Zinc pot stabilization process control method for hot galvanizing procedure

A hot-dip galvanizing, artificially controlled technology, applied in hot-dip galvanizing process, metal material coating process, coating and other directions, can solve problems such as affecting quality, suppress production and flow, reduce disturbance and flow impact, and stabilize heat. Compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

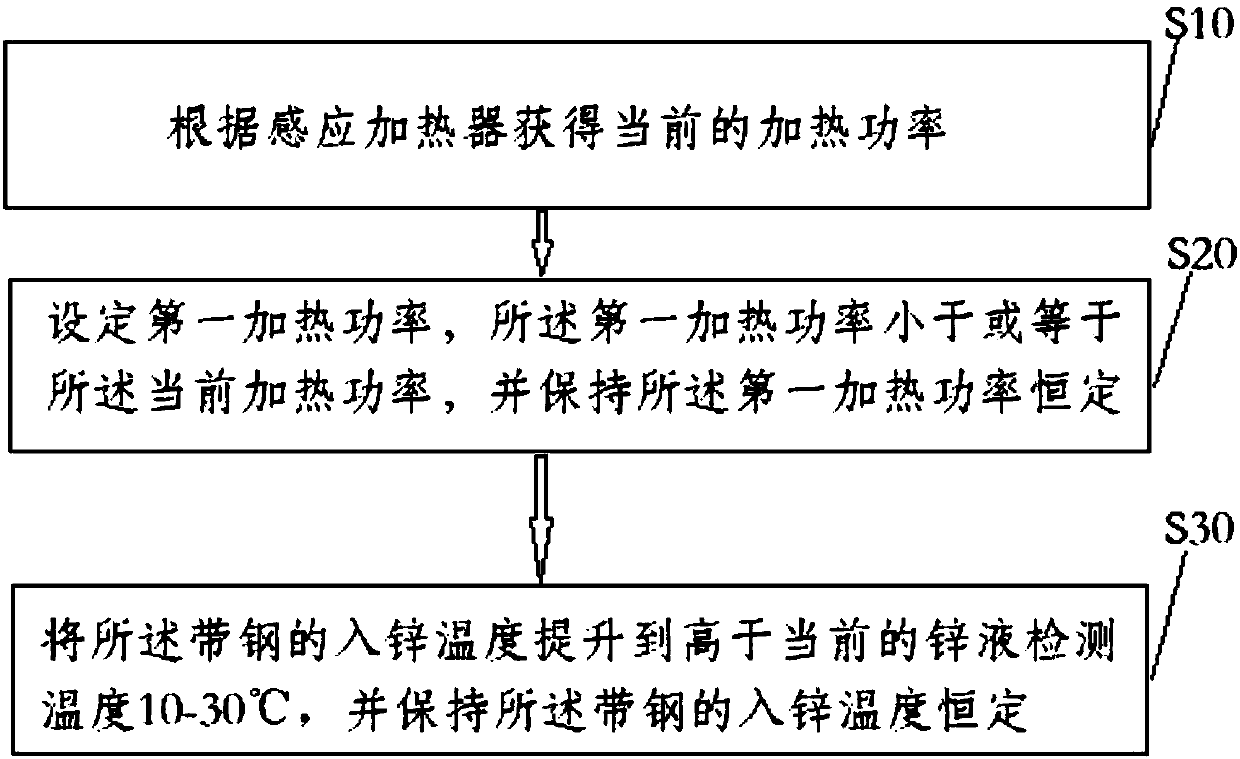

[0024] The embodiment of the present invention provides a zinc pot stabilization process control method applied to the hot-dip galvanizing link, such as figure 1 As shown, the method includes:

[0025] Step 10: Obtain the current heating power according to the induction heater 5;

[0026] Specifically, the processing power obtained by the induction heater 5 is the current heating power to keep the temperature inside the zinc pot 1 constant.

[0027] Step 20: setting a first heating power, the first heating power is less than or equal to the current heating power, and keeping the first heating power constant;

[0028] Specifically, the first heating power is set according to the current power obtained by the induction heater 5, the first heating power is less than or equal to the current power, and the first heating power is kept constant to maintain The temperature in the zinc pot 1 is kept constant, the stable state of the zinc liquid 2 in the zinc pot 1 is maintained, and ...

