Environment-friendly coating for high speed

An environmentally friendly coating and high-speed technology, applied in the field of paper coatings, can solve the problems that the strength and running suitability of biological adhesives cannot be satisfied at the same time, the surface strength of coated paper paper decreases, and the negative impact of paper printing effects, etc., to achieve good paper machine Runnability, excellent printing quality, effect of less usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

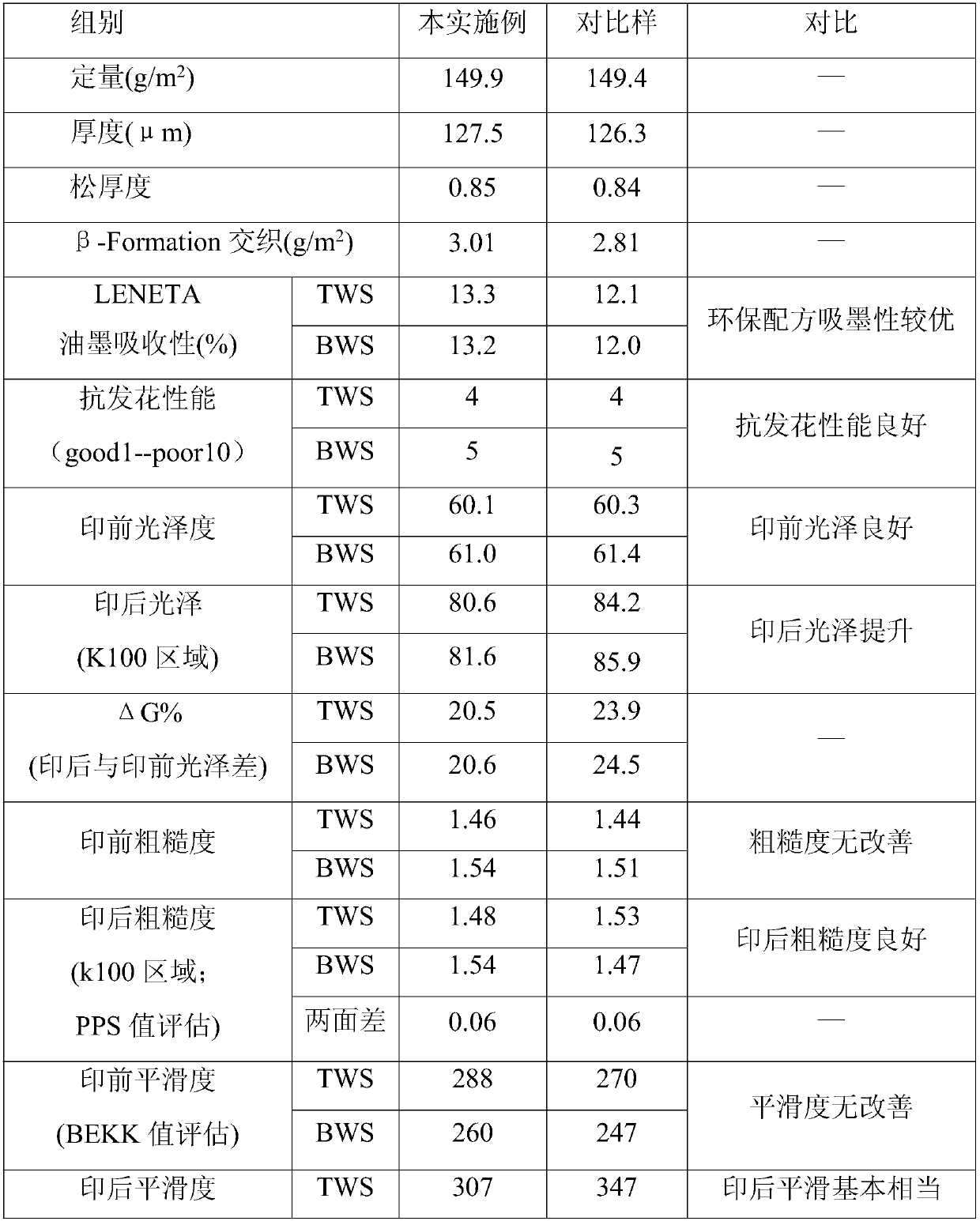

Embodiment 1

[0023] An environmentally friendly paint for high vehicle speeds, the paint formulation includes pre-coat paint, mid-coat paint and top-coat paint;

