Cast-in-place concrete plus axillary wall aluminum alloy chamfering formwork support and fixing device and method

A formwork support and fixing device technology, which can be used in formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve formwork deformation, on-site worker injury, resistance to problems such as poor buoyancy, to prevent displacement, ensure construction quality, and improve installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

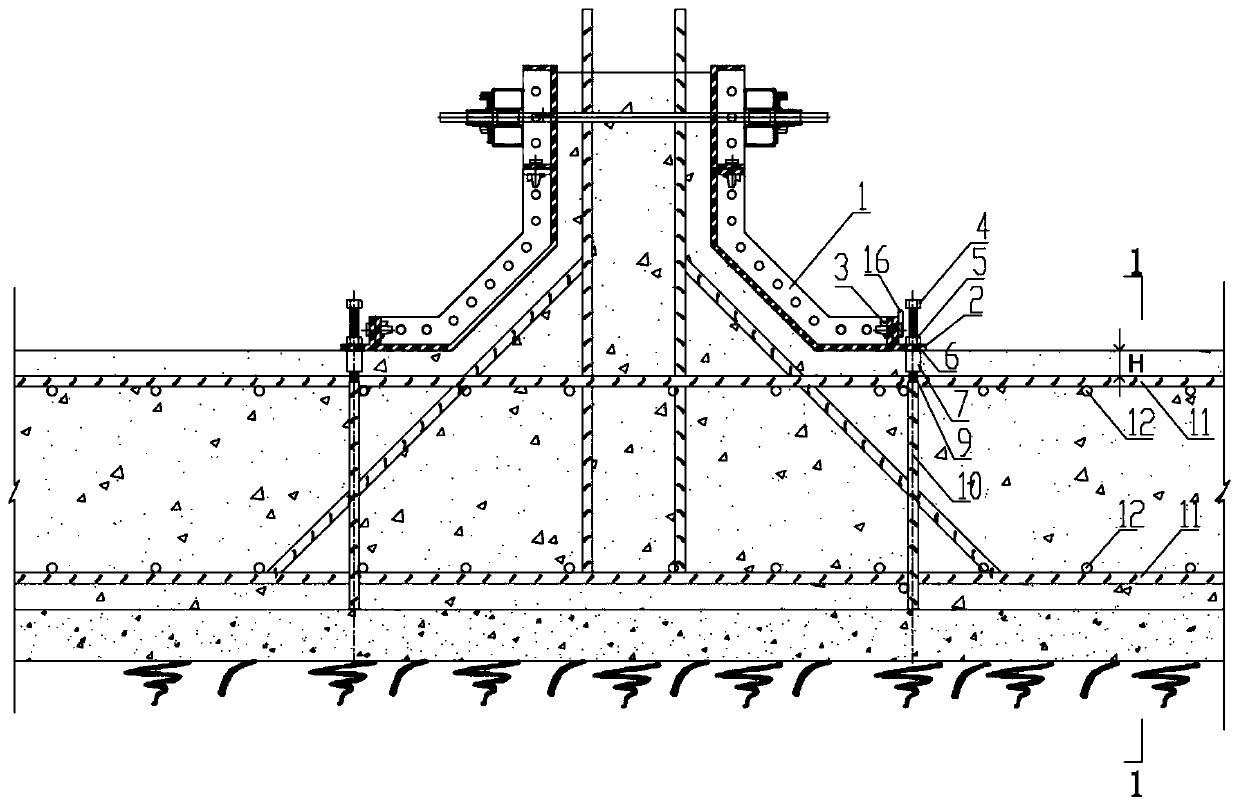

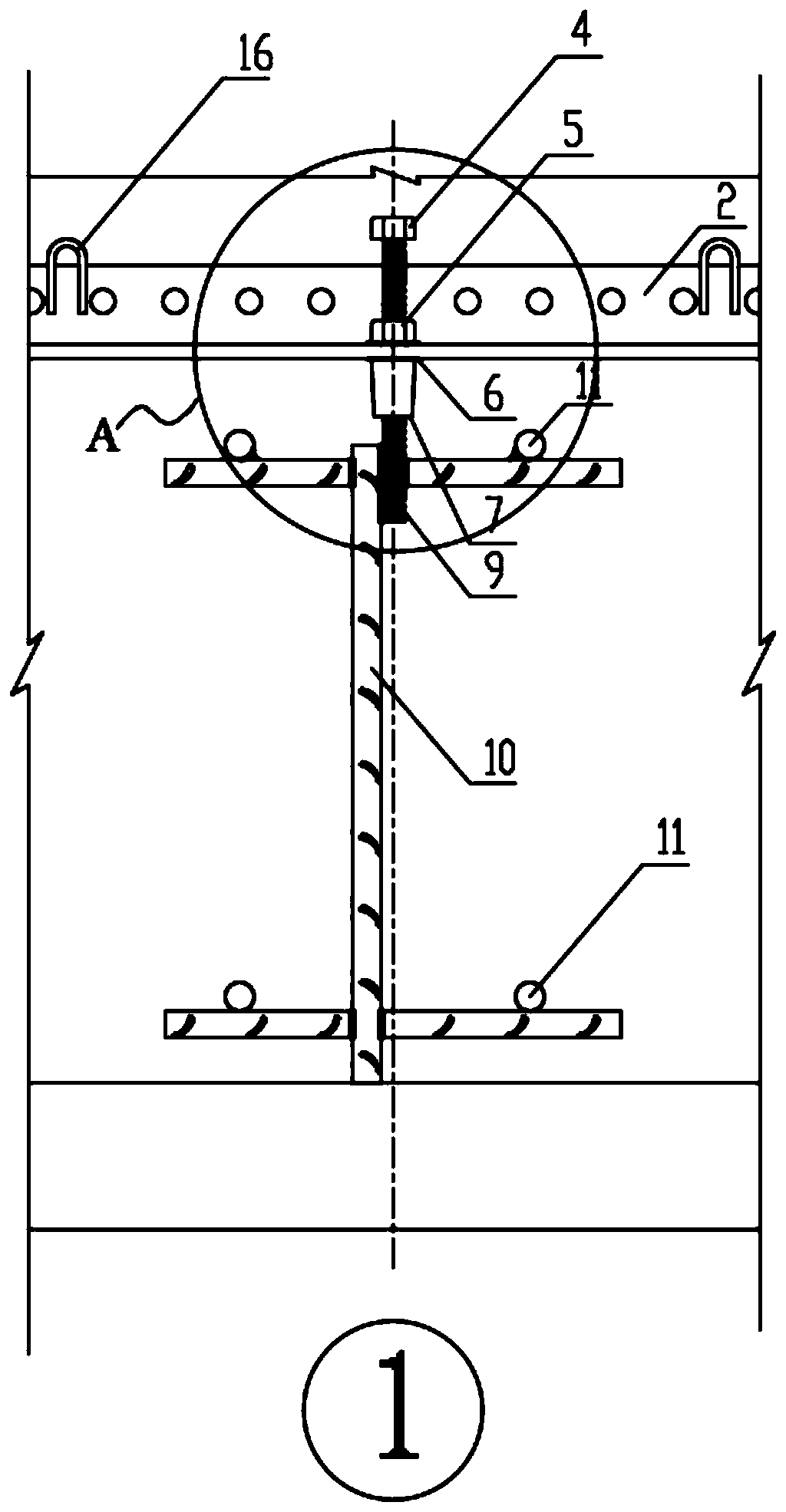

