Preparation method and device of difluoroethanol

A technology of difluoroethanol and difluoroethane, which is applied in the field of preparation of difluoroethanol, can solve the problems of difficult treatment, long process route, and many solid wastes, and achieve mild reaction conditions, no pollution to the environment, and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

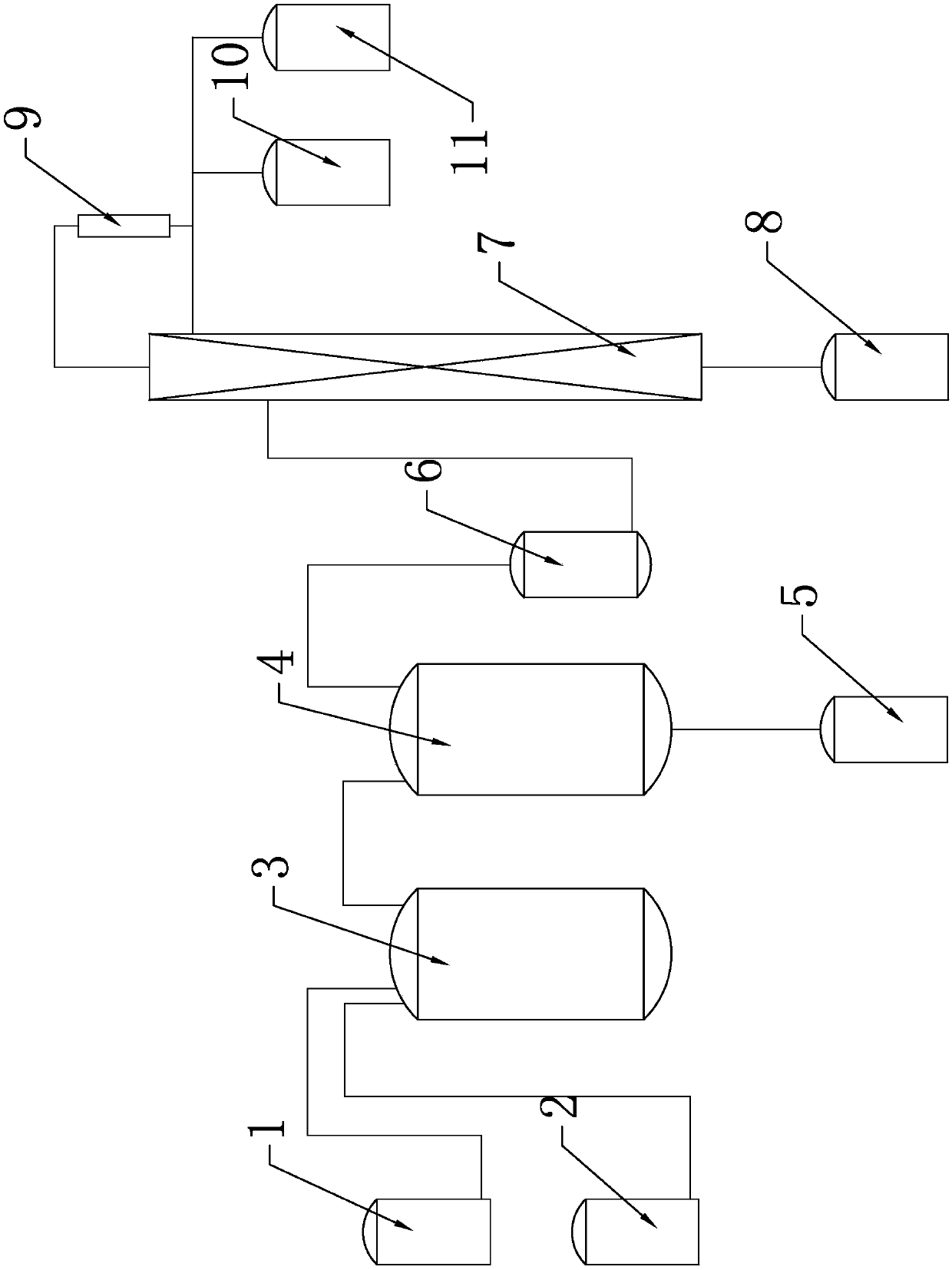

[0025] The preparation method of this difluoroethanol comprises the steps:

[0026] (1) Add 600g of solvent and 100g of potassium hydroxide in a 1.5L reactor to react under stirring, the reaction temperature is 140°C, and the reaction time is 0.5 hours;

[0027] (2) After the reaction in step (1) is completed, slowly add 300 g of 2-chloro-1,1-difluoroethane to the reactor at a flow rate of 100 mL / h, the reaction temperature is 200 ° C, the reaction time is 10 hours, and then the The product is sequentially sent to the rough steamer 4 and the rectification tower 7 for separation to obtain 2,2-difluoroethanol.

[0028] The reaction of step (1) and step (2) is carried out in an inert gas nitrogen, and the stirring speed is controlled at 600 rpm.

[0029] The water of 5%~10% potassium hydroxide weight is added in the reaction process of step (1) and step (2) or before reaction starts.

[0030] The solvent is γ-butyrolactone.

[0031] 2-Chloro-1,1-difluoroethane storage tank 1 a...

Embodiment 2

[0036] The difference between this example and Example 1 is: add 600g of solvent and 100g of potassium hydroxide to a 1.5L reactor, control the stirring speed at 600r / min, the temperature at 160°C, and react for 1.5h; Add 300 g of 2-chloro-1,1-difluoroethane, control the temperature at 250° C., and react for 10 hours. After the reaction is completed, difluoroethanol is separated and collected.

Embodiment 3

[0038] The difference between this example and Example 1 is: add 1000g of solvent, 100g of potassium hydroxide and 10g of water into a 1.5L reactor, control the stirring speed at 400r / min, the temperature at 130°C, and react for 1h; 300 g of 2-chloro-1,1-difluoroethane was injected at a flow rate of 2-chloro-1,1-difluoroethane, the temperature was controlled at 190° C., and the reaction was carried out for 8 hours. After the reaction was completed, difluoroethanol was separated and collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com