[0024] The pre-paint formula includes grinding calcium carbonate, latex, bio-adhesive and thickener; the solid content is 58%, the viscosity is 280cps, and the pH is 8.8; wherein the parts by weight of each component: grinding calcium carbonate<2um accounts for 100 parts of 60-65% C65 grade, 17 parts of bio-adhesive;

[0025] The formula of the intermediate coating includes ground calcium carbonate, bio-adhesive, latex and thickener; the solid content is 62%, the viscosity is 450cps, and the pH is 8.8; wherein the parts by weight of each component: ground calcium carbonate<2um accounts for 60-65% C65 grade 100 parts, bio-adhesive 7 parts, latex 4 parts, thickener 0.25 parts;

[0026] The formula of the top coating paint includes ground calcium carbonate, china clay, bio-adhesive, latex and thickener; the solid content is 66%, th...

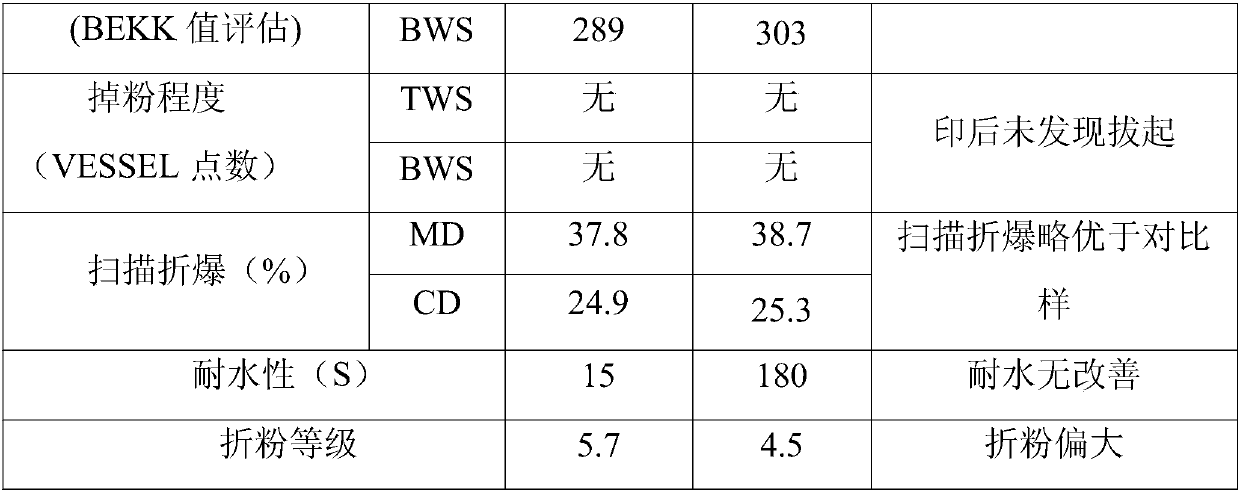

Embodiment 2

[0040] An environmentally friendly paint for high vehicle speeds, the paint formulation includes pre-coat paint, mid-coat paint and top-coat paint;

[0041] The pre-paint formula includes ground calcium carbonate, latex, bio-adhesive and thickener; the solid content is 66%, the viscosity is 250cps, and the pH is 10.3; wherein the parts by weight of each component: ground calcium carbonate<2um proportion 60-65% C65 grade 100 parts, latex 2 parts, bio-adhesive 12 parts, thickener 0.3 parts;

[0042] The formula of the intermediate coating includes ground calcium carbonate, bio-adhesive, latex and thickener; the solid content is 62-67%, the viscosity is 450cps, and the pH is 10; wherein the parts by weight of each component: ground calcium carbonate<2um Accounting for 60-65% 100 parts of C65 grade, 11 parts of bio-adhesive, 1 part of latex, 0.5 parts of thickener;

[0043]The formula of the top coating paint includes ground calcium carbonate, china clay, bio-adhesive, latex and ...

