Ceramic-simulating flame-retardant PET/ABS (polyethylene terephthalate/acrylonitrile-butadienes-styrene) resin composition and preparation method thereof

A technology of ABS resin and ceramic imitation, which is applied in the field of ceramic imitation flame-retardant PET/ABS resin composition and its preparation, can solve the problems of difficult recycling, fragility, complex process, etc., and achieve good weather resistance, good impact resistance, good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

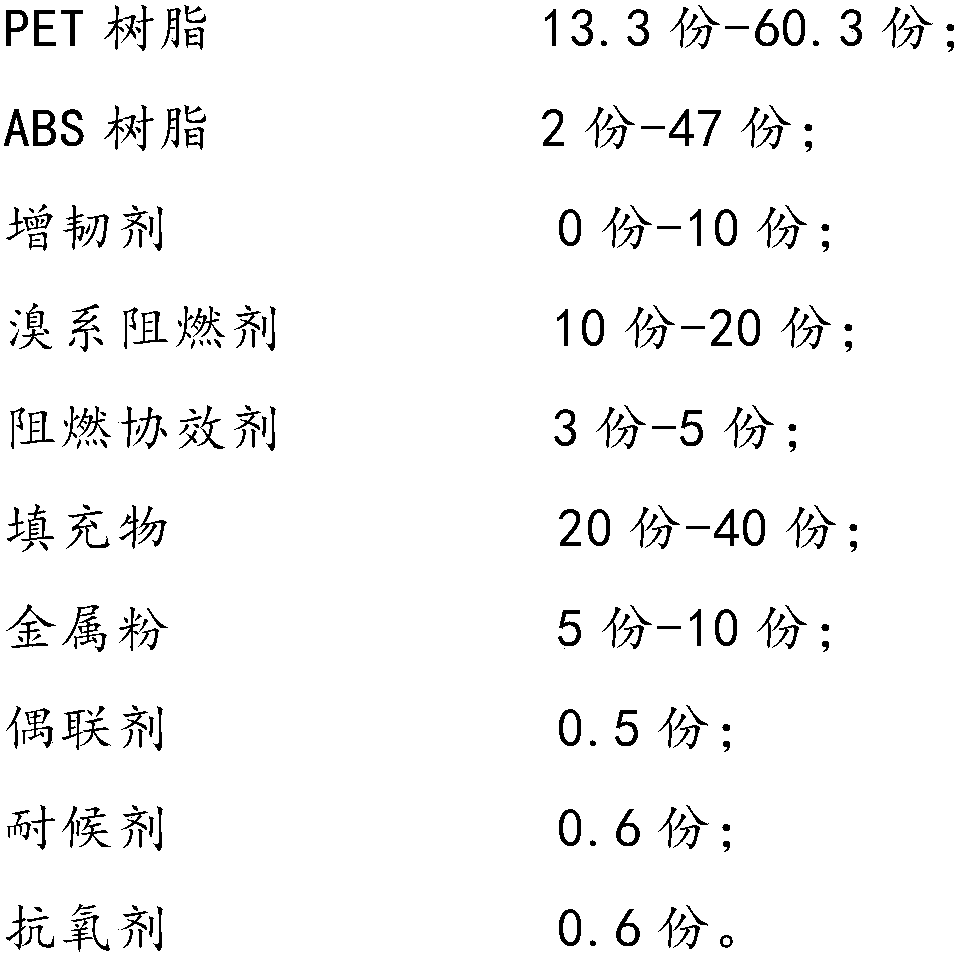

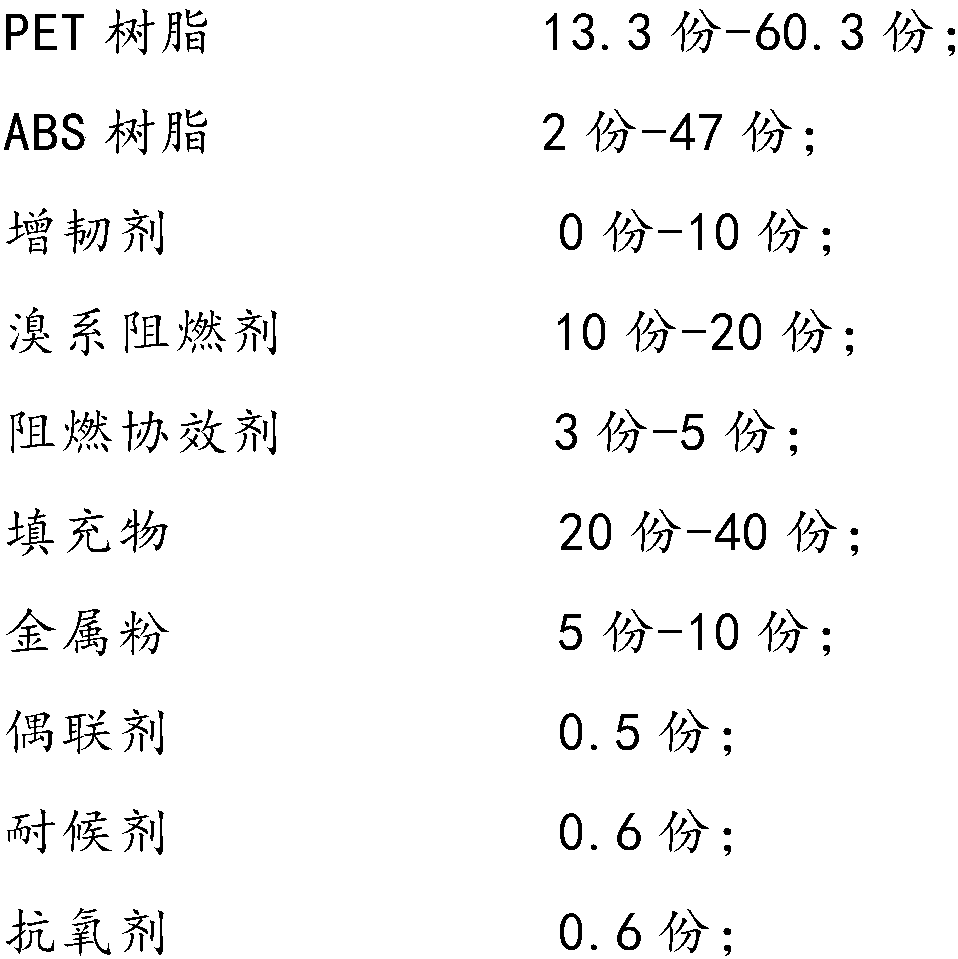

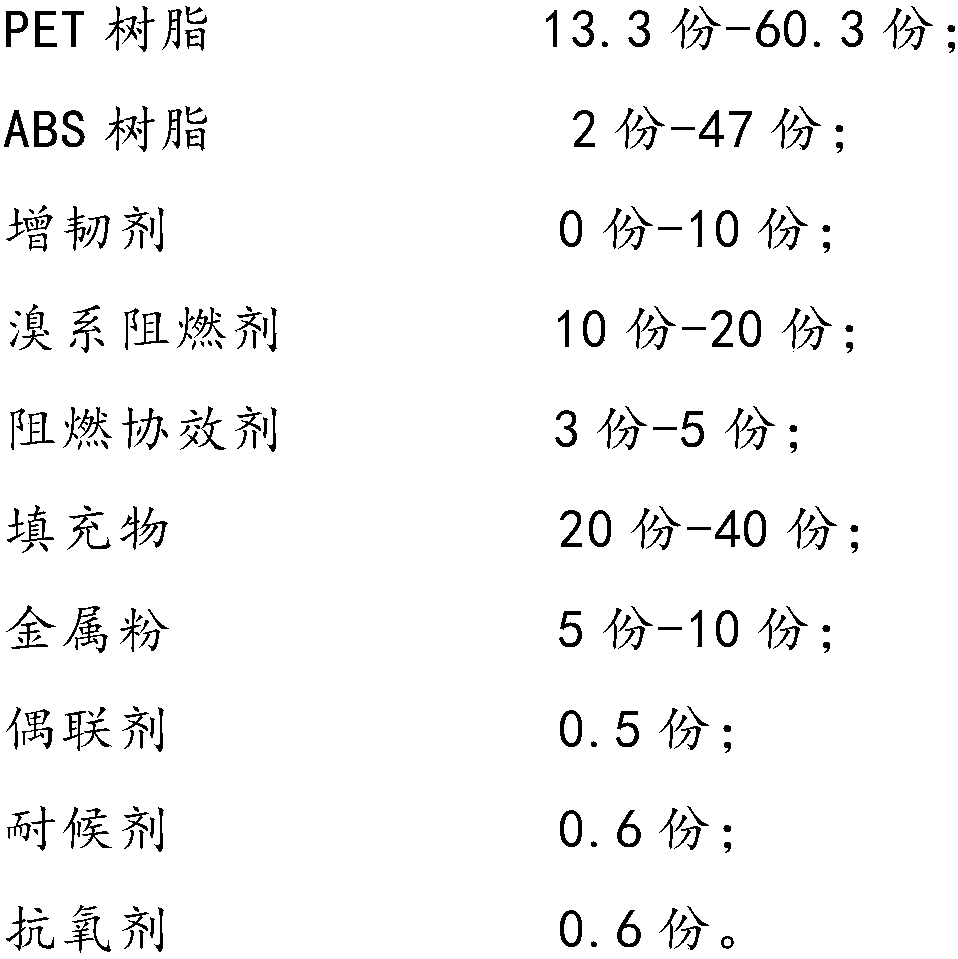

Method used

Image

Examples

Embodiment 1

[0044] Mix AB-3000N1, HYFE-300, Z-6040 in a high-speed mixer at room temperature for 5-10 minutes; then mix PET BG80, ABS PA757, PBS-64HW, S-05N, TINUVIN 327, CHIMASSORB944, Irganox 1010 , Irganox 168 is mixed in a high-speed mixer, and then extruded in a twin-screw extruder. The processing