Nanosphere emulsion reaction vessel with condensation function

A technology of nano-microspheres and reactors, which is applied in chemical/physical/physical-chemical fixed reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, and can solve the problem of fast cooling without affecting nano-microspheres Emulsion and other problems, to avoid granule force, reduce loss, and facilitate observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

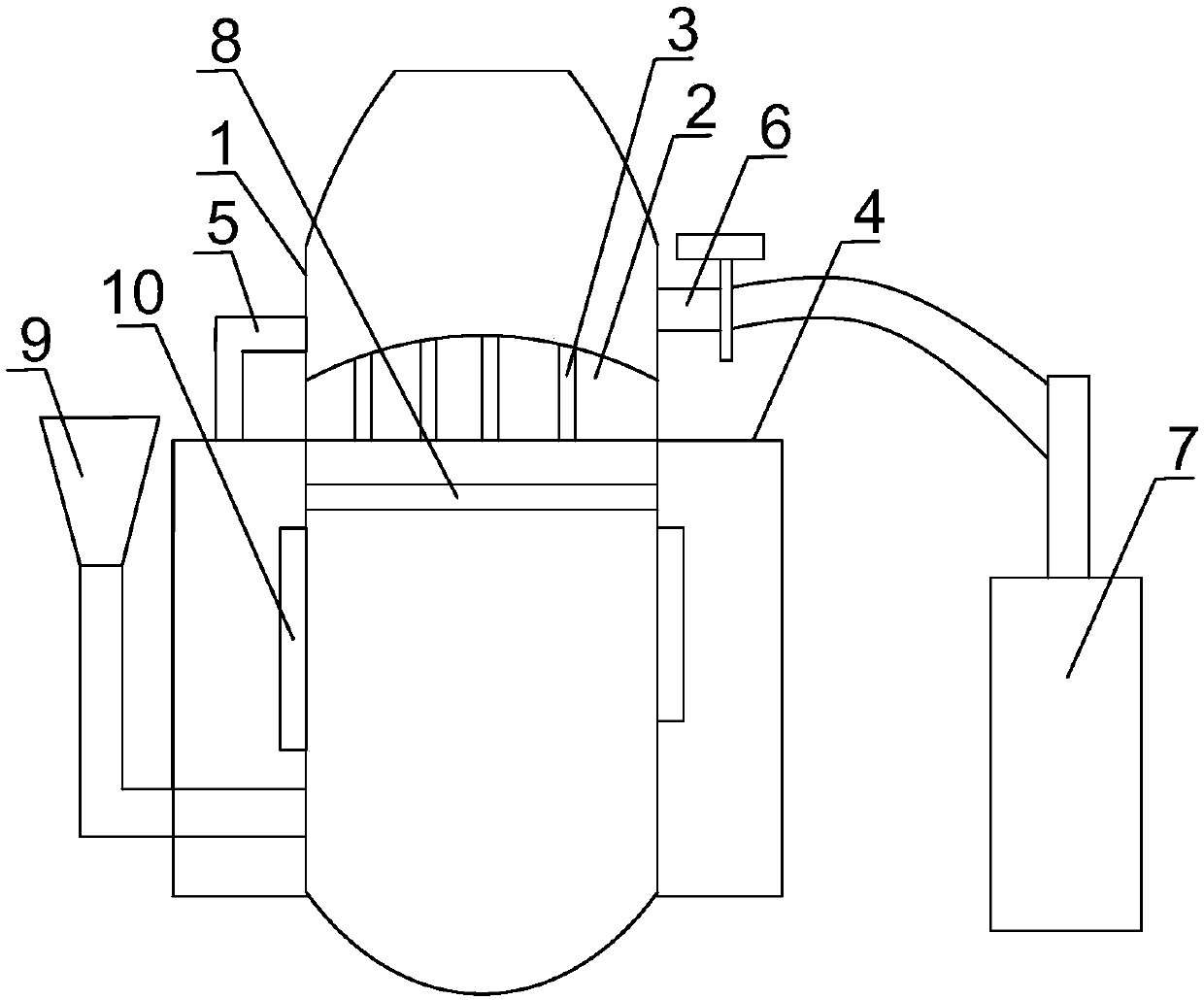

[0023] like figure 1 As shown, the nano-microsphere emulsion reaction kettle with condensation function of the present invention comprises a hollow kettle body 1, and a deflector 2 is arranged inside the kettle body 1, and the inside of the kettle body 1 is divided into upper and lower parts by the deflector plate 2. , the lower two independent cavities, the nano-microsphere emulsion is located in the cavity below the deflector 2, the deflector 2 is provided with a plurality of through holes 3, and the outer side of the kettle body 1 below the deflector 2 is provided with a jacket 4. Both the top and the bottom of the jacket 4 are sealed and connected with the kettle body 1, and the top of the jacket 4 is connected with an air outlet pipe 5, and the air outlet pipe 5 connects the cavity above the deflector 2 with the jacket 4 and the outer wall of the kettle body 1. The cavity between them is connected, and the kettle body 1 is provided with an inlet pipe 6 communicating with ...

Embodiment 2

[0026] Based on Example 1, the diameter of the through hole 3 is 0.3mm-0.5mm. The aperture of the through hole affects the amount of cold air entering the cavity below the deflector. Using a through hole of 0.3mm-0.5mm can not only continuously pass the cold air into the cavity below the deflector, but also avoid the impact of cold air on the nanosphere emulsion. Generate granule force and keep the nano microsphere emulsion in a static state.

Embodiment 3

[0028] Based on the above embodiment, the air filter cotton 8 is arranged under the deflector 2 , and the upper surface of the air filter cotton 8 is adhered with a polymer water-absorbing resin.

[0029] The polymer water-absorbing resin can absorb water droplets dripping from the through holes, and the air filter cotton has the function of filtering cold air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com