Online detection device and online detection method for machine-made sand

A detection device and detection method technology, applied in the direction of measuring device, weighing by removing certain components, instruments, etc., can solve the problem of low efficiency, inability to detect the particle size and shape of machine-made sand at the same time, and the inability to detect the particle shape of fine aggregate and other issues to achieve the effect of avoiding economic loss and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

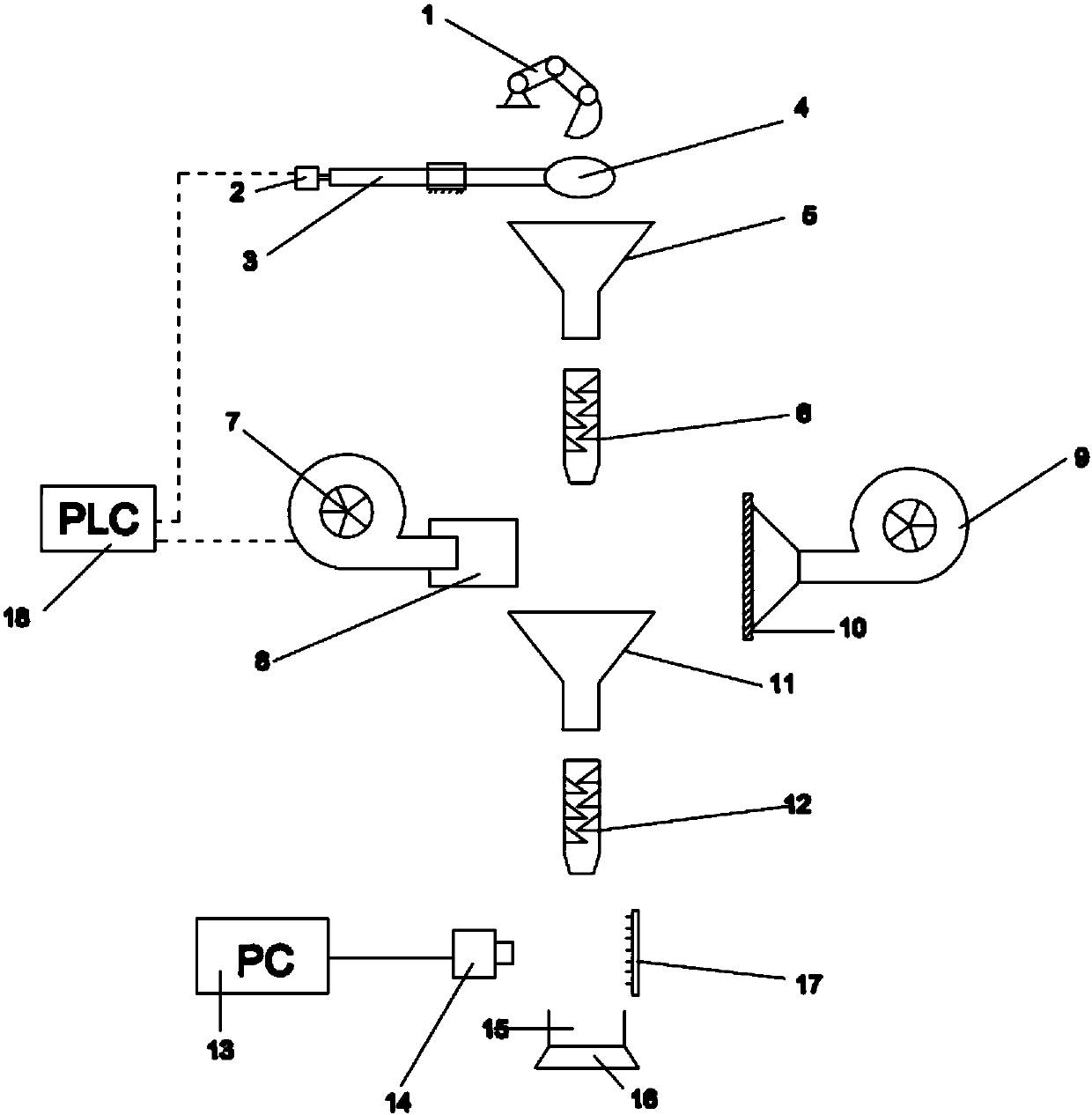

