Oil heater stacking system and control method thereof

A palletizing system and oiling technology, which is applied to the stacking of objects, the depalletizing of objects, and the objects on conveyors, etc., can solve the problems of inability to realize glue coating, sealing and palletizing of oily sheets, and reduce the labor intensity of workers and labor costs, high palletizing efficiency, and the effect of improving the automation safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

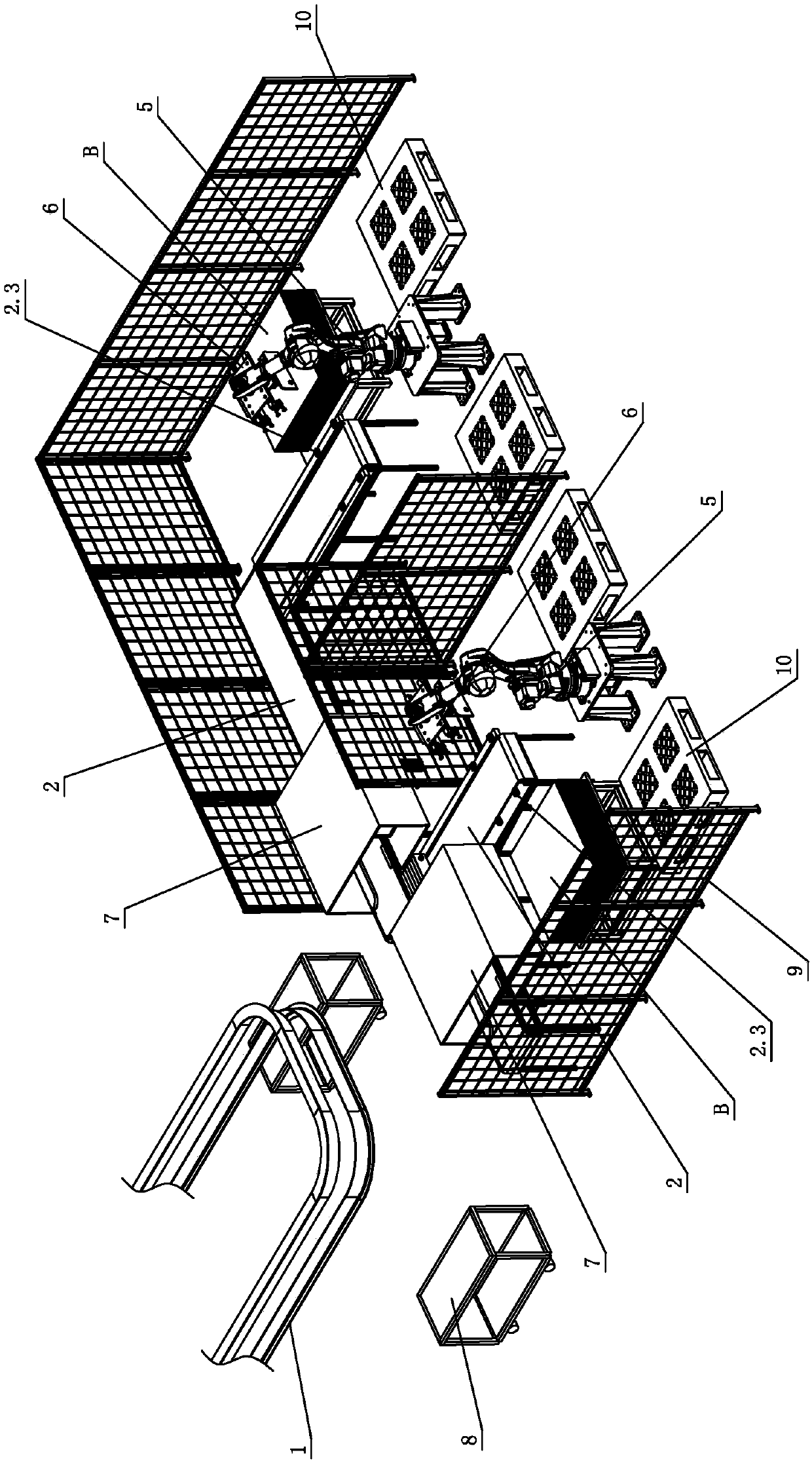

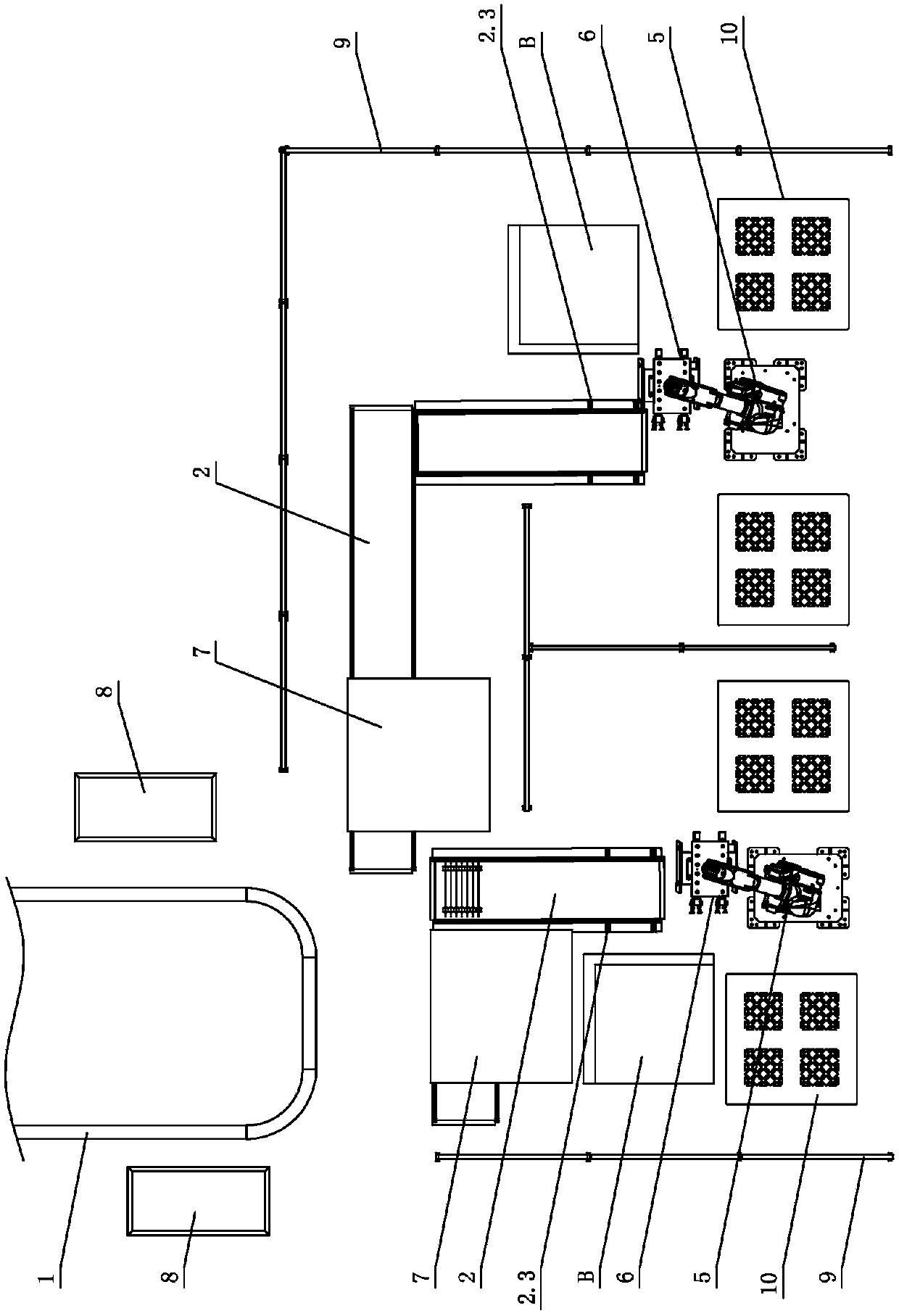

[0038] see Figure 1-Figure 9 , the oil palletizing system, including

[0039] Suspension line 1, used for suspending incoming materials to oil tank Y;

