Lanthanum-doped metal organic framework material as well as preparation method and application thereof

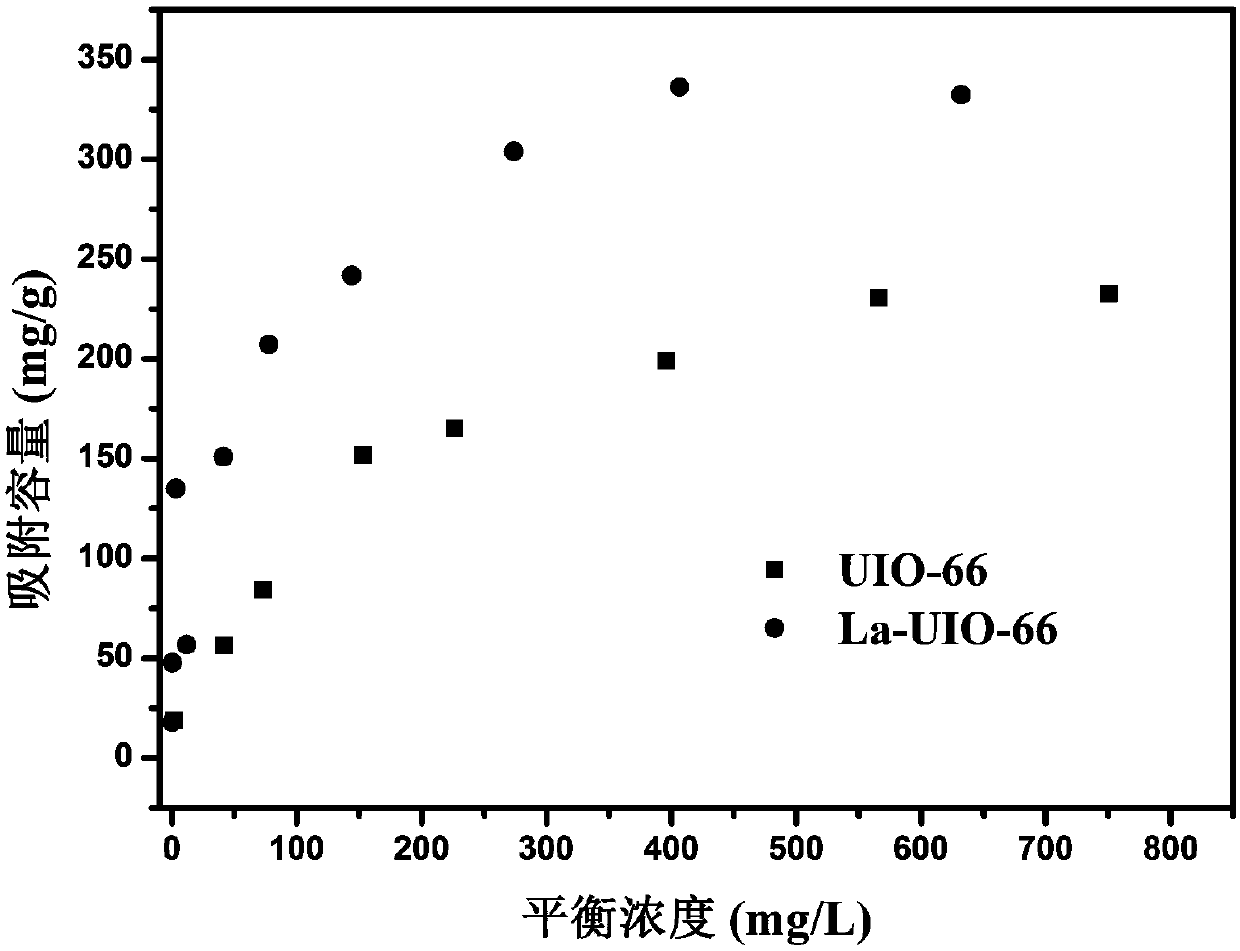

A metal-organic framework and framework material technology, which is applied in the field of lanthanum-doped metal-organic framework materials and its preparation, can solve the problems of limited adsorption sites and phosphate adsorption capacity, and achieve easy operation, excellent recycling performance, The effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention provides a preparation method of lanthanum-doped metal organic framework material, which comprises the following steps:

