System for soil compactness measurement and automatic adjustment of finely prepared land

An automatic adjustment and compactness technology, applied in the direction of measuring device, specific gravity measurement, application, etc., can solve problems affecting soil air permeability, water permeability, fertilizer utilization rate and biological activity, unstable soil compactness, etc., to improve work Performance and adaptability, avoidance of randomness and hysteresis, effects of continuous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

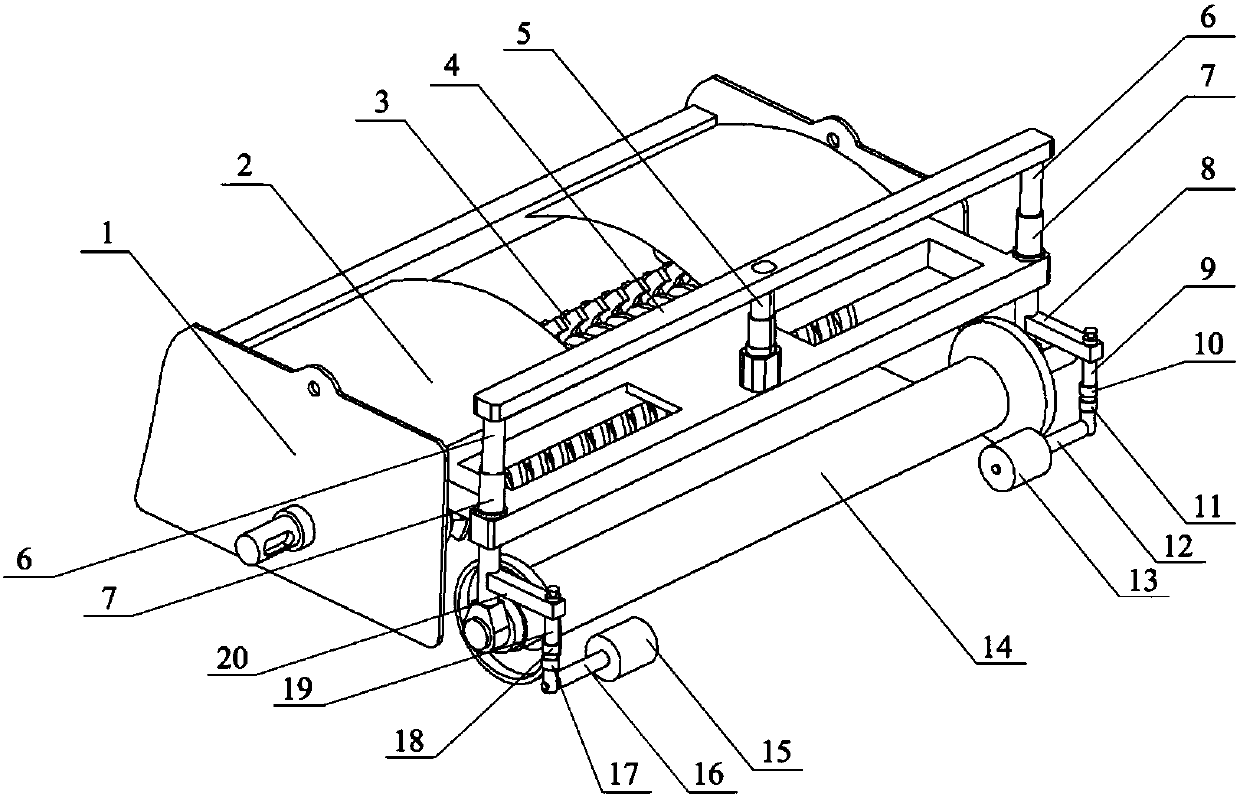

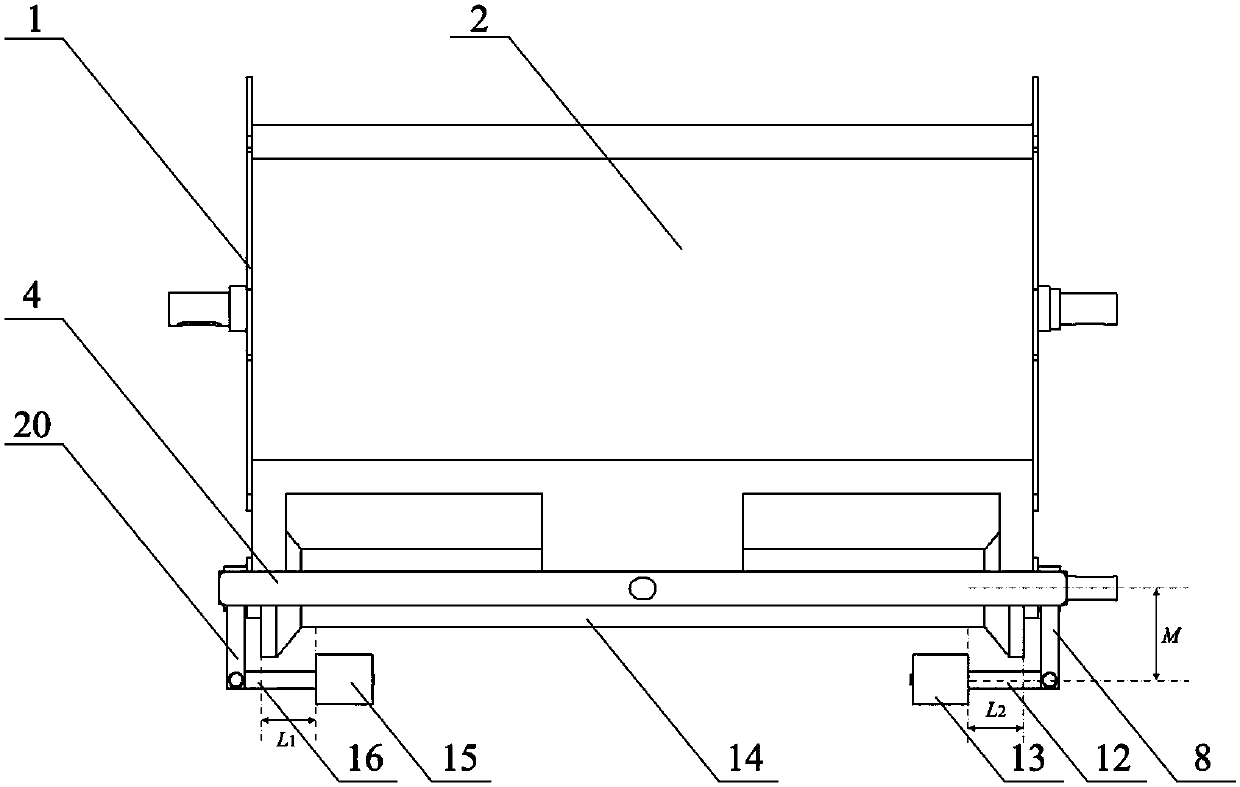

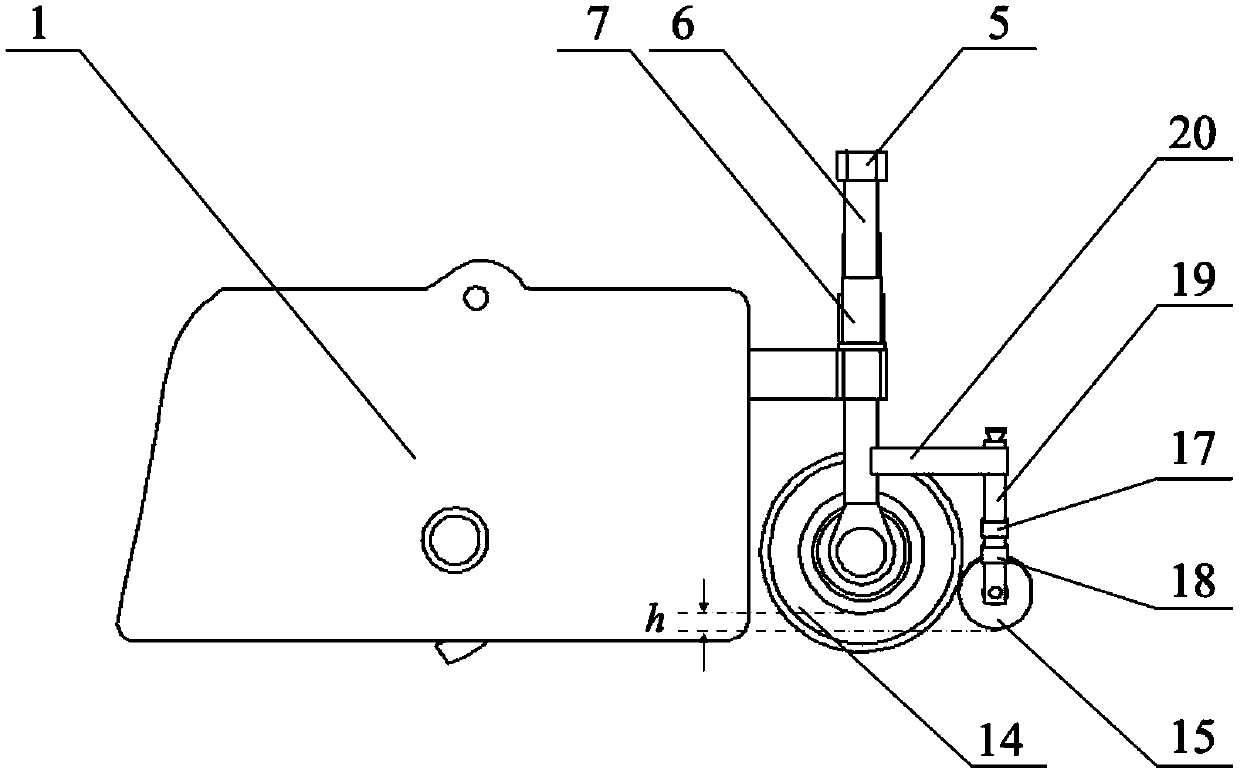

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0031] figure 1Shown is an embodiment of the soil compactness measurement and automatic adjustment system for finishing soil according to the present invention, and the soil compactness measurement and automatic adjustment system for finishing soil is installed at the tail of the frame 1 of the finishing machine; The front part of the frame 1 is horizontally installed with a rotary tillage and crushed soil component 3 through a bearing, and a cover plate 2 is installed above the rotary tillage and crushed soil component 3 .

[0032] The soil compactness measurement and automatic adjustment system for finishing ground includes a soil compactness measurement mechanism, a compaction depth automatic adjustment mechanism and a controller 21 .

[0033] Described soil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com