Polishing device for inner surface of straight pipe

A technology of inner surface polishing and straight pipe, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding workpiece supports, etc., which can solve the problem of deep scratches on the surface, difficult control of surface quality, and single trajectory of rigidity improvement and other problems, to achieve the effect of compact structure, convenient installation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

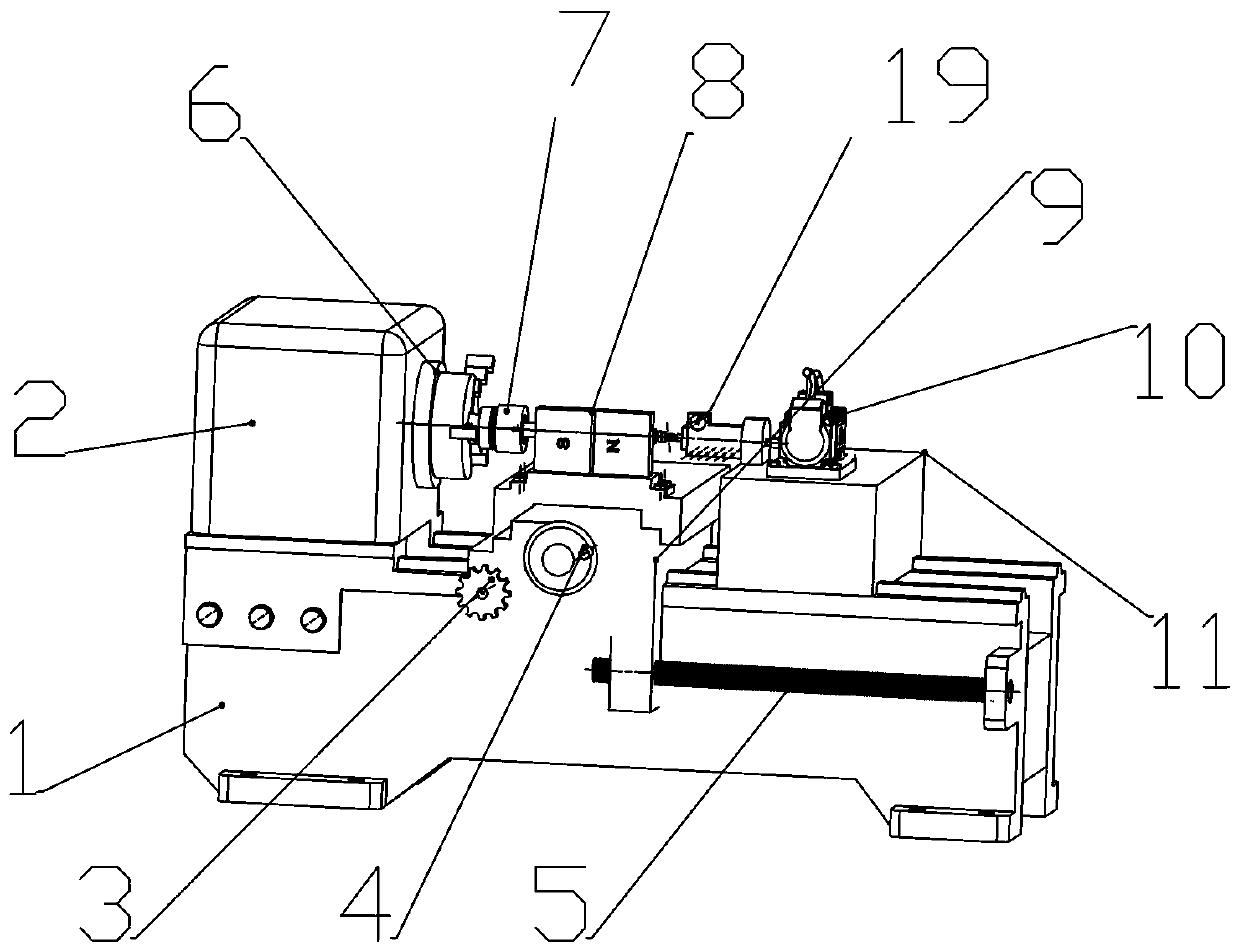

[0023] like Figure 1-8 As shown, the straight pipe inner surface polishing device of the present invention includes a machine tool overall frame, a three-jaw chuck 6 arranged on the machine tool overall frame, the described machine tool overall frame includes a bed 1, and the machine tool is arranged on the machine bed 1 Spindle box 2, leading screw 5 and tailstock 11 are characterized in that a clamping processing part, a guide part and a magnetic pole part are arranged on the overall frame of the machine tool,

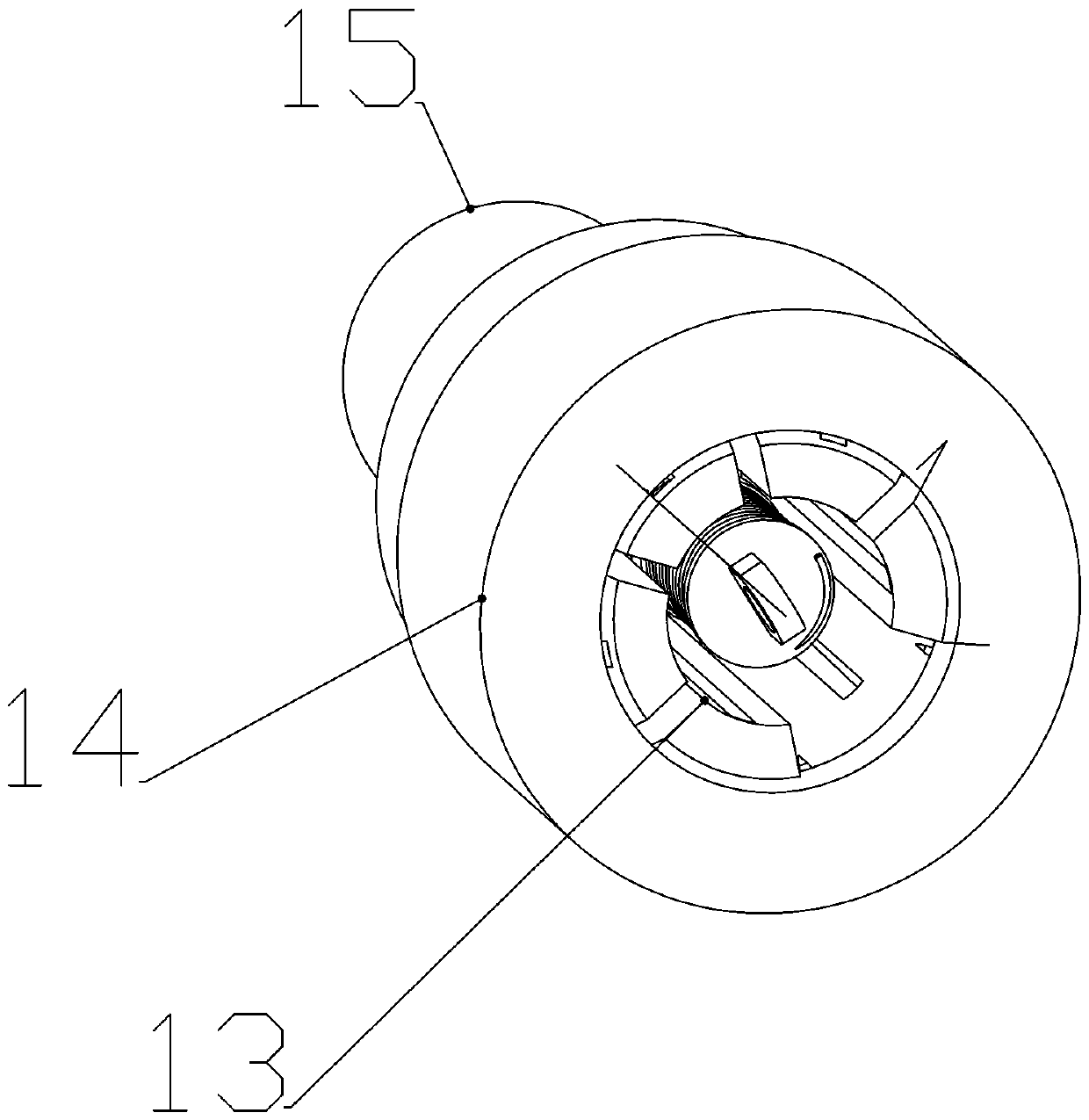

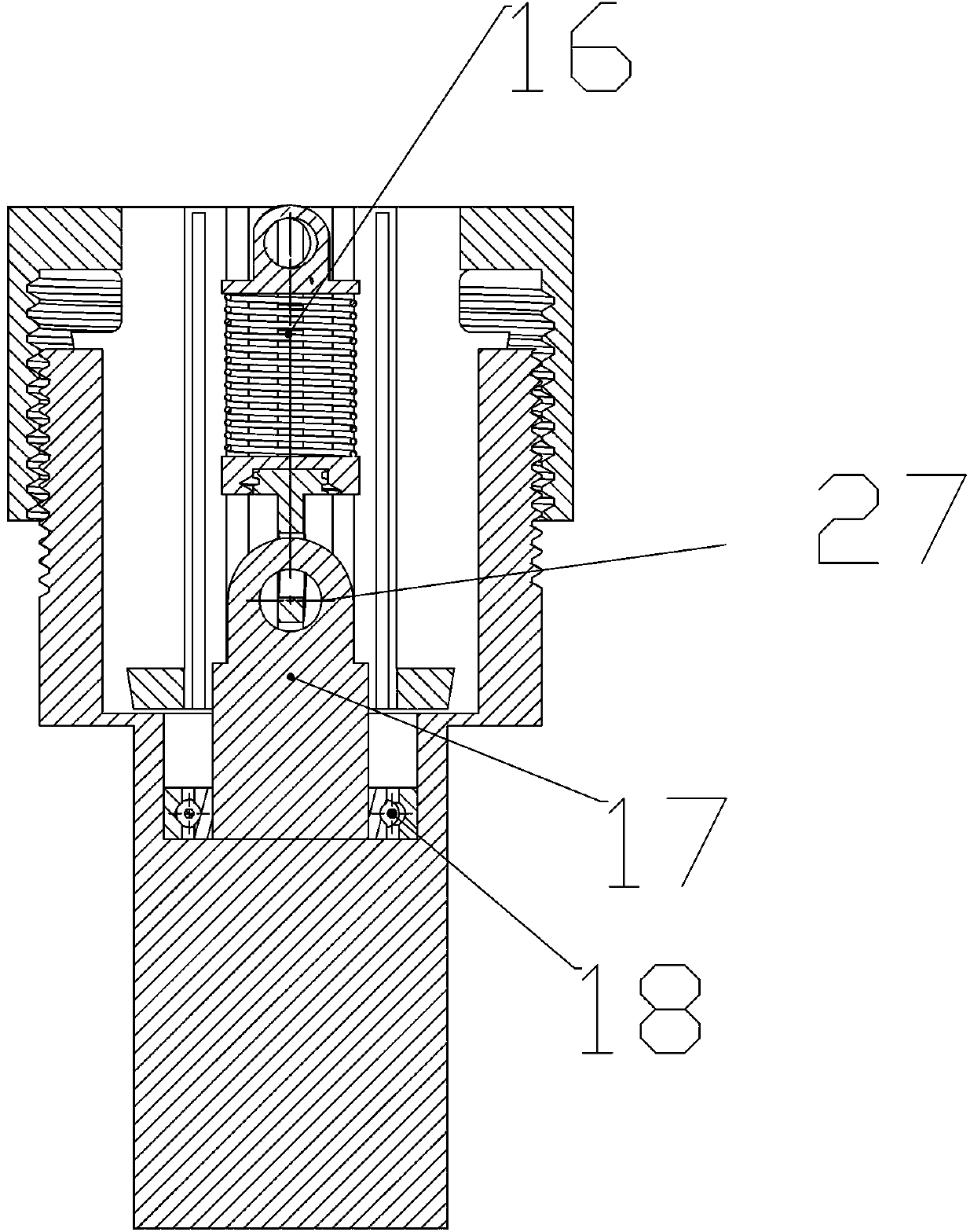

[0024] The clamping part includes a collet 7 clamped on the three-jaw chuck 6, and the collet 7 includes a collet holder 15 clamped on the three-jaw chuck 6, embedded in the collet The collet main body 13 in the collet holder 15, the collet cover 14 threadedly connected with the collet main body 13, the bearing I18 embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com