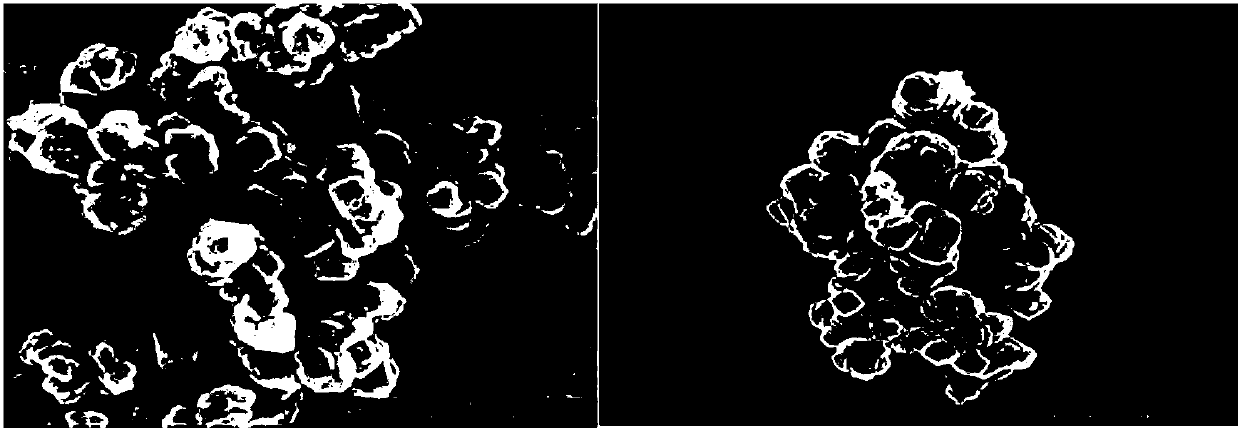

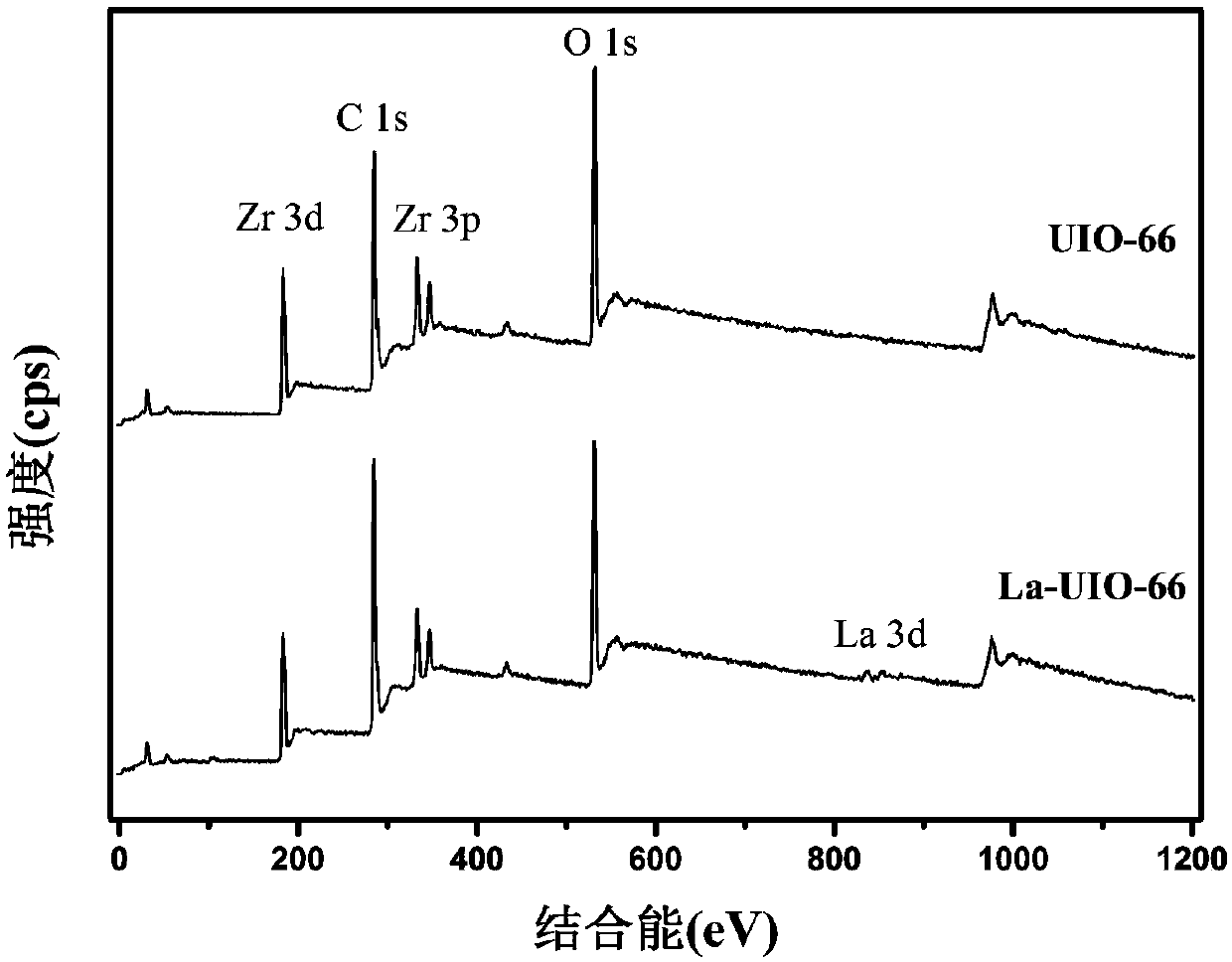

[0025] (1) Crosslinking reaction of zirconium tetrachloride and terephthalic acid in N,N dimethylformamide to obtain a basic framework material;

[0026] (2) Reacting the basic framework material and lanthanum chloride heptahydrate to obtain a lanthanum-doped metal organic framework material.

[0027] In the preparation method of the present invention, all raw materials used are commercially available products that are well known to those skilled in the art, and will not be described in detail below.

[0028] In the present invention, zirconium tetrachloride and terephthalic acid are reacted in N,N dimethylformamide to obtain a basic framework material. In the present invention, the ratio of the amount of the zirconium tetrachloride and terephthalic acid is preferably (1 to 3):1, more preferably (1 to 2):1; the zirconium tetrachloride ...

Embodiment 1

[0044] a. Dissolve 4mmol of zirconium chloride and 4mmol of terephthalic acid in 100ml of N,N-dimethylformamide, sonicate at 70Hz for 30min to fully dissolve the reaction, and obtain the primary basic framework material (primary UIO-66) The uniformly mixed a solution;