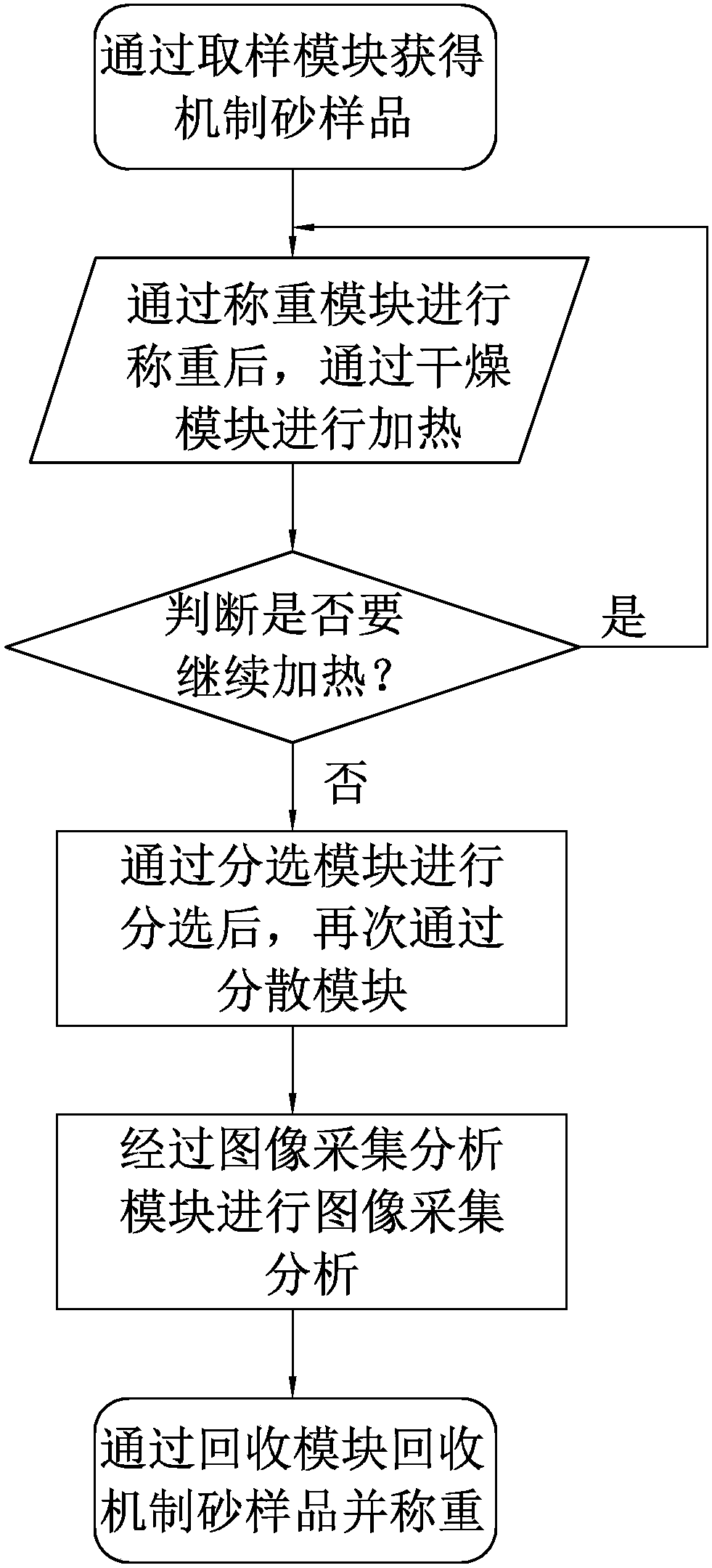

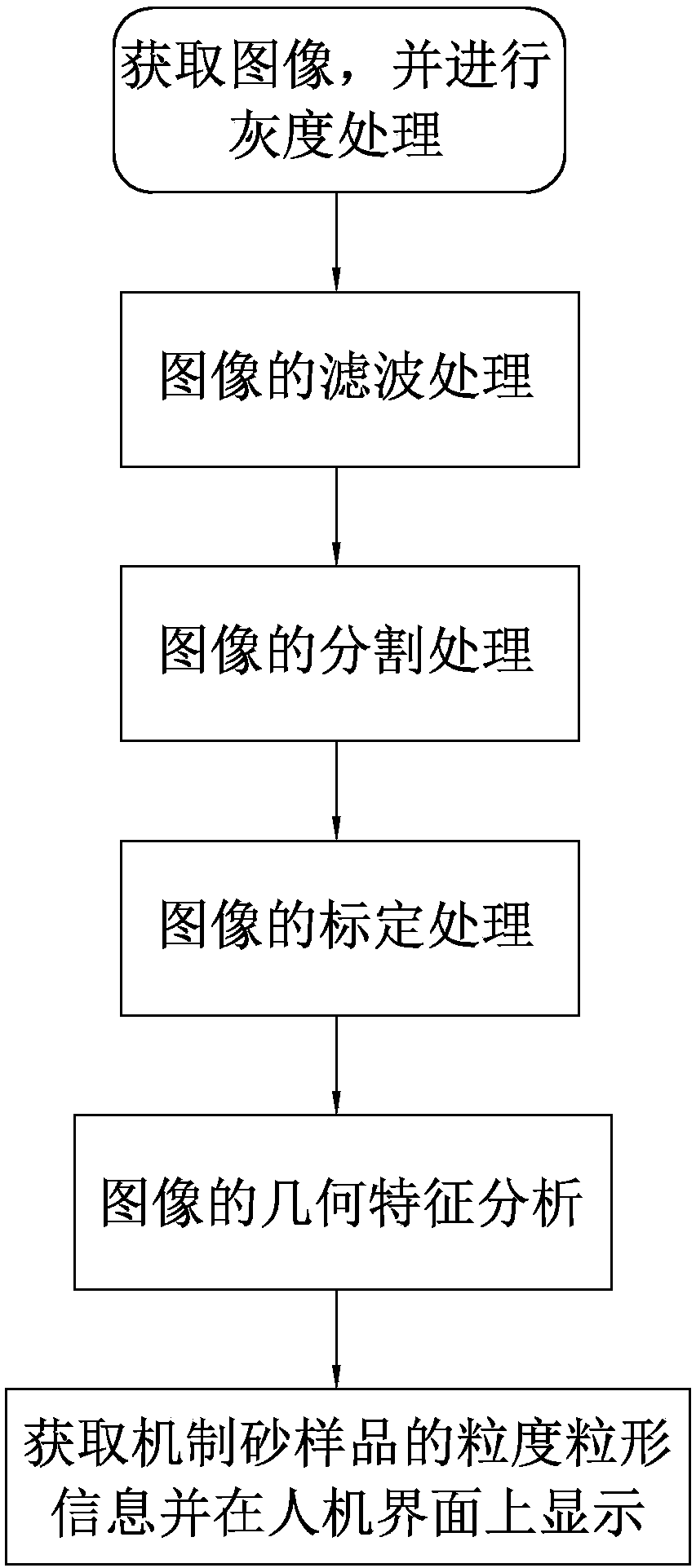

[0043] see Figure 1 to Figure 3 As shown, the present invention provides an online detection device for the quality of machine-made sand in order to realize instant reflection of the aggregate gradation, particle size, and grain shape of the current machine-made sand production line, which specifically includes: mechanical arm 1, conveying motor 2, scale handle 3. Weighing pan 4, feeding funnel 5, dispersion pipe 6, fan 7, fairing 8, vacuum cleaner 9, filter screen 10, PC 13, industrial camera 14, recovery device 15, weighing module 16, backlight 17, PLC controller 18.

[0044] The mechanical arm 1 is arranged above the machine-made sand conveyor belt, and takes samples at a preset frequency, and puts the machine-made sand to be tested into the weighing pan 4 .

[0045]The weighing pan 4 is arranged at one end of the weighing handle, and is used for holding samples of the mechanical arm. There is a heating and drying device on the top, which is used to dry and remove water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com