Embodiment 2

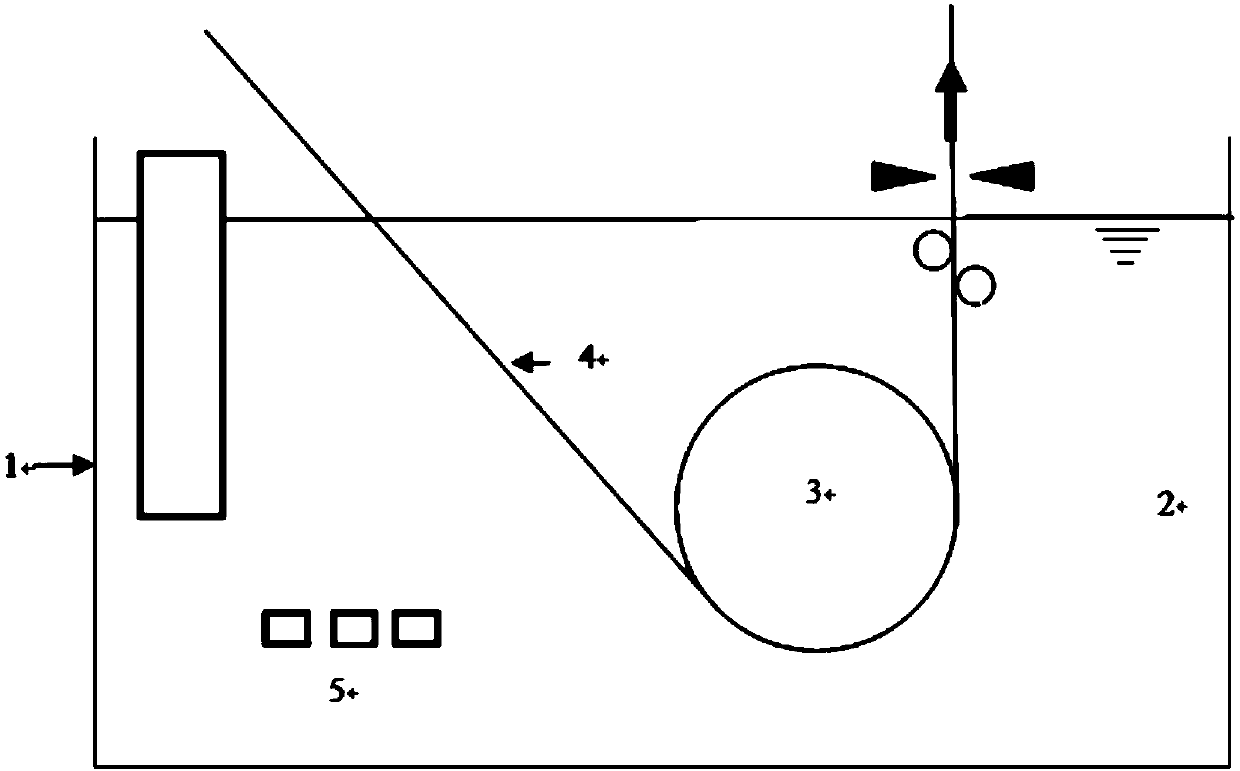

[0042] A method of zinc pot stabilization process control applied to the hot-dip galvanizing link of the present invention is described in detail below, please refer to figure 2 , image 3 ,details as follows:

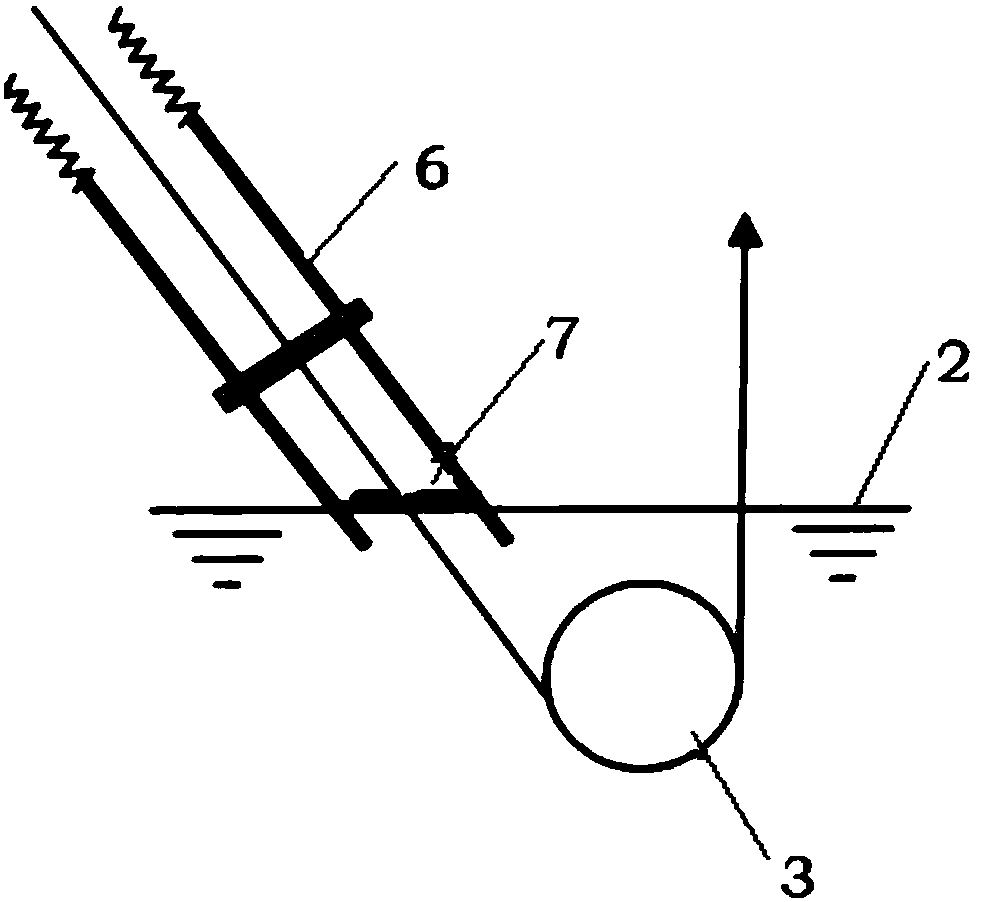

[0043] In the embodiment of the present invention, a zinc pot stabilization process control method applied to the hot-dip galvanizing process is provided, which is mainly aimed at the current hot-dip galvanizing process for cold-rolled sheets. Some impurities will affect the quality of the galvanized surface. Zinc slag 7 is the most typical defect, such as image 3 As shown, the zinc slag 7 accumulates at the bottom of the furnace nose 6, and when the strip steel 4 enters the zinc liquid 2 through the furnace nose 6, the zinc slag 7 is easily brought in together, resulting in a reduction in the surface quality of the strip steel 4 electrogalvanized sheet and affecting downstream products the quality of. Through a zinc pot stabilization process control method applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com