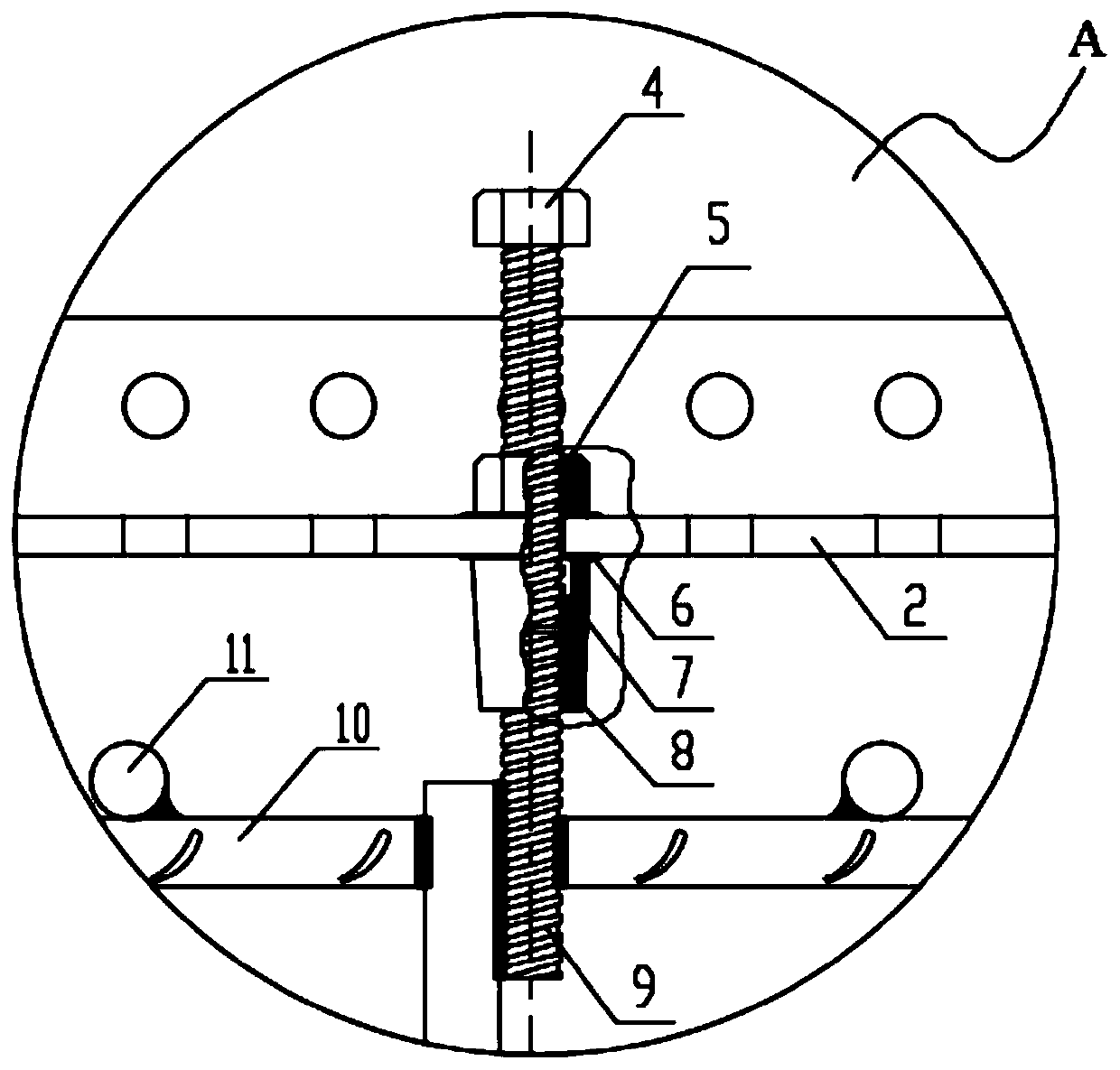

[0072] (1) Axillary chamfering template supporting and fixing device

[0073] The supporting and fixing device of this embodiment consists of an I-shaped support frame 10, a screw rod 9, a tapered cover 7, a tapered sleeve 8, a washer 6, a right-angle connector with a pull ring 16, a hexagonal nut 5 and a bolt 4. composition. See the decomposition structure of the supporting and fixing device in this embodiment Figure 4 , See the structure of nut, gasket, cone cover and cone sleeve Figure 5-8 ;

[0074] 1) The I-shaped support frame 10 is made of rebar processing surplus material, which is equivalent to the double-layer steel mesh of the bottom plate supporting the stirrup, without additional material cost;

[0075] 2) The screw 9 thread is matched with the taper sleeve 8, the nut 5, the bolt 4 thread, and it can be made with the remaining material of the drawing rod 9 through the wall for construction. The length of the screw 9 is not less than three times the bottom plate double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com