Method for manually breaking inner support beams

A technology of supporting beams and labor, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of high operation expertise, structural safety impact, and high construction cost, and achieve improved labor efficiency, convenient cleaning and transportation, and small safety risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following non-limiting examples illustrate the invention.

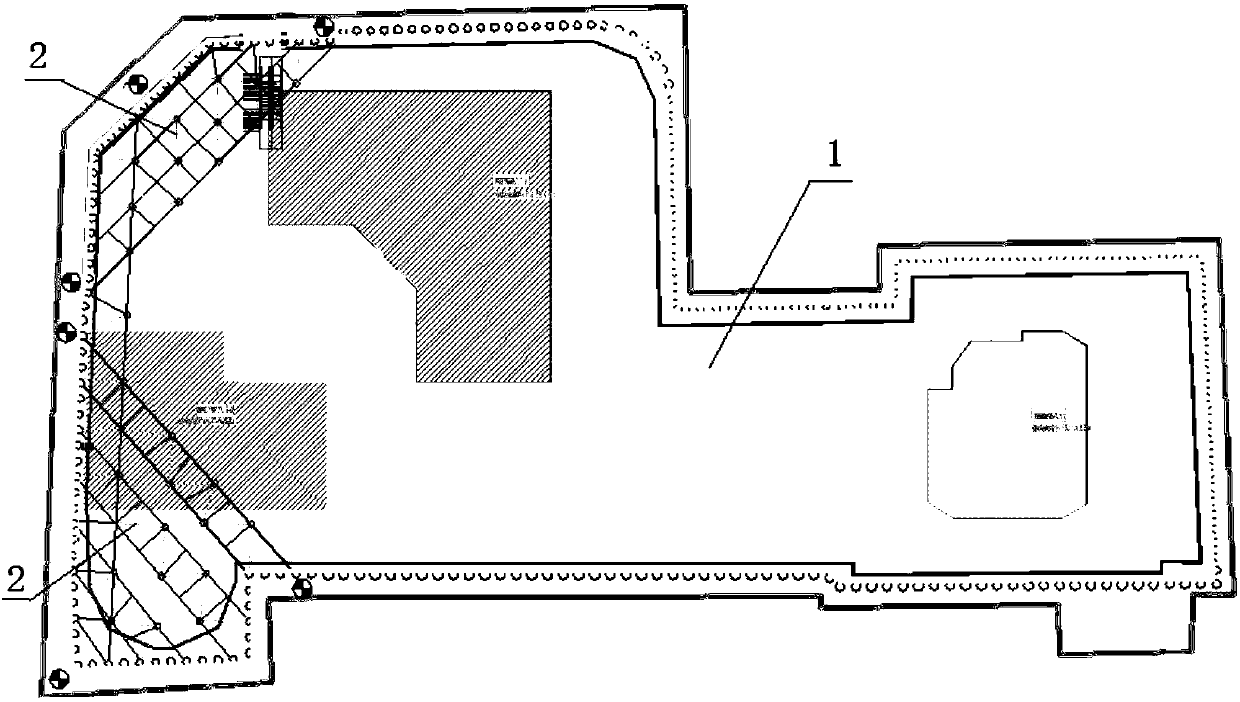

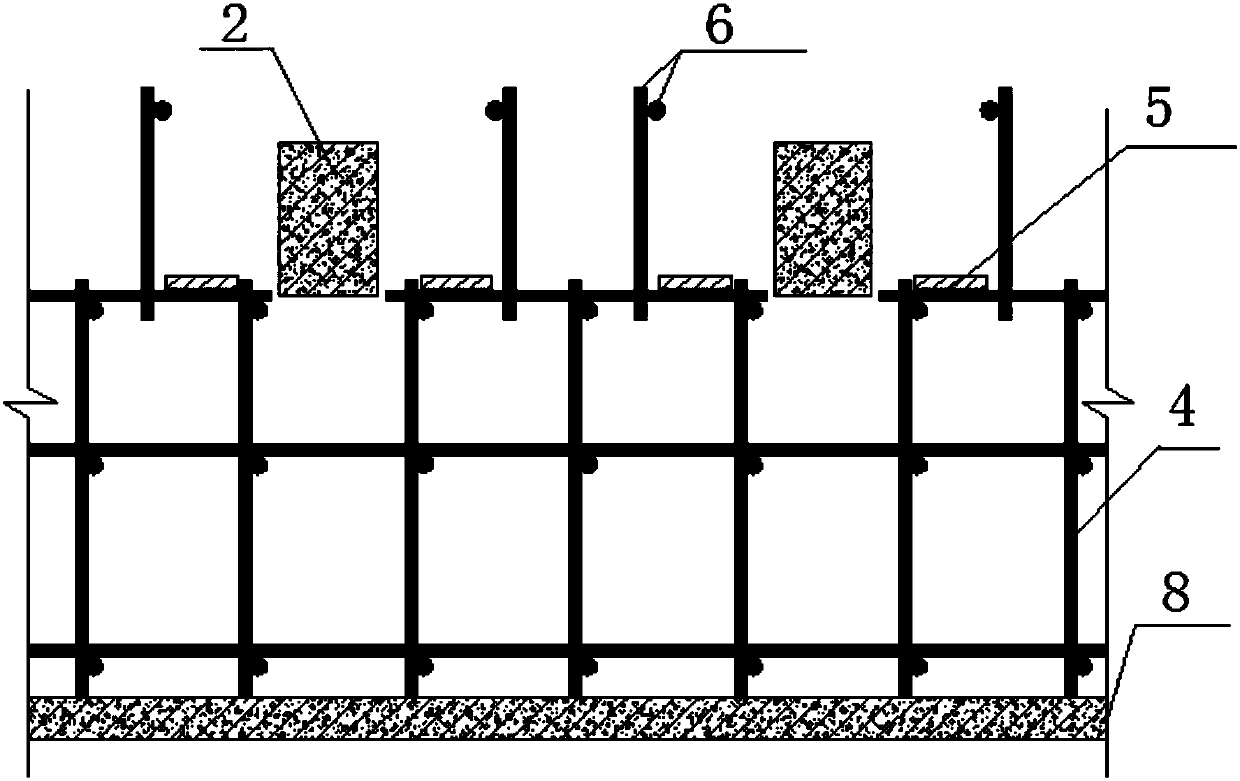

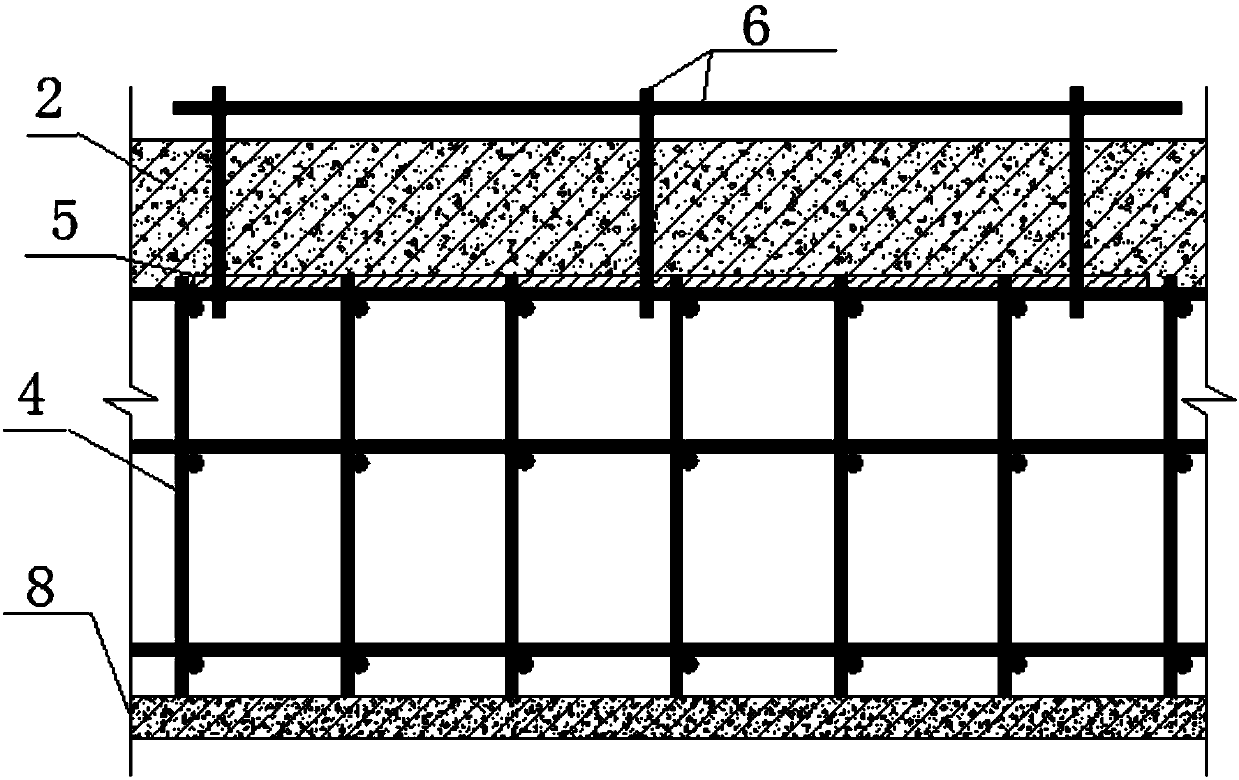

[0026] refer to figure 1 As shown, the surrounding conditions of a project site are complicated and the construction site is limited. According to the distribution of surrounding buildings and site construction requirements, combined with geological engineering conditions, two methods of anchor pile + internal support are adopted. The foundation pit 1 adopts the combined support of bored piles and anchor cables combined with internal supports, and adopts the form of vertical support. The bored pile diameters are 1200mm and 1500mm, and the concrete strength grade of the pile body is C30 (the lmna section adopts C35). The inner support is jointly supported by the inner support beam 2 and the steel lattice column 3, and the concrete strength grade of the inner support beam 2 is C30.

[0027] Dimensions and labels of support beams in the basement

[0028] name

size

Cross-sectional area m 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com