[0045] b. Weigh 1.41 mmol of lanthanum chloride heptahydrate and add it to the solution a, and then perform ultrasonic treatment at a frequency of 70 Hz for 30 minutes to obtain a uniformly mixed solution b;

[0046] c. Transfer solution b to an autoclave and react in a high temperature environment of 120°C for 48 hours;

[0047] d. Separate the product through a centrifuge, first wash with methanol and acetonitrile along with the product, then wash with deionized water, and finally dry in a vacuum at 30°C for a total of 12 hours to obtain La-UIO-66.

Embodiment 2

[0049] a. Dissolve 8mmol of zirconium chloride and 4mmol of terephthalic acid in 100ml of N,N-dimethylformamide, sonicate at 70Hz for 30min to fully dissolve the reaction, and obtain the primary basic framework material (UIO-66) A uniformly mixed solution;

[0050] b. Weigh 8mmol of lanthanum chloride heptahydrate and add it to solution a, and then perform ultrasonic treatment at a frequency of 70 Hz for 30 minutes to obtain a uniformly mixed solution b;

[0051] c. Transfer solution b to an autoclave and react for 48h in a high temperature environment of 115°C;

[0052] d. Separate the product through a centrifuge, first wash with methanol and acetonitrile along with the product, then wash with deionized water, and finally dry in a vacuum at 30°C for a total of 12 hours to obtain La-UIO-66.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com