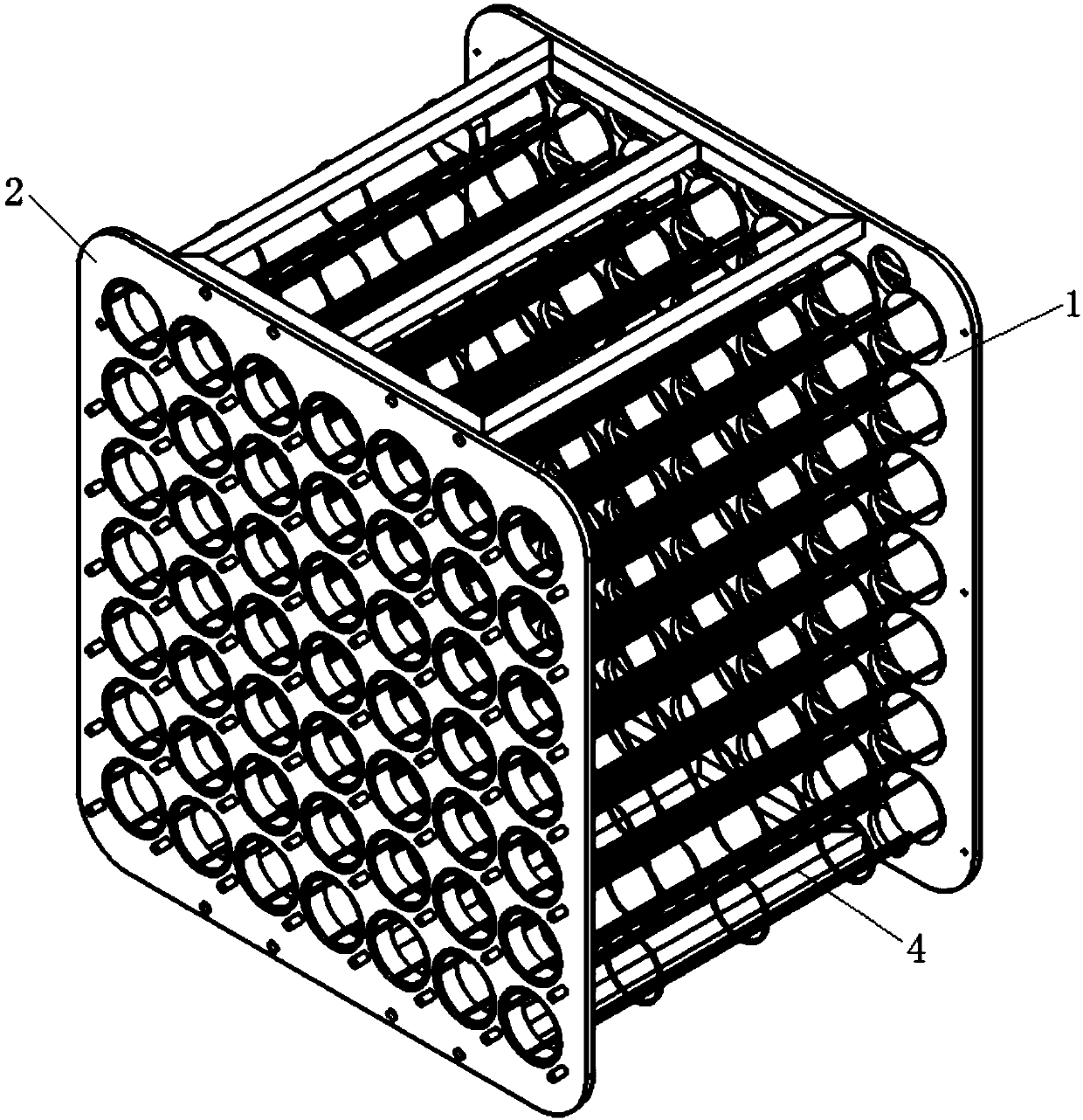

[0029] This embodiment provides a high-throughput roller bottle culture device, which is set in an incubator for cultivating cells efficiently and uniformly. The high-throughput roller bottle culture device is as follows: Figure 1-2 As shown, it includes a first panel 1 (rear panel) and a second panel 2 (front panel) for supporting and installing other components, and at least one inner diameter and roller are arranged between the first panel 1 and the second panel 2 The outer diameter of the bottle 3 is adapted to the sleeve part 4, and the roller bottle 3 is used for culturing cells. The sleeve part 4 is connected with a drive assembly for driving its rotation, and the drive assembly drives the sleeve part 4 to rotate and then drives the sleeve. The roller bottle 3 adapted to it in the cylinder part 4 rotates, and the traditional roller bottle is arranged on the top of the roller, and the friction force between the roller and the roller bottle is used to indirectly drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com