A preparation method of two-component bagged concrete

A preparation method and concrete technology, applied in the field of construction engineering, can solve the problems of high requirements for concrete, affecting the progress of the project, scattered parts, etc., and achieve the effect of making full use of resources, satisfying rapid installation and flexible preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

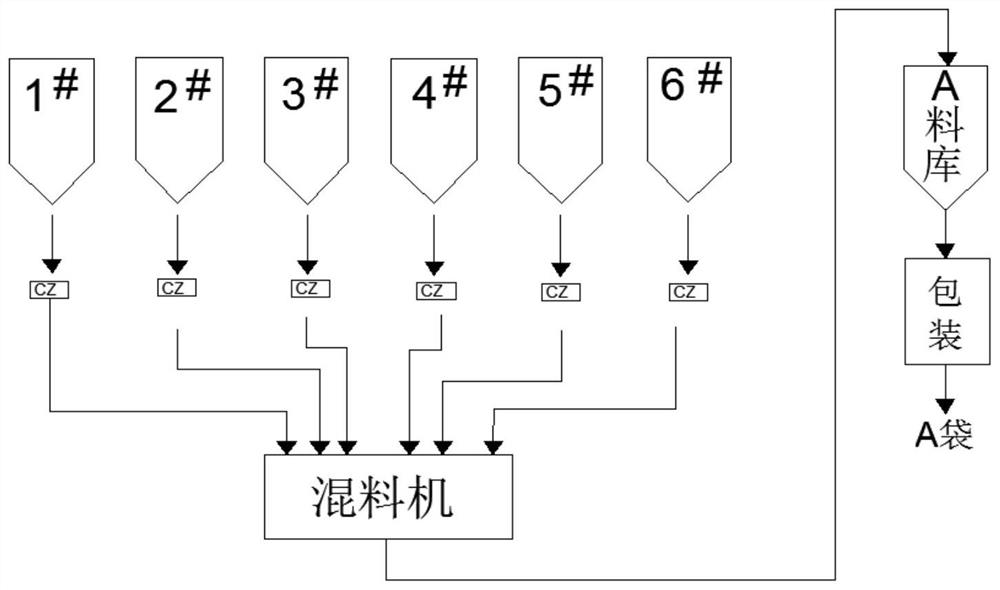

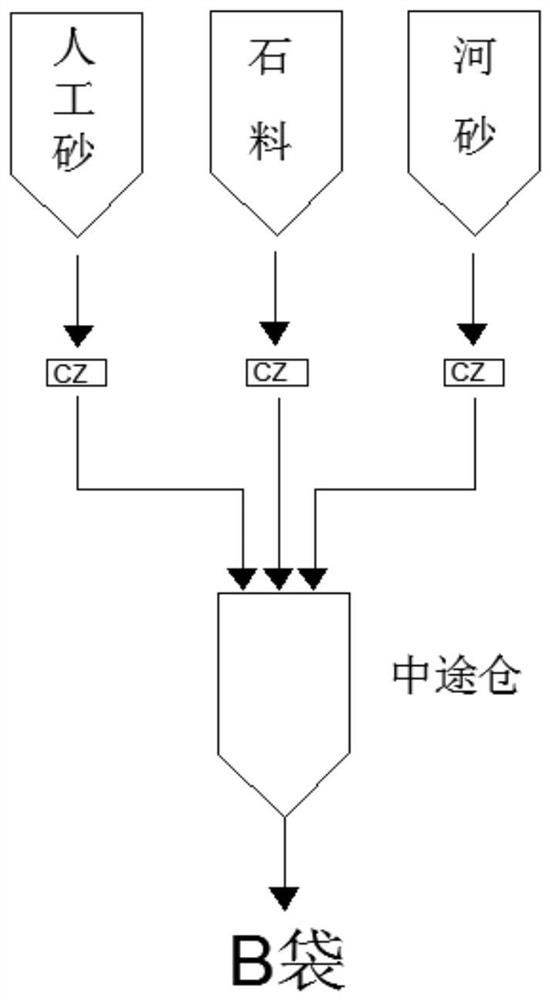

Image

Examples

Embodiment 1

[0026] A residential house in a new rural demonstration community adopts a prefabricated monolithic roof. The amount of concrete used for the joints of precast concrete components is less, and the total amount used at one time is only 0.2m 3 , only 10 groups are needed, that is, 10 packs in bag A and 10 packs in bag B. The proportion of concrete is as follows: A component is composed of 70% P II42.5 cement, 4% II grade fly ash, 24% mineral powder, 1.2% sodium sulfate and 0.8% dry powder polycarboxylate superplasticizer, A group After the distribution system, it is divided into 8Kg / bag; component B is composed of 38% artificial sand (water content 5%) and 62% 5-20mm gravel (moisture content 0.8%), that is, each bag uses 15.96Kg artificial It is made of wet sand and 25Kg of crushed stone, so that the weight of bag B is 40.96Kg (water content), and the two bags of A and B in each group are unpacked and mixed well, and 1.85Kg of water is added, and the slump of the mixed concrete...

Embodiment 2

[0028] A self-built house of a rural resident is a brick-concrete bungalow with a sloping roof. Bottom beams, wall columns, ring beams, etc. are all cast-in-place. Due to the small amount of single-cast concrete, the purchase of commercial concrete and the difficulty of self-mixing concrete, it is decided to use bagged C30 concrete. The proportion of A bag is as follows: 68% P·II42.5 cement, 6.8% Class II fly ash, 24% mineral powder, 1.2% naphthalene powder water reducer, after preparation, repackage, A weight is 7.5Kg / bag; B component is composed of water 4.5% medium sand (equivalent to 36% dry sand) and 5-20mm (equivalent to solid content 64%) crushed stones with a moisture content of 0.5%. Each bag is composed of 15.24Kg wet sand and 26.05Kg wet stone. 41.29Kg, A / B is 1 / 5.4, manual mixing after unpacking, adding 1.84Kg of water to each group, the slump is 7cm, after testing, the concrete strength at 7d is 25MPa, and the compressive strength at 28d is 34MPa.

[0029] When b...

Embodiment 3

[0031]A school education building is assembled with prefabricated components. In order to catch up with the progress, the compressive strength of the joint concrete is required to be no less than 25MPa in 24 hours. The component A is composed of 70% P II52.5 cement, 22.5% mineral powder, and 3% I grade Fly ash, 2% silicon powder, 1.3% sodium sulfate, 0.2% sodium silicate powder, 1% dry powder polycarboxylate superplasticizer, after preparation, it will be repackaged, each bag weighs 8Kg, and component B consists of 36% Artificial sand and 64% 5 ~ 20mm crushed stone components, because both aggregates contain water, the artificial sand contains 4% water, and the crushed stone contains 0.7% water, that is, each bag is prepared with 14.98Kg artificial wet sand and 25.78Kg crushed stone Formed, the B bag weighs 40.76Kg after containing water. When mixing each group of materials, 2.1Kg of water is added. After testing, the 24h compressive strength is 30MPa, which meets the engineer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com