conditions are: the temperature of the first zone is 240°C, the temperature of the second zone is 245°C, the temperature of the third zone is 250°C, the temperature of the fourth zone is 250°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 255°C, the temperature of the seventh zone is 255°C, and the temperature of the eighth zone is 255°C ℃, the temperature in the ninth zone is 245 ℃; the speed of the host is 350 rpm.

Embodiment 2

[0046]Mix AB-3000N1, HYFE-300, Z-6040 in a high-speed mixer at room temperature for 5-10 minutes; then mix PET BG80, PBS-64HW, S-05N, TINUVIN 327, CHIMASSORB 944, Irganox 1010, Irganox 168 into a high-speed mixer for mixing, and then extruded in a twin-screw extruder. The processing conditions are: the temperature of the first zone is 240°C, the temperature of the second zone is 245°C, the temperature of the third zone is 250°C, the temperature of the fourth zone is 250°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 255°C, the temperature of the seventh zone is 255°C, and the temperature of the eighth zone is 255°C °C, the temperature in the ninth zone is 245 °C; the speed of the host is 350 rpm.

Embodiment 3

[0048] Mix AB-3000N1, HYFE-300, Z-6040 in a high-speed mixer at room temperature for 5-10 minutes; then mix PET BG80, PTW, PBS-64HW, S-05N, TINUVIN 327, CHIMASSORB 944, Irganox 1010 , Irganox168 is added to a high-speed mixer for mixing, and then extruded in a twin-screw extruder. The processing conditions are: the temperature of the first zone is 240°C, the temperature of the second zone is 245°C, the temperature of the third zone is 250°C, the temperature of the fourth zone is 250°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 255°C, the temperature of the seventh zone is 255°C, and the temperature of the eighth zone is 255°C °C, the temperature in the ninth zone is 245 °C; the speed of the host is 350 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com