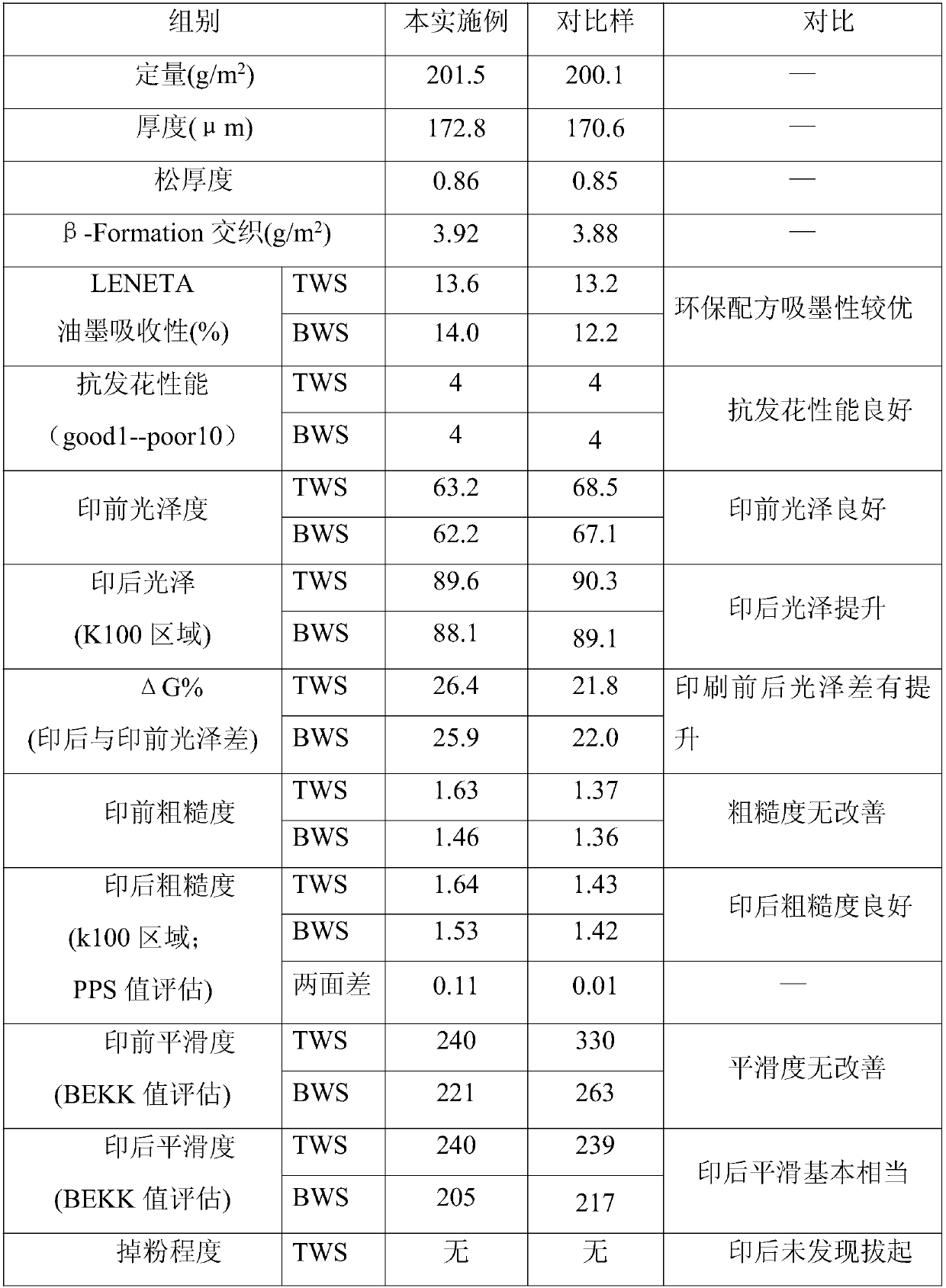

Embodiment 3

[0057] An environmentally friendly paint for high vehicle speeds. The paint formula is divided into three types, namely pre-coat, middle coat and top coat; the pre-coat paint formula includes ground calcium carbonate, bio-adhesive and thickener; The content is 58.5%, the viscosity is 220cps, and the pH is 9.9; the parts by weight of each component are: ground calcium carbonate <2um, accounting for 60-65%, 100 parts of C65 grade, 15 parts of bio-adhesive, and 0.19 parts of thickener; The formula of the intermediate coating includes grinding calcium carbonate, bio-adhesive, latex and thickener; the solid content is 66.5%, the viscosity is 430cps, and the pH is 9.5; wherein the parts by weight of each component: grinding calcium carbonate<2um accounts for Ratio 60-65% C65 grade 100 parts, bio-adhesive 10 parts, latex 1 part, thickener 0.46 parts; the top coating formula includes ground calcium carbonate, china clay, bio-adhesive, latex and thickener The solid content is 69.5%, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com