Hot bending apparatus for glass

A glass and equipment technology, applied in the field of glass hot bending equipment, can solve the problems of high heating energy consumption, fast heat dissipation, and inaccurate temperature control of heating tubes, and achieve the effects of reducing mold loss, improving work efficiency, and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

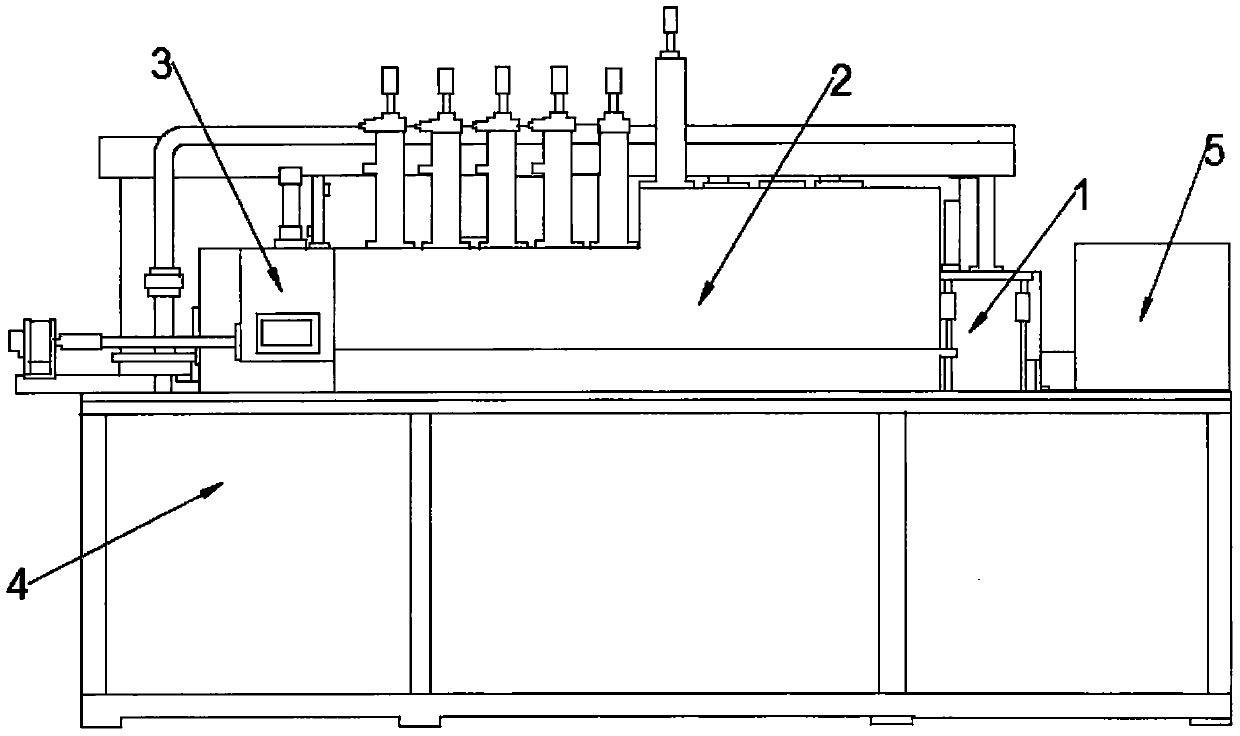

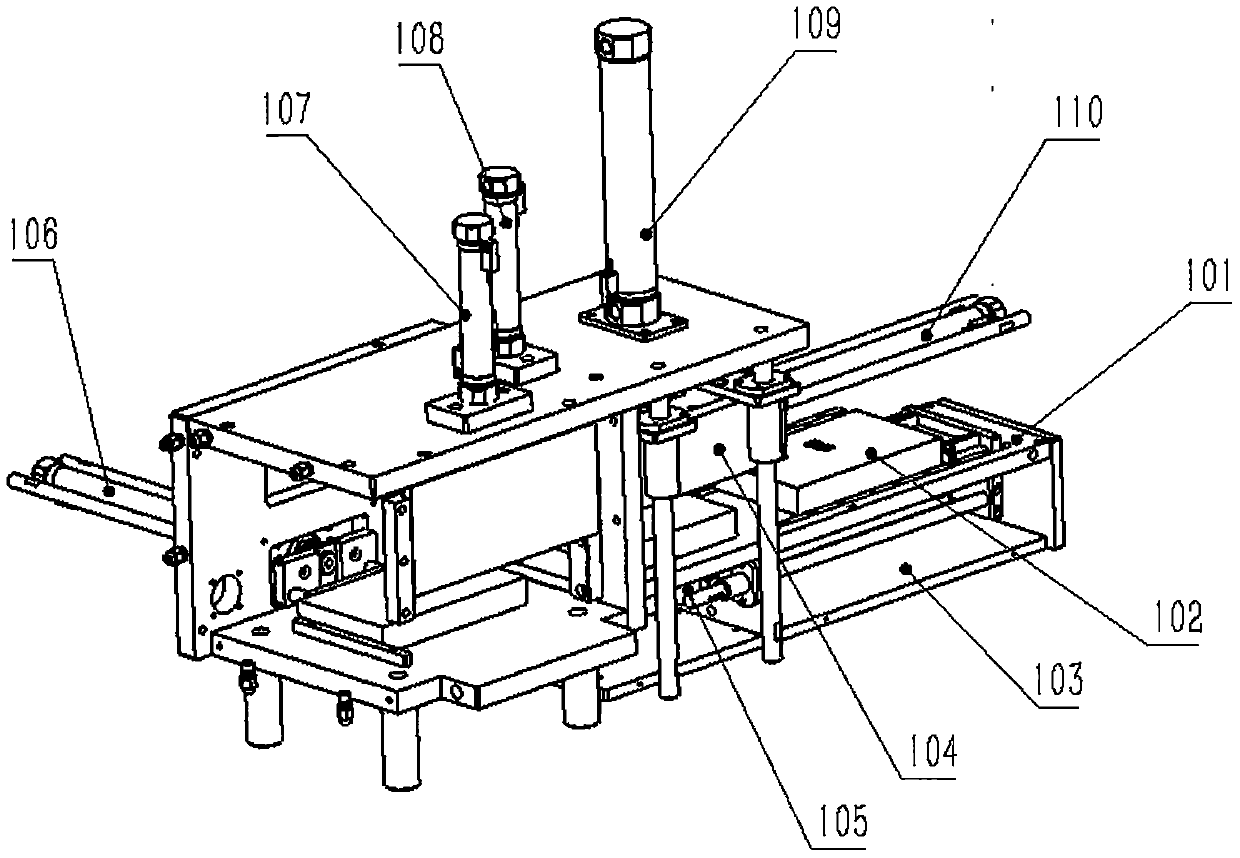

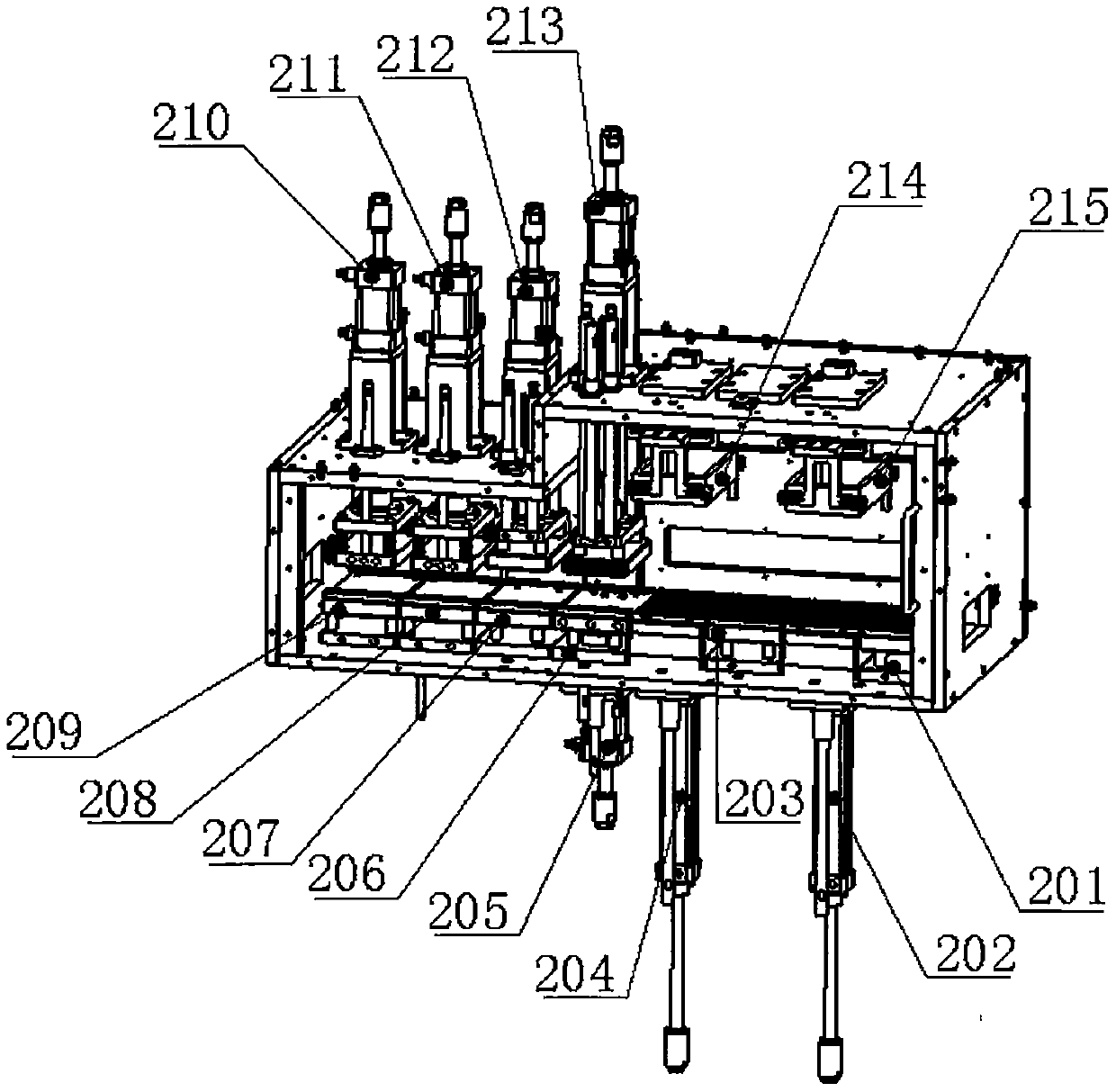

[0020] see Figure 1-3 , a glass hot bending equipment, comprising a base 4, a PLC control system 5, a feed device 1, a processing device 2 and a discharge device 3, the PLC control system 5, a feed device 1, a processing device 2 and a discharge device The devices 3 are installed on the upper end of the base 4, the feeding device 1 and the discharging device 3 are installed on both sides of the base 4, the processing device 2 is located between the feeding device 1 and the discharging device 3, and the PLC control system 5 is located One side of the feeding device 1, the feeding device 1 includes a feeding position 101, a mold 102, a pre-protection box 104, a cylinder and a feeding door, and the cylinder includes a first feeding cylinder 105, a second feeding cylinder 110, a third feeding cylinder Material cylinder 106 and box cylinder 109, feed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap