Grouting material for highways and tunnels and preparation method thereof

A technology for grouting materials and culverts, which is applied in the field of highway culvert grouting materials and its production, which can solve the problems of long setting time, large shrinkage, and low flexural strength, and achieve reasonable filling performance, saving water for grouting, and reducing porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Anhydrite, limestone, and sulfur-aluminum clinker are crushed separately, passed through a 60-mesh sieve, and 15kg of anhydrite powder, 10kg of limestone, and 70kg of sulfur-aluminum clinker are added to a grinder and ground until the specific surface area is 450cm2 / g. Stop grinding, transfer to a homogenizer, homogenize for 15 minutes, transfer to a high-speed mixer, add 100kg of aggregate (aggregate is a combination of quartz sand with a weight ratio of 1: ironmaking waste slag: 2 calcium carbonate slag: 3) , water reducer polycarboxylate water reducer 0.4kg, anti-sedimentation agent methylpropanesulfonic acid polymer 0.07kg, defoamer 0.1kg and anti-crack fiber organosilicon compound polysiloxane 0.3kg, mix uniformly to obtain sulfur Aluminate-based high-strength grouting material.

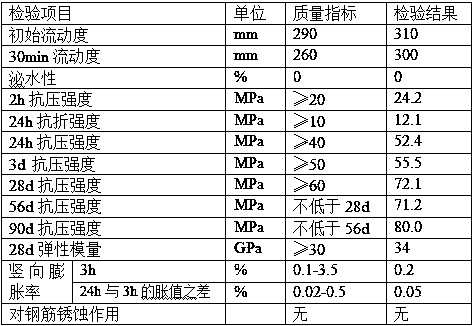

[0039] Table 1 is the performance test result of embodiment 1 gained product:

[0040] Table 1:

[0041]

Embodiment 2

[0044] Table 2 is the performance test result of the product obtained in embodiment 2:

[0045] Table 2:

[0046]

[0047] It can be seen from the above that the products of this application all meet the industry standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com