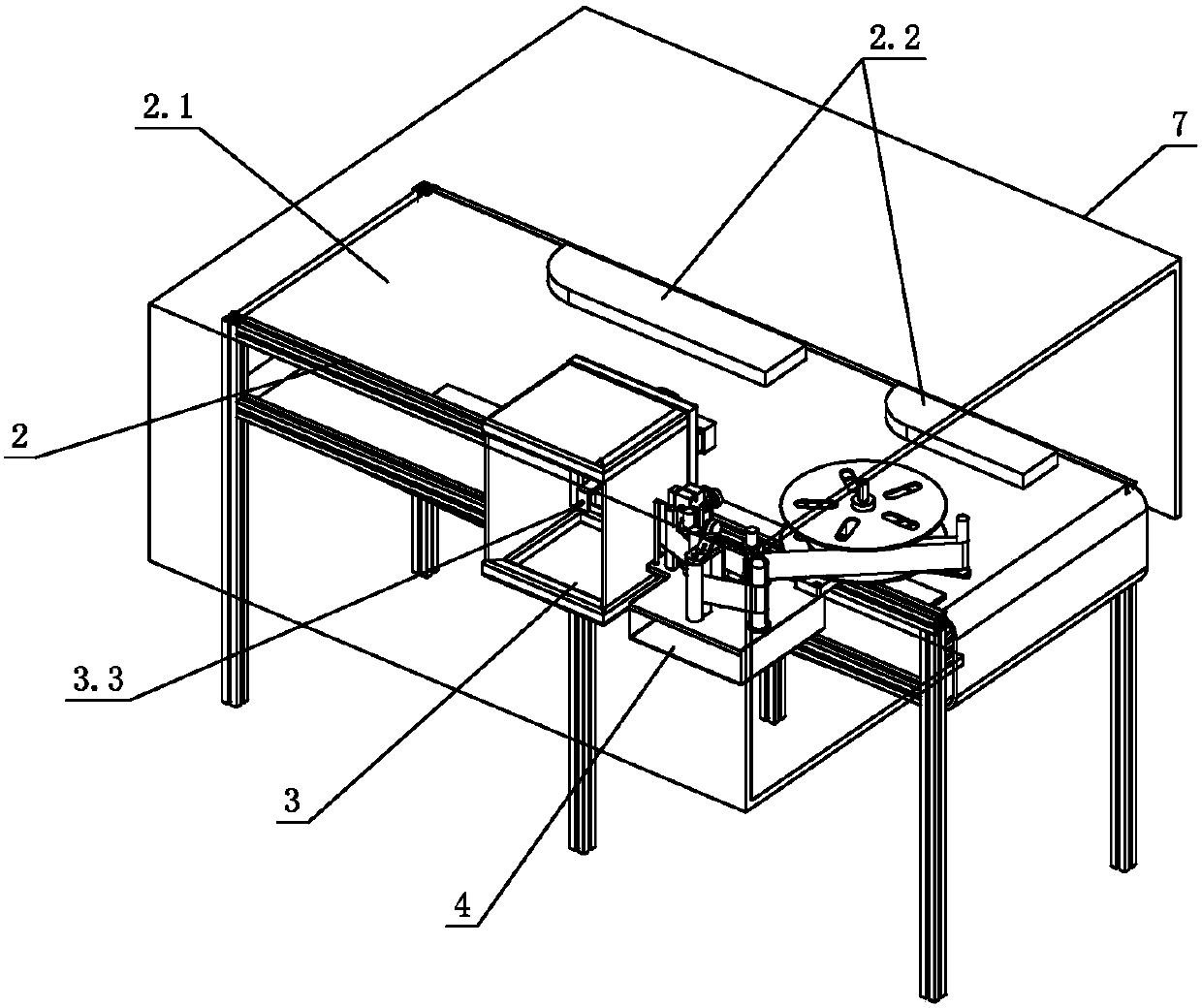

[0040] Two sets of conveying assemblies 2 are used to transfer oil Y from the loading station to the clamping station;

[0041] Two sets of gluing assemblies 3 are used for gluing the grease Y;

[0042] Two sets of sealing assemblies 4 are used to seal the grease Y;

[0043] Two robots 5 stack the oil Y and place the partition B through the dual-purpose fixture 6;

[0044] Two defective product placement tables 8 are used to display the screened out defective products;

[0045] Guardrail 9, used to separate equipment and systems to improve safety;

[0046] Four palletizing trays 10 are used for Y-palletizing of oil, which is convenient for overall handling;

[0047] Among them, the defective pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap