A self-cleaning starlight mirror glass film structure for vehicles and its preparation process

A glass film, star mirror technology, used in vehicle parts, synthetic resin layered products, transportation and packaging, etc., can solve the problems of small lens field of view, inability to expand the field of view, unclear reversing audio and video, and achieve good glue-free Adsorption, good cleaning effect, the effect of expanding the field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

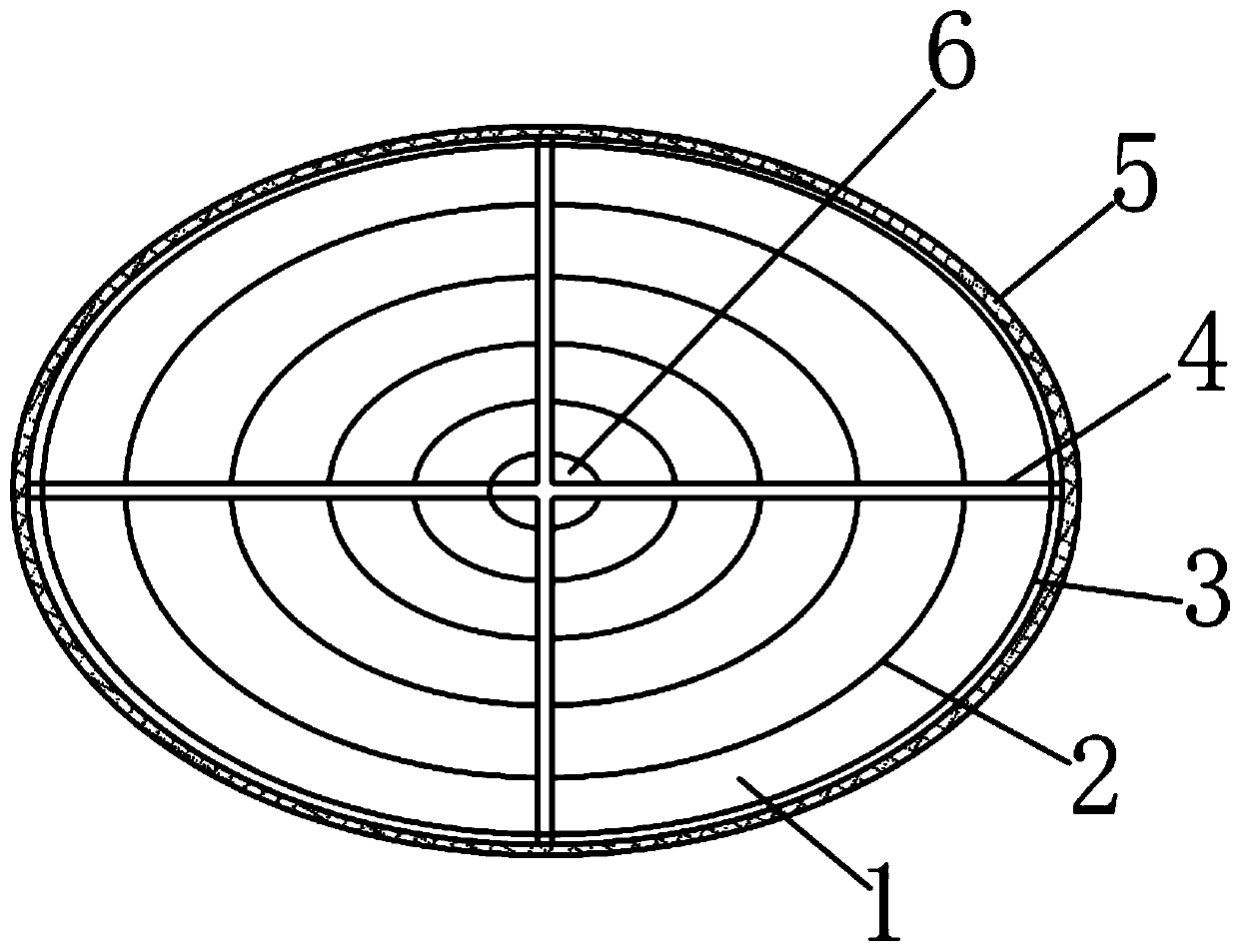

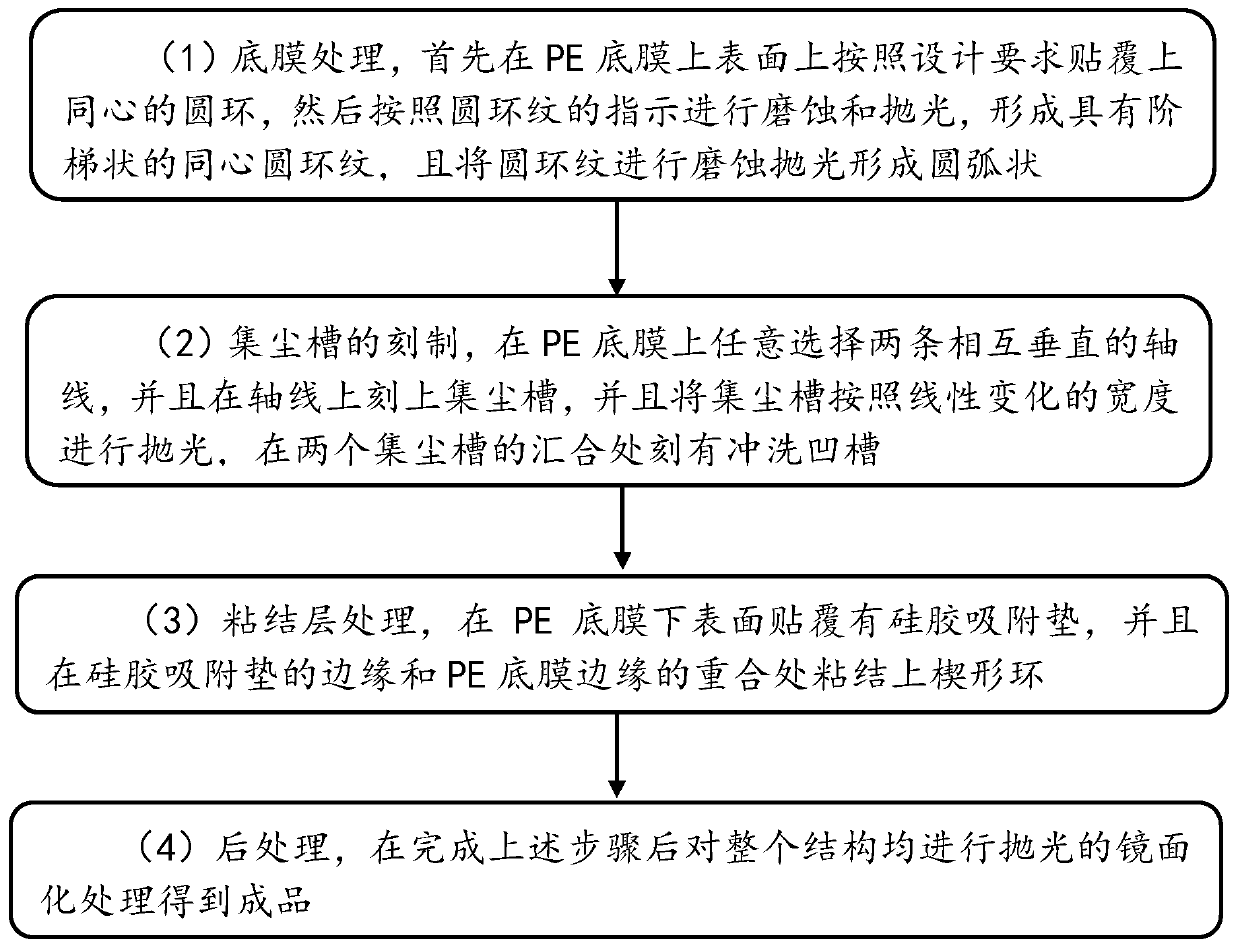

[0019] Such as figure 1 As shown, a self-cleaning star light mirror glass film structure for vehicles includes a PE base film 1, and the upper surface of the PE base film 1 is fixedly covered with several groups of concentric rings 2, and on the lower surface of the PE base film 1 It is fixed and covered with a silica gel adsorption pad 3, and the thickness of the PE backing film 1 decreases in a stepwise manner from the inner side to the outer edge in the order of the rings, and the PE backing film 1 is polished and flattened to a circle at the place where the thickness decreases. Arc-shaped, and on the upper surface of the PE base film 1, there are dust collection grooves 4 along two mutually perpendicular axes, and the two dust collection grooves 4 intersect at the center of the PE base film 1.

[0020] Preferably, a wedge-shaped ring 5 is fixedly installed on the outer edge of the PE bottom film 1, and the thickness of the wedge-shaped ring 5 gradually decreases from the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com