Repairing method of large-section low-voltage single-core flexible cable

A repair method and flexible cable technology, applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems of construction safety and quality cannot be guaranteed, platform bearing capacity is limited, difficult to use, etc., to achieve high construction efficiency, lightweight materials, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

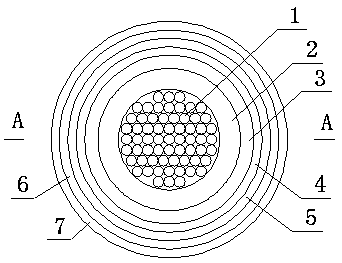

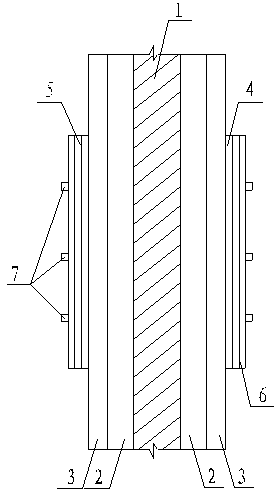

[0028] like figure 1 and figure 2 As shown, a method for repairing a large-section low-voltage single-core flexible cable includes the following steps:

[0029] Step (1), if the insulating layer of the damaged cable is not falling off, use glue with the same chemical composition as the cable insulating layer material to glue the damaged part; if the insulating layer of the damaged part falls off, use a knife to repair the gap, Fill with rubber of the same thickness and material as the insulation layer, and use glue with the same chemical composition as the cable insulation layer material for bonding;

[0030] In step (2), use a high-voltage waterproof insulating rubber self-adhesive tape that can withstand 1.5 times the rated voltage of the cable to be repaired to perform semi-overlapping wrapping on the damaged area, with 4 layers of wrapping, and the wrapping range is 5cm above and below the damaged area;

[0031] Step (3), use electrical PVC insulating tape that can with...

Embodiment 2

[0034] like figure 1 and figure 2 As shown, a method for repairing a large-section low-voltage single-core flexible cable includes the following steps:

[0035] Step (1), if the insulating layer of the damaged cable is not falling off, use glue with the same chemical composition as the cable insulating layer material to glue the damaged part; if the insulating layer of the damaged part falls off, use a knife to repair the gap, Fill with rubber of the same thickness and material as the insulation layer, and use glue with the same chemical composition as the cable insulation layer material for bonding;

[0036] In step (2), use a high-voltage waterproof insulating rubber self-adhesive tape that can withstand 1.5 times the rated voltage level of the cable to be repaired to perform semi-overlapping wrapping on the damaged area, with 3 layers of wrapping, and the wrapping range is 10cm above and below the damaged area;

[0037] Step (3), use electrical PVC insulating tape that c...

Embodiment 3

[0040] like figure 1 and figure 2 As shown, a method for repairing a large-section low-voltage single-core flexible cable includes the following steps:

[0041] Step (1), if the insulating layer of the damaged cable is not falling off, use glue with the same chemical composition as the cable insulating layer material to glue the damaged part; if the insulating layer of the damaged part falls off, use a knife to repair the gap, Fill with rubber of the same thickness and material as the insulation layer, and use glue with the same chemical composition as the cable insulation layer material for bonding;

[0042] In step (2), use a high-voltage waterproof insulating rubber self-adhesive tape that can withstand 1.5 times the rated voltage level of the cable to be repaired to perform semi-overlapping wrapping on the damaged area. Extension 7.5cm;

[0043] Step (3), use electrical PVC insulating tape that can withstand 1.5 times the rated voltage level of the cable to be repaired...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com