A method for preparing polyvinyl alcohol film using multiple coating film forming process

A technology of polyvinyl alcohol film and polyvinyl alcohol, which is applied in the field of casting polyvinyl alcohol film to achieve the effects of increasing drying speed, improving film forming efficiency and stabilizing coating accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

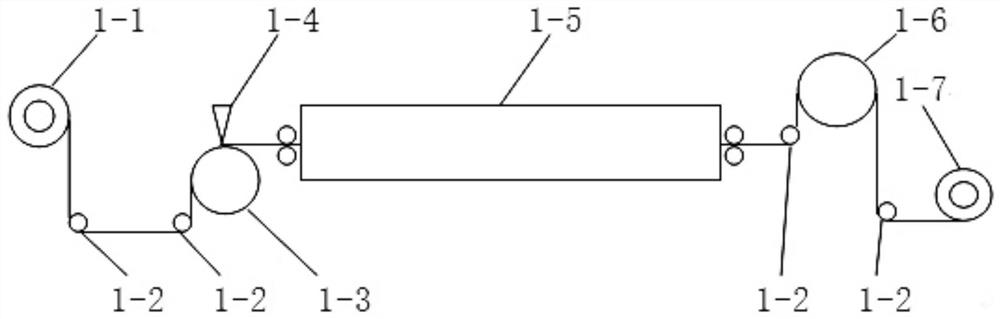

[0037] The polyvinyl alcohol film was prepared using a multiple-coating film-forming process, using 2 figure 1 The process modules shown are connected in series for 2 times of precision coating and film production, which specifically includes the following steps:

[0038] (1) Through the precision coating die, the polyvinyl alcohol aqueous solution (solid content of 18%) is precisely coated on the PET film (thickness is 30μm, width is 1200mm), and the two sets of process modules are connected in series to form the film thickness. Both are 10µm (the thickness is 20µm after the secondary coating is formed), and the coating width is 1200mm; it is dried through the hot air drying channel, and the temperature is controlled in 6 sections for drying. 80 / 100 / 120 / 140 / 160 / 120°C, cool down to 30°C after drying;

[0039] The conveying speed of the PET film is all 50m / min, and finally a polyvinyl alcohol film with a thickness of 20µm is formed on the PET film; the moisture content of the ...

Embodiment 2

[0043] The polyvinyl alcohol film was prepared using a multiple-coating film-forming process, using 3 figure 1 The process modules shown are connected in series for 3 times of precision coating and film production, which specifically includes the following steps:

[0044] (1) Through the precision coating die, the polyvinyl alcohol aqueous solution (solid content of 15%) is precisely coated on the PET film (thickness is 60μm, width is 1500mm), and the thickness of the precision coating film is 10μm (after The thickness of the film after three times of coating is 30µm), and the coating width is 1500mm; it is dried through the hot air drying channel, and the temperature is controlled in 6 sections for drying. According to the order of introduction, the first and third process modules are divided into The temperature of the segment is 90 / 105 / 125 / 145 / 165 / 120℃, the temperature of the second process module is 100 / 120 / 140 / 150 / 160 / 120℃, and it is cooled to 28℃ after drying;

[0045] ...

Embodiment 3

[0049] The polyvinyl alcohol film was prepared using a multiple coating film-forming process, using 1 figure 1 The process module shown is repeated 3 times for precision coating and film production, which specifically includes the following steps:

[0050] (1) Through the precision coating die, the polyvinyl alcohol aqueous solution (solid content of 25%) is precisely coated on the PET film (thickness is 100μm, width is 300mm), and the thickness of the precision coating film is 15μm (after three times. The thickness of the film after coating is 45µm), and the coating width is 300mm; it is dried through the hot air drying channel, and the temperature is controlled in 6 sections for drying. / 120℃, cooled to 25℃ after drying;

[0051] (2) Repeat the operation of step (1) twice, the thickness of the coating film is 15 μm, and the other conditions are the same;

[0052] The conveying speed of the PET film is 30m / min, and finally a polyvinyl alcohol film with a thickness of 45µm i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com